Hi team,

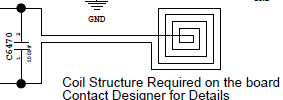

One of my customer is using the LDC1000 as a switch in the server rack application to detect the mechanical switch closing. The coil design is exported from the Webench and it is a square coil similar to what is shown below.

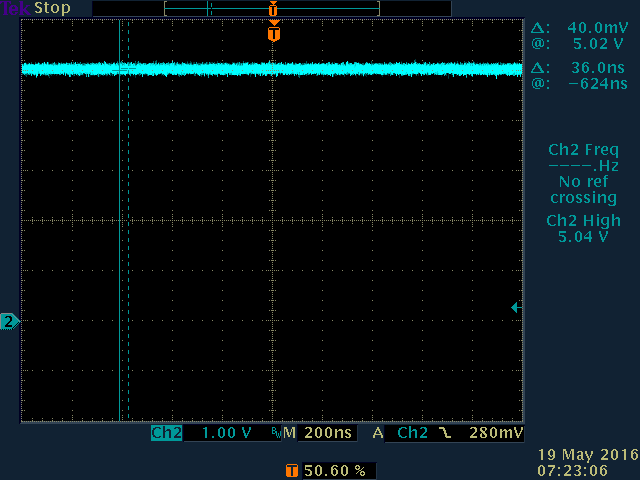

It results in an inductance of 5.8uH. They have used a NP10 470pF capacitor and are able to see the oscillations around 3.75MHz across the tank. When they bring the metal switch close to the coil, we see that the frequency is changing(increases). The Rp value is set to the widest range possible. The capacitor between the CFA and CFB is 22pF.

The issue here is that the proximity count and the Fcount are all zeros. The DRDY bit is always high signifying that the data conversion has not started. When we probe the CFB pin, we see a DC voltage of 5V and CFA pin shows 1V DC. I read in the guide that these pins must show some oscillations; we are unable to see it. The status register 0x20 reads 0xF0.

Can you tell me how to proceed with the debugging? Below is the register writes that they perform.

- Reg 0x1: 0x0E (We tried 0x00 as well)

- Reg 0x2: 0x3F

- Reg 0x4: 0x17

- Reg 0xB: 0x01

- Tried settings Reg 0x03 from 0x01 to 0xFF as well