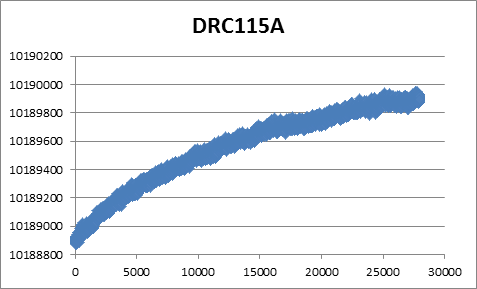

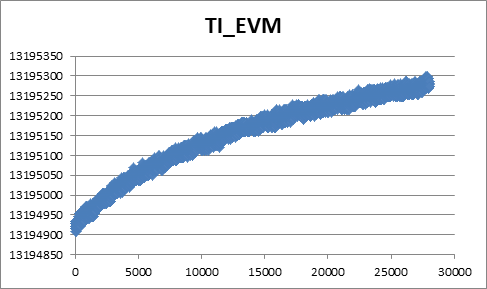

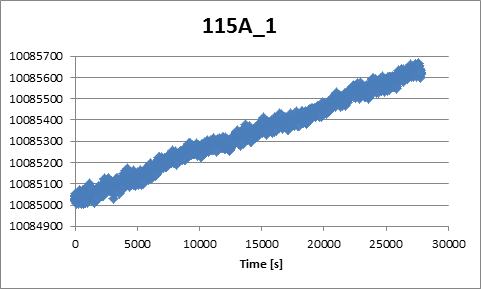

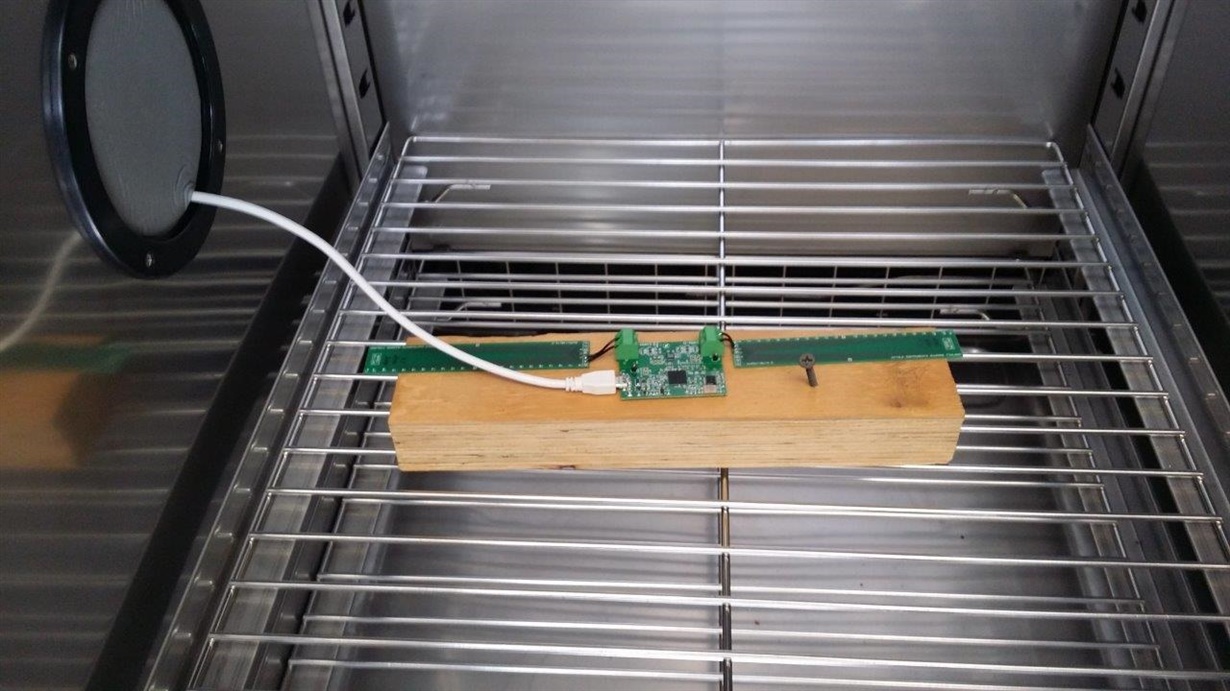

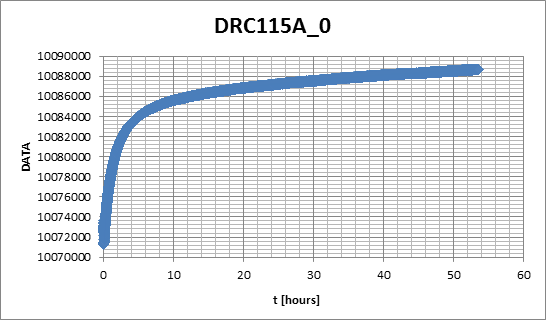

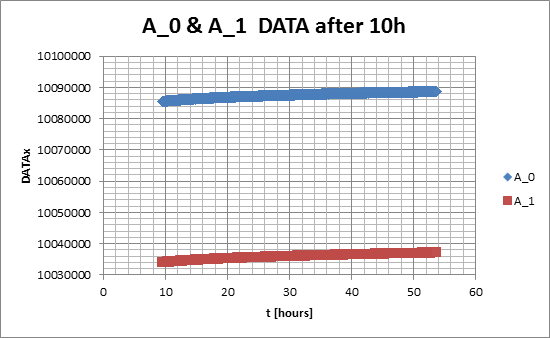

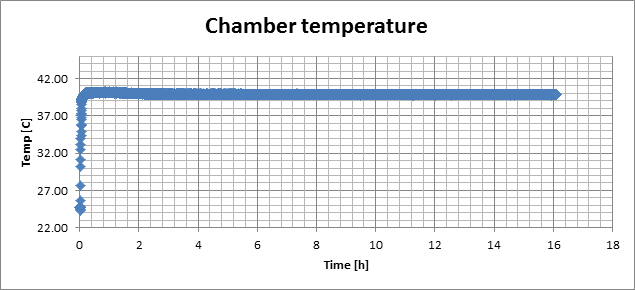

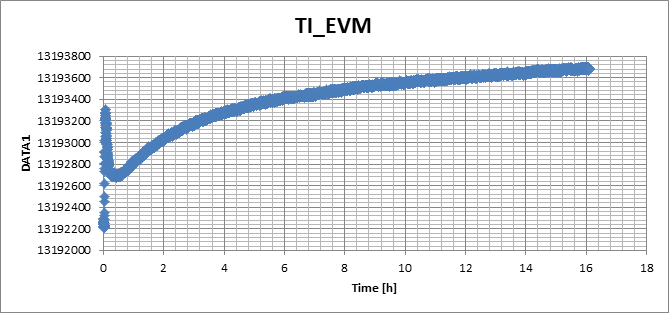

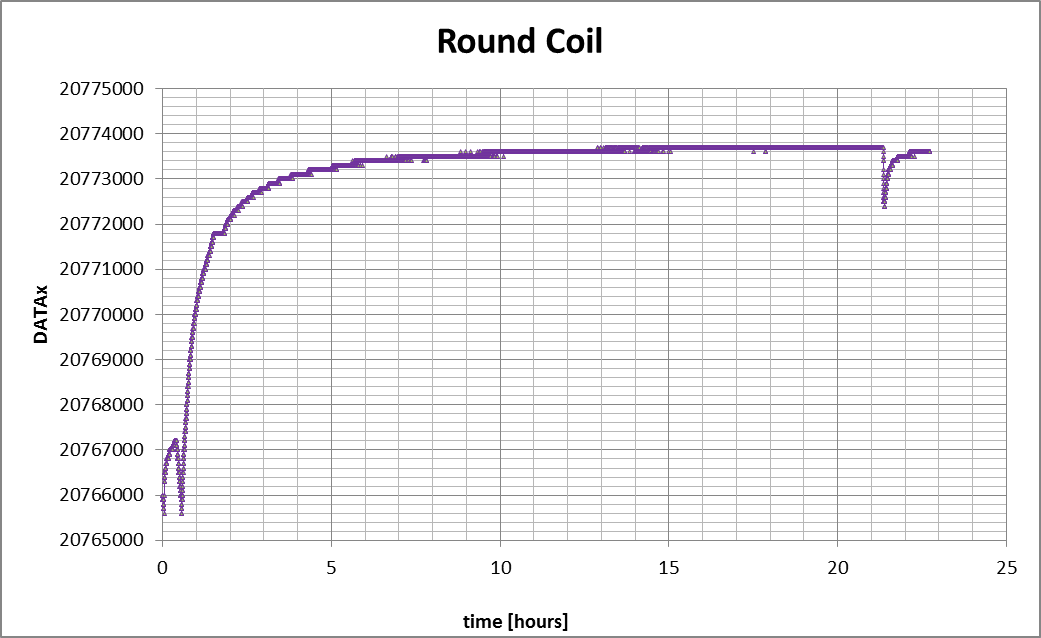

