Hi,

I am currently working on a keypad for a customer, of which a FDC2112 proximity sensor is sought to be used, in the application note it is mentioned that for a single channel, a copper pour of 20,9 mm x 13,9 mm is to be used for the IC. This raises a couple of questions for me.

- Is this area the bare minimum amount for utilization of said IC?

- Must this area be rectangular?

To expand on the second question, I've been doing some research from Cypress Capsense, it seems that according to their design rule paper, a capacitive coupling can be achieved by make an enclosing ring around the object of interest. For now the product / object will be using FPC (flexible print) and it's therefore neccesarry to avoid large areas of copper beneath this.

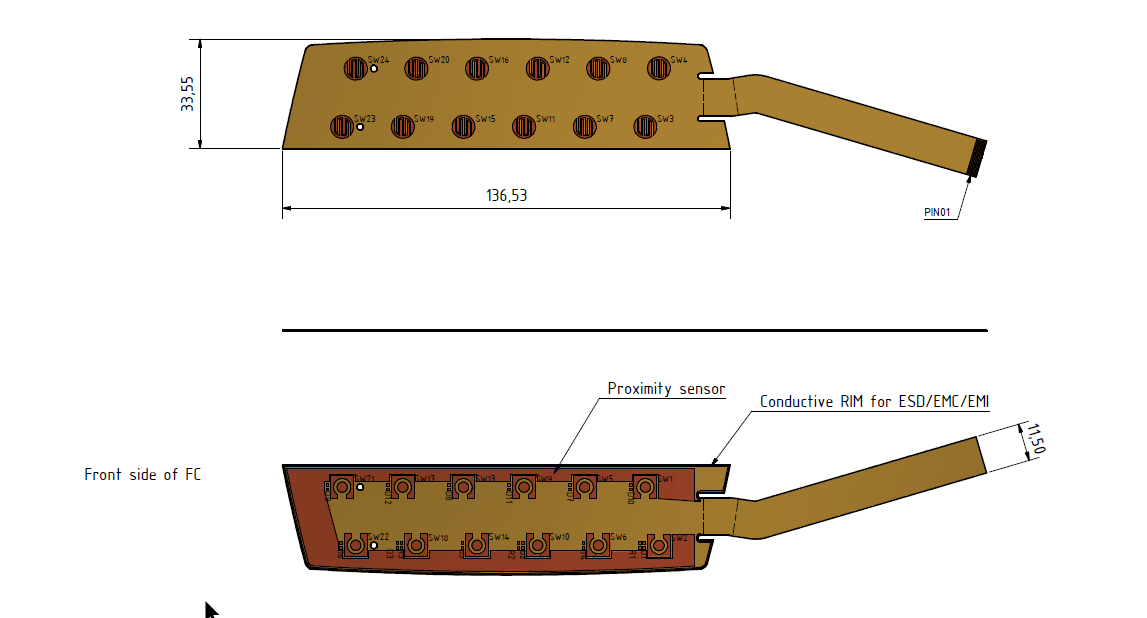

For reference I've attached a picture that *should* document which copper ring I'm mentioning

The darker area that is encompassing the button area is going to be connected at the end of the ZIF cable to create a ring.

Please excuse me if I'm in the wrong forum, I'm merely trying to get some inputs regarding do's and dont's.