Dear Technical Support Team,

I have some questions about Liquid Level Sensing with the Immersive Straw Approach with FDC.

1.)

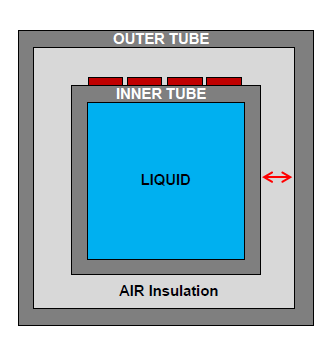

How is the distance between INNER TUBE and OUTER TUBE?

http://www.tij.co.jp/jp/lit/an/snoa934/snoa934.pdf

2.)

Shielded cable length is different between REFERENCE and SENSOR.

REFERENCE shielded cable lenght is longer than SENSOR.

Dose it affect little error of liquid level sensing?

3.)

Which do recommend FDC1004 or FDC2214 for Liquid Level Sensing with the Immersive Straw Approach?

Could you tell me difference between them for this Liquid Level Sensing?

Best Regards,

y.i