Hello,

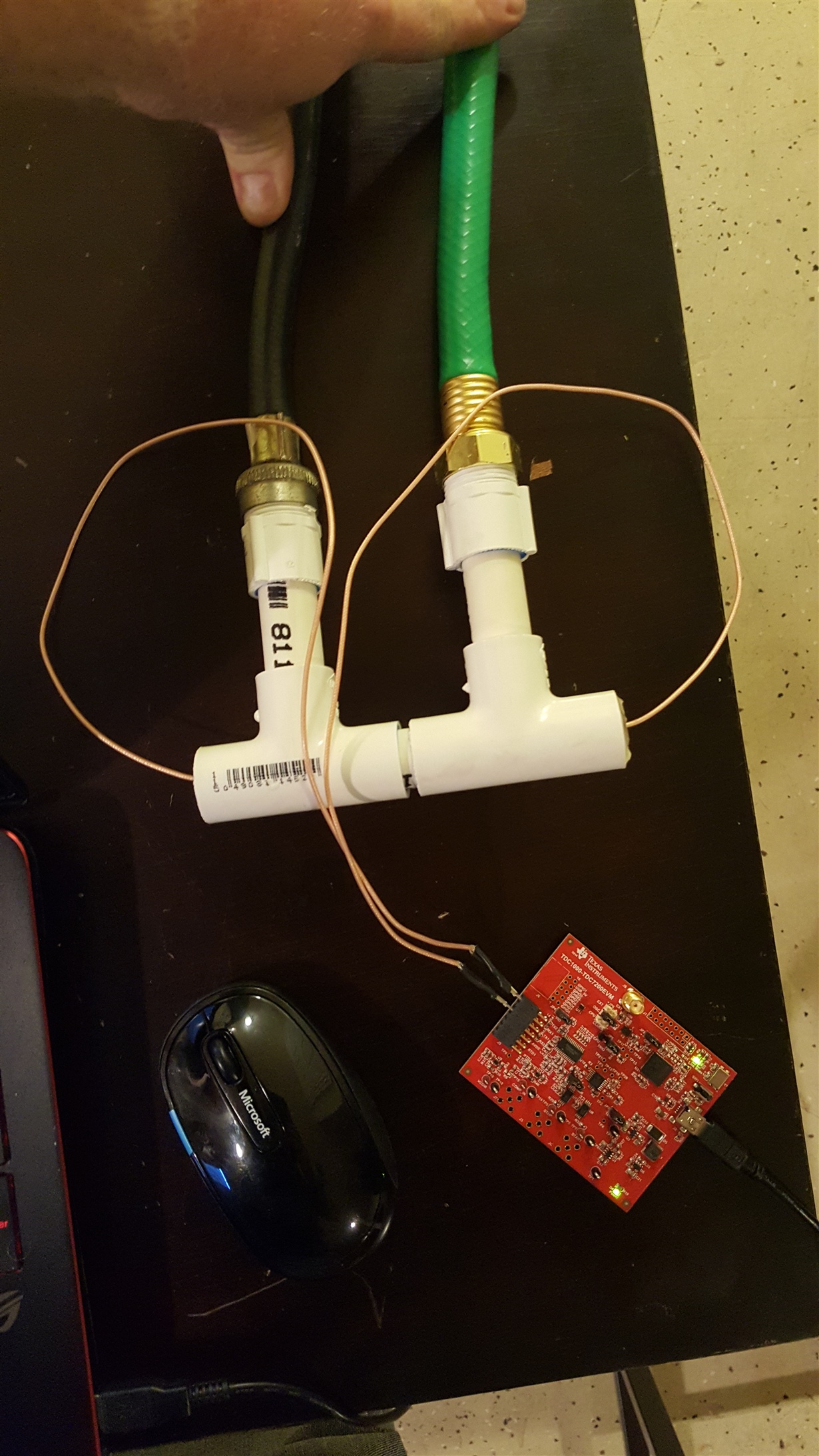

I have gotten an in-line ultra sonic contraption going right now. I have been able to get about 90% accuracy with this test. However, this is not accurate enough for the project I am working on. Even at no flow I am getting about 3 ns TOF when that should be 0 ns. When the flow is running at a constant rate and I run the GUI I am getting about 5 ns deviation in my TOF. Is there something I can do to reduce this deviation in the TOF? I have tried multiple setups for the configuration file and this is about the only one that works for me. Changing any of the averaging values breaks the test and makes the TOF extremely inaccurate ( says 0.3 ns for a 5 gal/min flow rate). Any help would be appreciated! Attached is a photo of the jig I have created and my config file.

Thanks,

TDC1000_Config0 45 TDC1000_Config1 45 TDC1000_Config2 12 TDC1000_Config3 03 TDC1000_Config4 1F TDC1000_TOF-1 02 TDC1000_TOF-0 45 TDC1000_Error_Flags 00 TDC1000_Timeout 1B TDC1000_Clock_Rate 00 TDC1000_Conts_Trigger 01 TDC7200_Config1 02 TDC7200_Config2 40 TDC7200_Interrupt_Status 07 TDC7200_Interrupt_Mask 07 TDC7200_Coarse_Cntr_Ov_H FF TDC7200_Coarse_Cntr_Ov_L FF TDC7200_Clock_Cntr_Ov_H FF TDC7200_Clock_Cntr_Ov_L FF TDC7200_Clock_Cntr_Stop_Mask_H 00 TDC7200_Clock_Cntr_Stop_Mask_L 00 TRIGGER_UPDATE_FREQ 0000 TDC_AVG/STDEV_NUM_ELEMS 0002 SAVE_GRAPH_DATA_TO_FILE 00 FLOW_MODE_SELECT 01 Y-SCALE_CENTER 0000 X-SCALE_RANGE 0032 MEASURE_RTD1 00 SAVE_RESULT_REGR_TO_FILE 00 GRAPH_MULTI_STOPS 00 TDC_SELECT 00 TEMP_RTD_SELECT 00 TEMP_RTD_MODE 01 TEMP_AVG/STDEV_NUM_ELEMS 000A SAVE_TEMP_DATA 00 GRAPH_YMAX_DATA 0000000000011170 GRAPH_YMIN_DATA FFFFFFFFFFFEEE90 TDC1000-HV_DRV_EN1 00 TDC1000-HV_DRV_EN2 00 HV_DRV_EN1_Period 001E HV_DRV_EN2_Period 001E ENABLE_POWER_CYCLE 00 CLK_FREQ_(1-16MHz) 8.000000 CLK_SOURCE_SEL 00 CPU_CLK_FREQ 05 CPU_CLK_EN 00 TDC1000-HV_BST_PWR_EN 00 HV_BST_PWR_EN_Period 0000 FWD2REV_FLOW_DELAY 0000 TDC1000-IMPE_MATCH_EN 00 ENABLE_UART_STREAM 00 ENABLE_MSP430TIMER_TDC 00