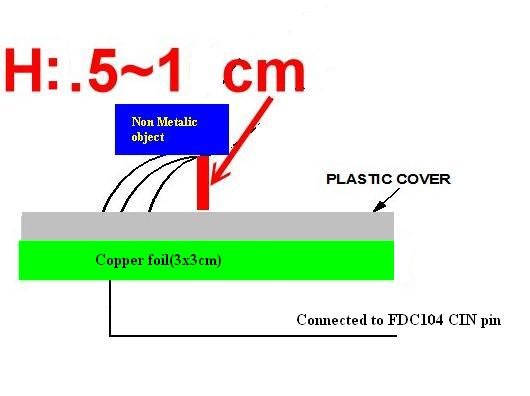

Hello everyone, I have been trying to detect non conductive objects using FDC1004EVM to test the Capacitance-to-Digital Converter FDC1004 but but I haven't been able to detect a significant change in capacitance (My setup is as in figure.).

The copper foil are is 3x3cm.The plastic cover thickness is around 3mm. The cable length is around 5~10cm.

When I tried to detect an plastic object the change in capacitance is around 0.2pf. I unsure as to how stable this value will remain.

Can you help me to have a better stable difference. what changes should I do to get better results.

Best Regards

Yesh