Hello ...

I am currently designing a ldc0851.

I have some questions about documents and tool

documents and tools:

ldc0851 Differential Inductive Switch (Rev. A)

slyc137 Inductive Sensing Design Calculator Tool

WEBENCH Coil Designer

------------------------------------

Q1) 9.1.1.1 Sensor Frequency (Page 19)

The formula is correct?

Fsensor = root(2) / [2 * pi * root(Lsensor * Ctotal)]

This is not?

Fsensor = 1 / [2 * pi * root(Lsensor * Ctotal)]

------------------------------------

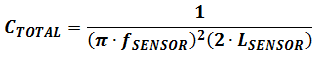

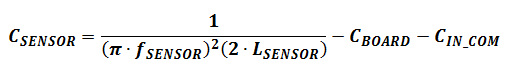

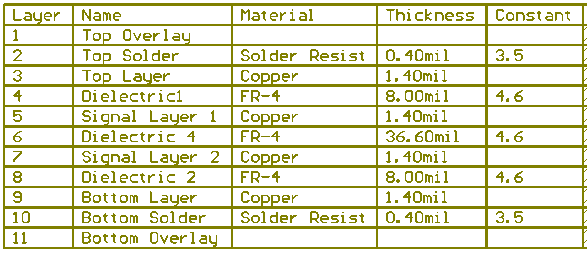

Q2) 9.1.1.2 Sensor Design Procedure (Page 20)

The formula is correct?

Csensor = {1 / [(pi * Fsensor)^2 * (2 * Lsensor)]} - Cboard - Cin_com

This is not?

Csensor = {1 / [(pi * Fsensor)^2 * (4 * Lsensor)]} - Cboard - Cin_com

or

Csensor = {1 / [(2 * pi * Fsensor)^2 * Lsensor]} - Cboard - Cin_com

------------------------------------

Q3) 9.2.3.2 Detailed Design Procedure (Page 25)

If the frequency is 10 Mhz, is that one sample(Fsample) time how long?

------------------------------------

Q4) slyc137 Inductive Sensing Design Calculator Tool (sheet 3 - LDC0851_calc)

at CELL C12

The formula is correct?

=1000/(SQRT(2)*PI()*SQRT(C11*C8))

This is not?

=1000/(2*PI()*SQRT(C11*C8))

------------------------------------

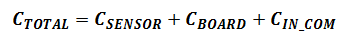

Q5) The LDC0851EVM's PCB infomation?

How lmany space between 1st layer and 2nd layer(x12)

How many space between 2nd layer and 3rd layer(x23)

------------------------------------

Q6) WEBENCH Coil Designer (LDC0851)

At 4: Select Coil Geometry And Other Parameters

In calculating the inductance, How many use layers?

------------------------------------

Q7) WEBENCH Coil Designer (LDC0851) and WEBENCH Coil Designer (Custom)

Two inductance values are similar,

Why are the two calculations differ in sensor frequency?

WEBENCH Coil Designer (LDC0851)

Conditions are as follows:

LC sensor capacitance(C) : 50 pF

Outer diameter of inductor(Dout) : 20 mm

Turns per layer(N) : 10 Turns

Trace width(W) : 0.2 mm

Spacing between traces(S) : 0.2 mm

Copper thickness(t) : 1 oz-Cu

Temperature(T) : 25 C

Space between 1st layer and 2nd layer(x12) : 0.2 mm

Space between 2nd layer and 3rd layer(x23) : 0.6 mm

Space between 3rd layer and 4th layer(x34) : 0.2 mm

WEBENCH Coil Designer (Custom)

Conditions are as follows:

LC sensor capacitance(C) : 50 pF

Outer diameter of inductor(Dout) : 20 mm

Layers(M) : 2 Layer

Turns per layer(N) : 10 Turns

Trace width(W) : 0.2 mm

Spacing between traces(S) : 0.2 mm

Copper thickness(t) : 1 oz-Cu

Temperature(T) : 25 C

Voltage (Oscillation Amplitude)(V) 1.8V

Space between 1st layer and 2nd layer(x12) : 0.2

------------------------------------

Q8) If the two results is correct, question Q7

In the WEBENCH Coil Designer (LDC0851),

Except LC sensor capacitance (C),

How much value addition to the capacitance (C) were using the Cboard, Clcom ?

Thank you

:)