Hello,

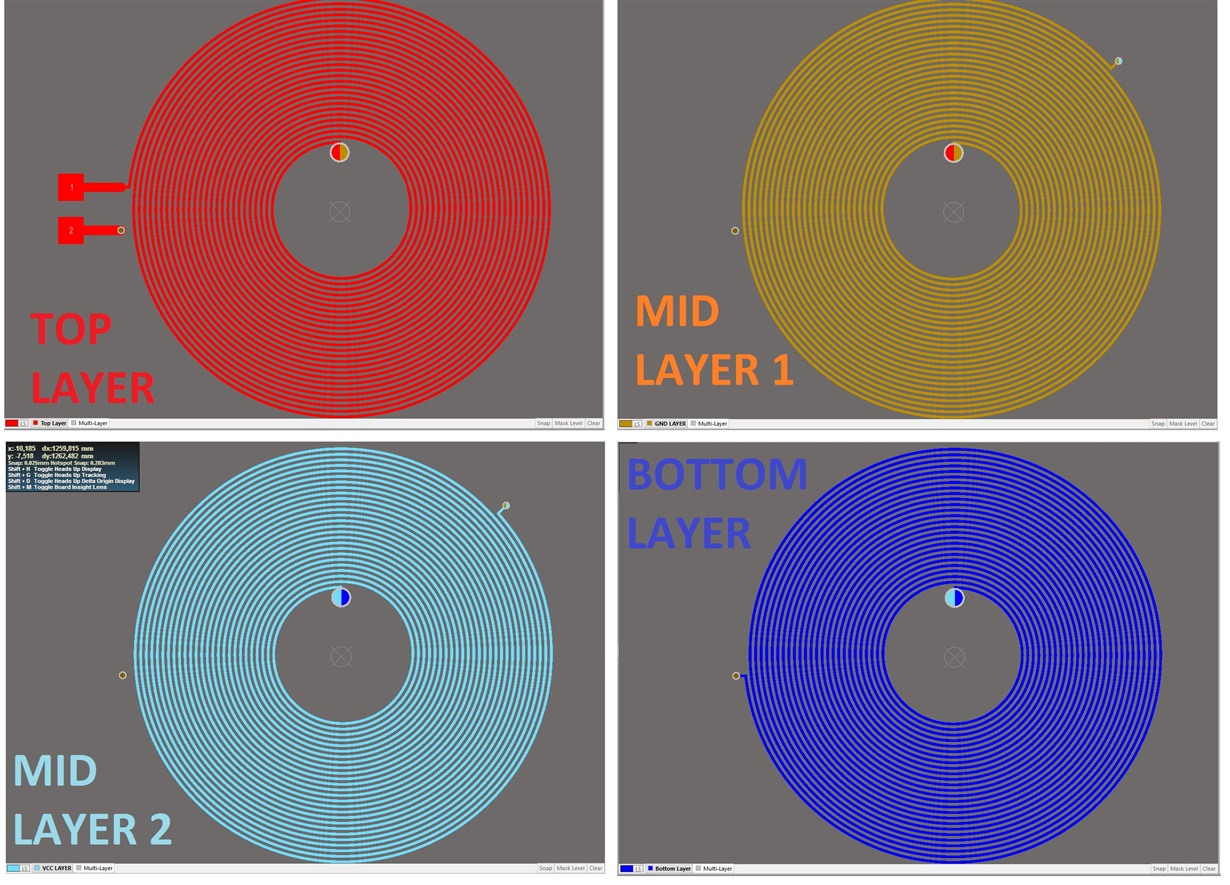

I'am using LDC1000 device with CTANK = 1nF and Lpcbcoil= 82uH (below the 4 layer PCB COIL LAYOUT used).

All vias are blind and buried, except that left via. The central via have a diameter of 0.6/0.8mm, while the others have a diameter of 0.2/0.3mm . The copper tickness of coil is 42um for external layer and 35um for mid-layer, and the coil external diameter is 15.6mm .

