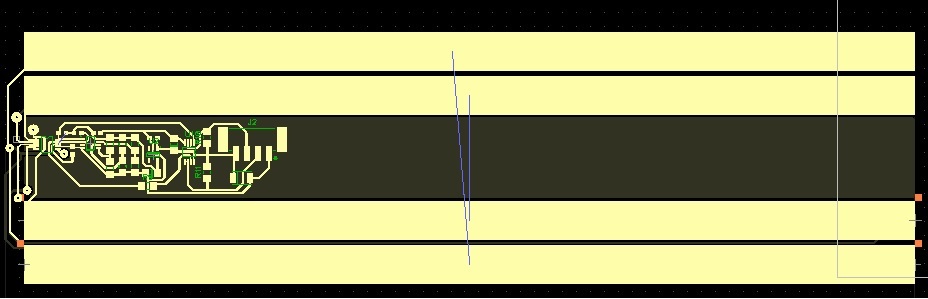

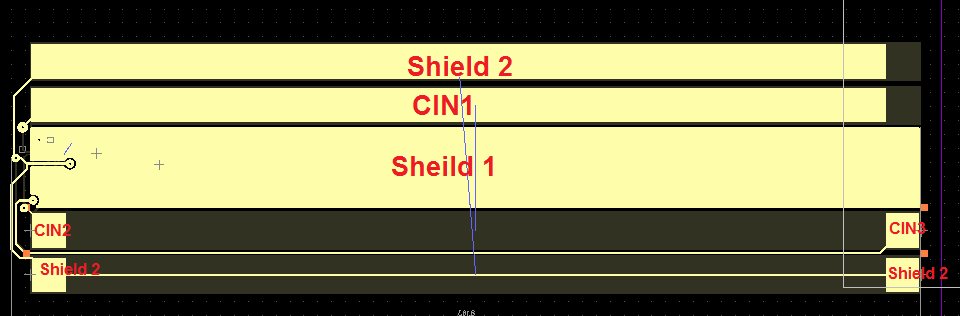

I have built a PCB similar to the design in your OOP paper TIDA-00317. The Cin1 sensor size is 8" x 0.31", and the reference sensors are 0.3" x 0.31".

The main difference in my design is that I placed all the circuitry including power supply, I2C transceiver, and the FDC1004 in the area between the sensing pads and the reference pads.

1.) I used Shield 1 to isolate below the circuitry, is this the right choice? Should I have used GND? I thought I might exceed the 400pF max on Shields then. Maybe I shouldn't have put any copper plane beneath the ICs? The area that I mention is the dark grey in the PCB

Top Side

2.) I can measure a result from both reference sensors that seems reasonable, but when I measure from CIN1, I get a 7FFFFF reading, maximum reading. I have cut the CIN1 trace and now get some value just below zero. Any thoughts? All CIN1, CIN2, and CIN3 are differential measurements against CIN4.