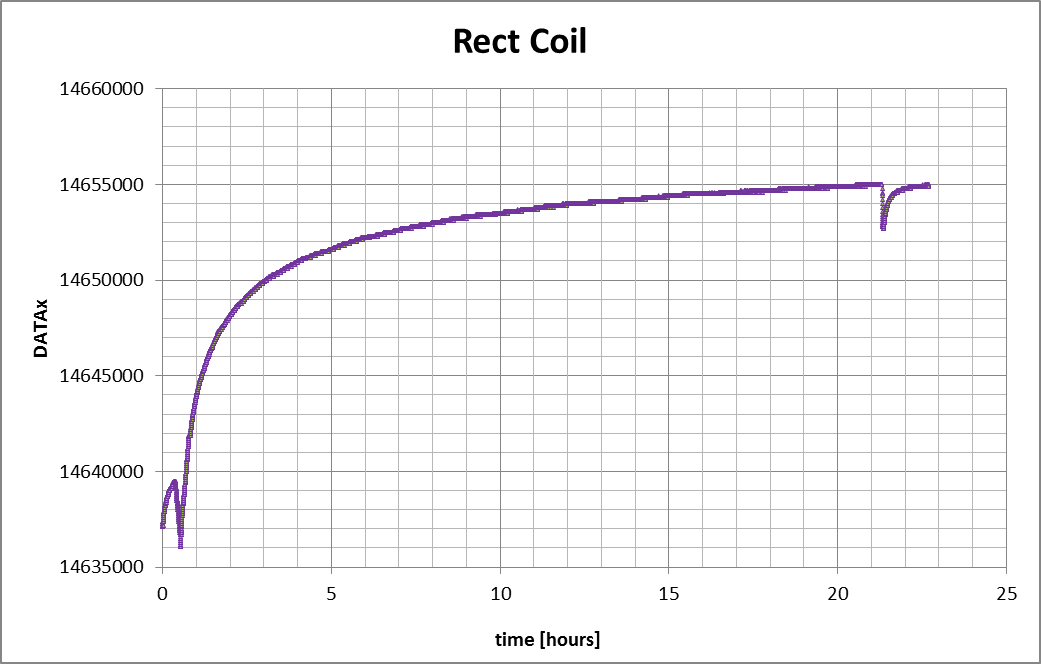

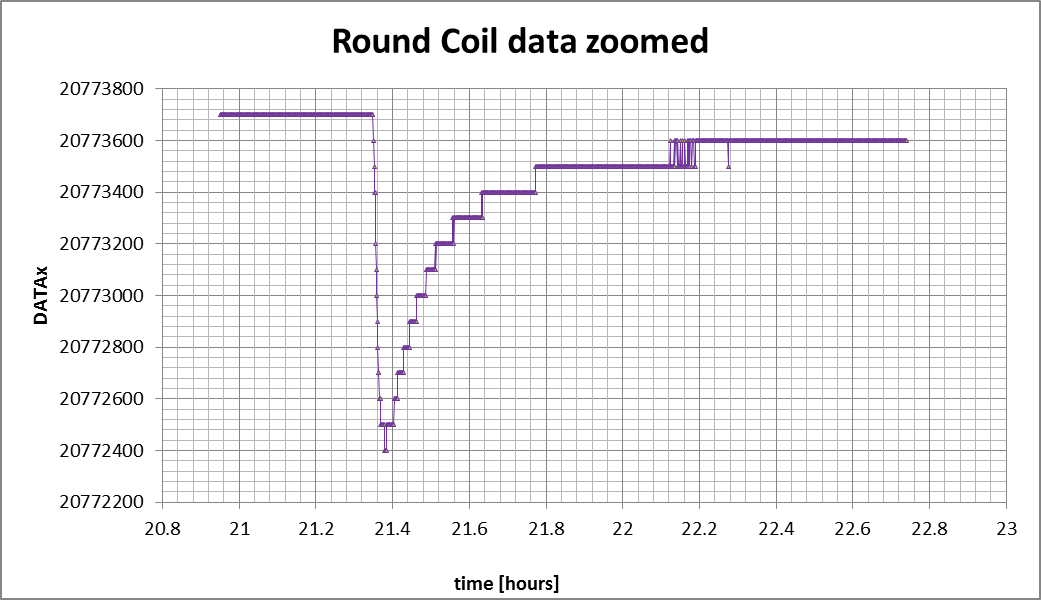

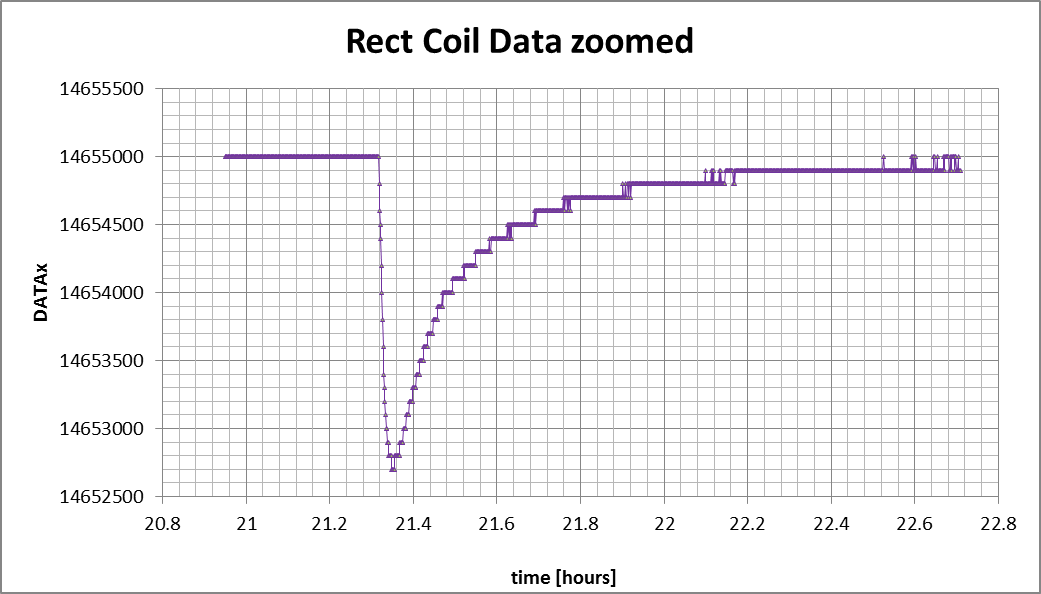

We have noticed that our rectangular 2-sided coils show a considerable drift that might be due to temperature. The drift can be order of thousands of units in couple of hours. In order to investigate this further we put the LDC1612EVM board with two coils into a oven. The temperature was 30C and we used our own coil as well as the circular coil that came with EVM. We assumed that the signal should be effectively a horizontal line with gaussian noise at least in the TI's coil, instead we got similar drift in both coils (see below). This is bit worrying as we use LDC1612 in linear position sensing and if the DC offsets in static temperature the product is unusable. The measurements below were made in period of 16 hours.

We also noticed that there is a transient during the first couple of minutes when the coil adjusts to the external temperature. After that the actual drift starts. Are we doing something very wrong with the measurement parameters. The electronics used in this test was the LDC1612 EVM.