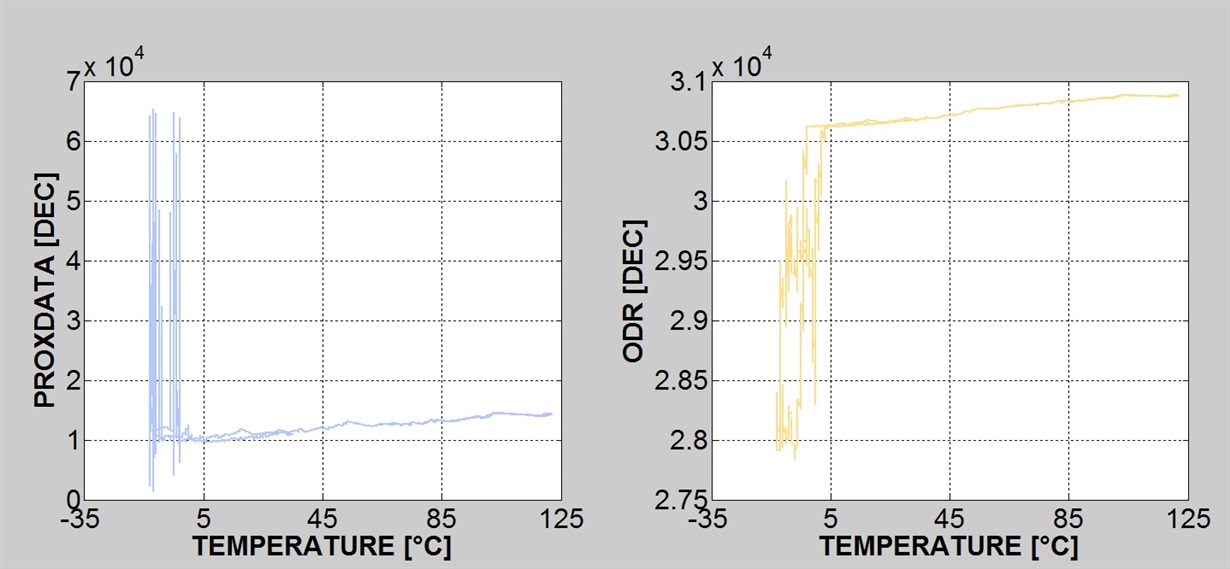

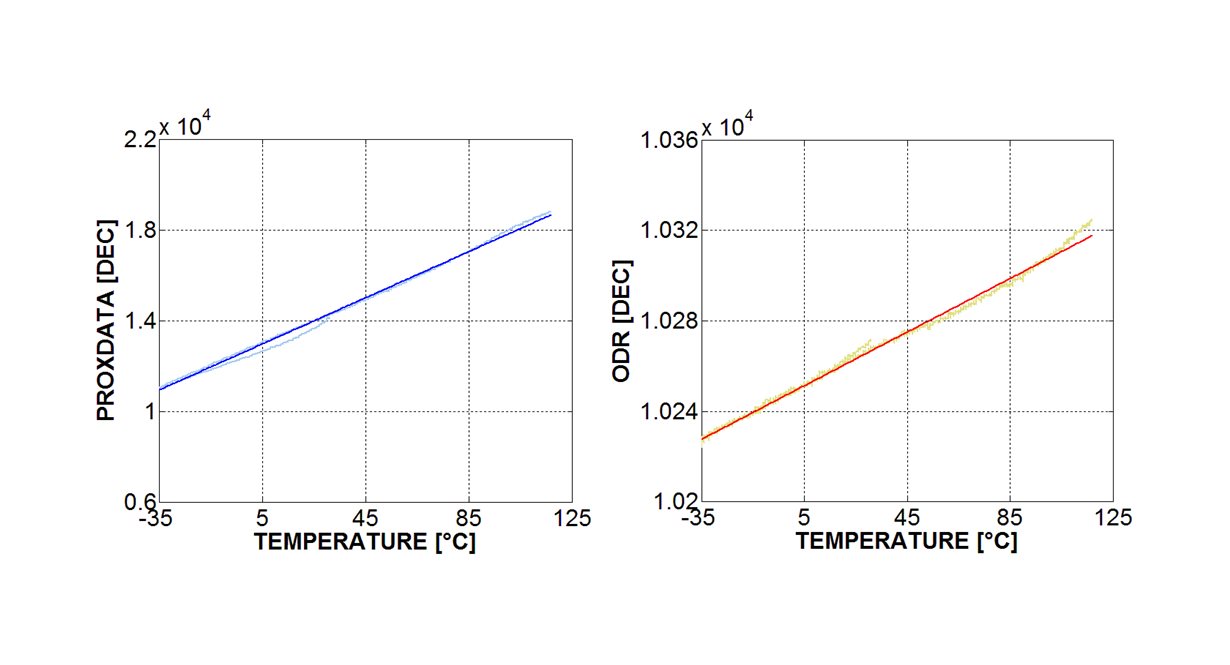

I performed a temperature test with this pcb coil, and I seen that for TEMP < 5°C, the ODR and PROXIMITY DATA behavorial is very strange (see below).

I take also care that the Rp escursion keep within the range [ 0.798 , 3926.991] kΩ .

Why does the COIL behave in this way ?? I think the problem is due to the geometry of COIL, but it's really so ??