Hello,

I am currently working to get my GASEVM board to measure temperature values from 2 PT1000 RTDs (www.digikey.ca/.../1014573). In order to do this I took out the headers on the booster board which were plugged into the RTD1/RTD2 slots. I wired up my RTDs and plugged them in. The setup can be seen below:

Now I have these wired into a Raspberry Pi to transfer the TOF/resistance data over UART. This works well with the TOF data but I am having issues when I try to measure temperature. The following is a picture of the data being transferred to the raspberry pi while doing a temperature measurement:

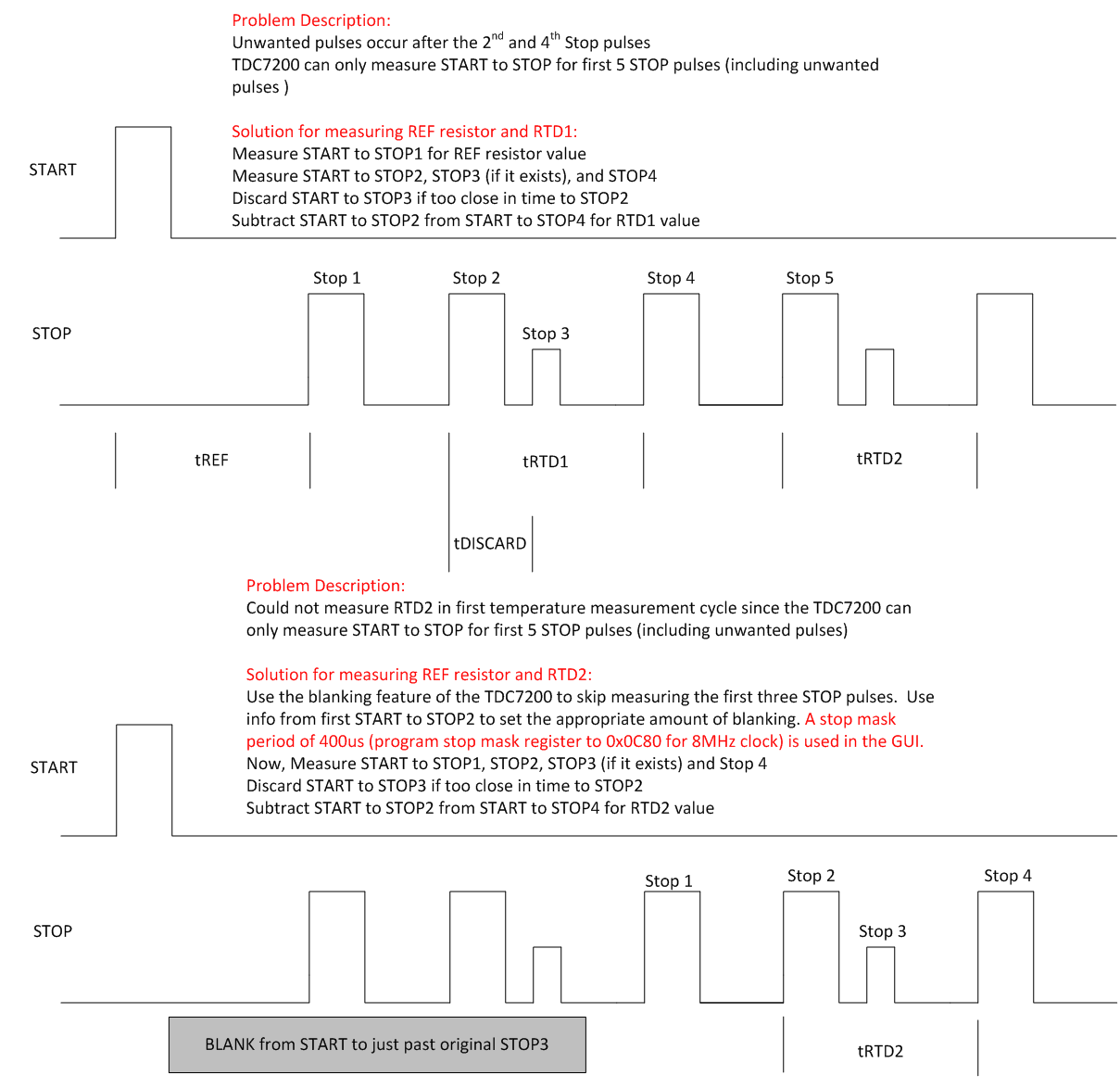

Now I am having two issues with this. The first is obviously the issue of the values "inf" being passed over on every second measurement sequence. I do not know why this is happening. The second issue is with the values I am getting during the other sequences. Using the TDC1000 datasheet I have understood that the resistance of RTD1 can be determined by finding the time interval of start_to_stop[3] - start_to_stop[2], and RTD2 from start_to_stop[5] - start_to_stop[4]. Now the problem I am having is with start_to_stop[2]/[4]. These values are extremely soon after [1]/[3] respectively, and when looking at the stop signals on my oscilloscope I don't know where they are coming from(see below):

as can be seen above, the stop signals which I measure from the oscilloscope give me very reasonable temperature measurements, but the 5 stop signals being provided by the TDC7200 do not correlate with these.

I have read through the application note on RTD measurements, and have noticed it talk about these short timing signals, but I do not know how I can get rid of them. I will continue trying to work through it but any information on this would be very helpful.

note: One possible solution I could think of is to change the firmware to do two separate measurements? the first, taking the first 5 values to find t_rtd1 and then the second one I could blank the first 4 stop signals so that I could determine t_rtd2?

Thanks,

Russell