Hello,

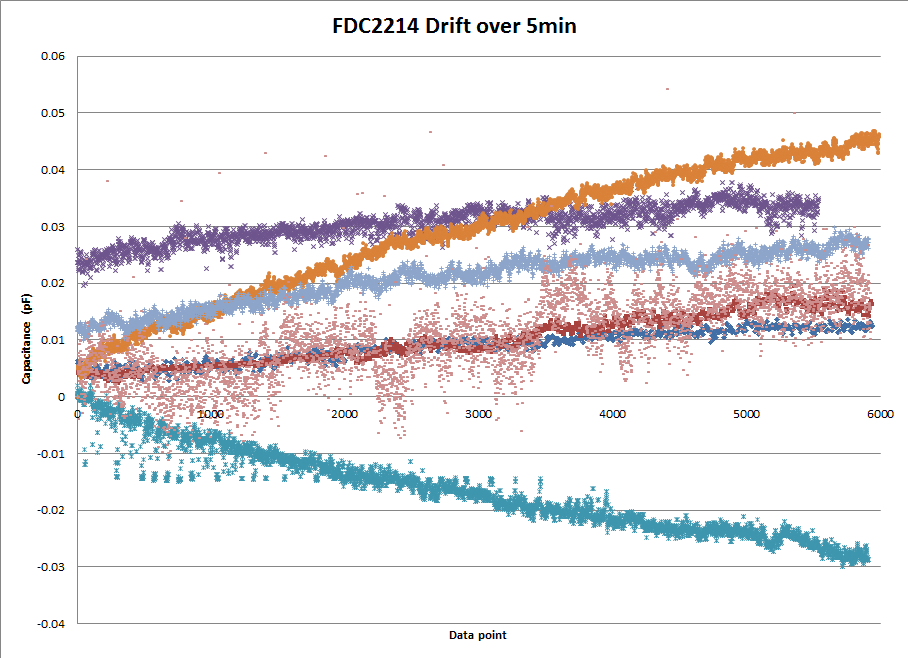

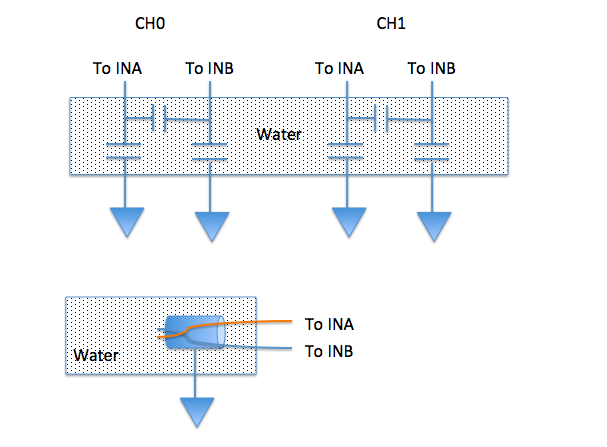

I am working with the FDC2214EVM and am noticing quite a bit of drift over time and was wondering what can be done to reduce the drift. I have my EVM mounted in a shielded enclosure and I am using a nice clean function generator. I even leave the room and remote into the computer to do the measurements to control any stray human capacitances. My EVM stays in the enclosure and the INA channel is wired to a connector on enclosure. I disconnected my sensor and capped the connector on the enclosure for the following drift measurements. Attached is a plot of several measurements over 5 minutes and the drift is up to 50 fF. The full range of my sensor is <130 fF so this drift can obscure a big portion of the range.

This drift does not seem environmental so I don't think I can go with a differential configuration. Plus, do to design constraints, I can only use a single-ended configuration.

Thank you!