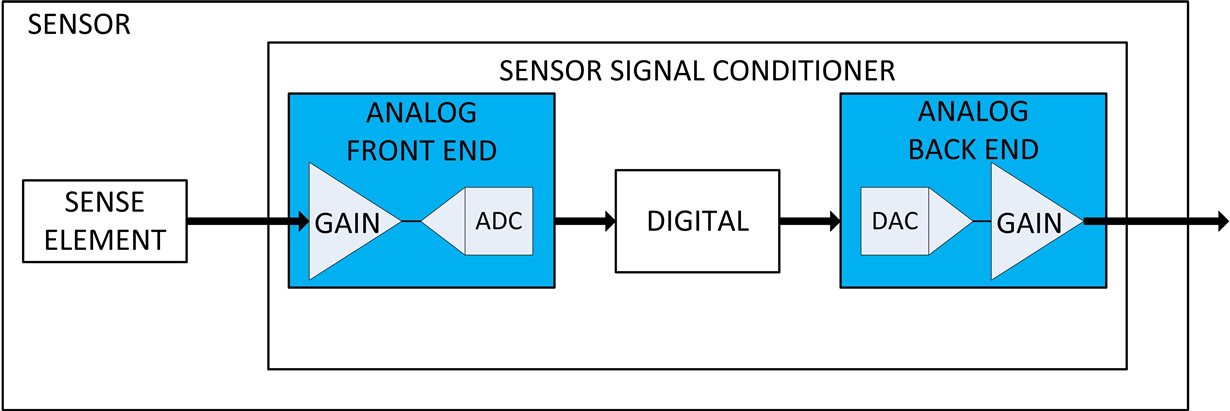

I have a simple sensor that I'd like to connect to the PGA900 and get a 4-20mA output. The image below shows the a schematic of the sensor.

I'm a little confused on what pins I should be connecting this sensor to. I have the PGA900 setup as described on page 119 of SLDS209A.

Any help or guidance would be greatly appreciated.

Thank you,