Tool/software: Webench

I am trying to measure weight using LDC1614 and the coils suggested by TI (Dout=13.9mm, W=S=0.152mm, 19 turns, 2 layer) with a capacitor of 150pf.

Due to WEBENCH, F=4.5MHz and Rp is around 10k, in which CHx_IDRIVE[15:11]=b01111 (based on datasheet). For this value of DriveCurrent I got strange waveforms in outputs of the coils.

Since the measured frequency was beyond the value WEBENCH gave (F=7.5MHz), I decided to find Rp using the procedure suggested in datasheet(auto calibration) and I found it around 1k and then waveforms seemed to be correct.

To have the highest accuracy I already set RCOUNT=0×FFFF so with Fref=40MHz I need tCONVERSION=26mS which second waveform fulfills the condition.

Now the questions are:

- Is the way I am setting values correct?

- Why this much difference in Rp (Measured and WEBENCH)?

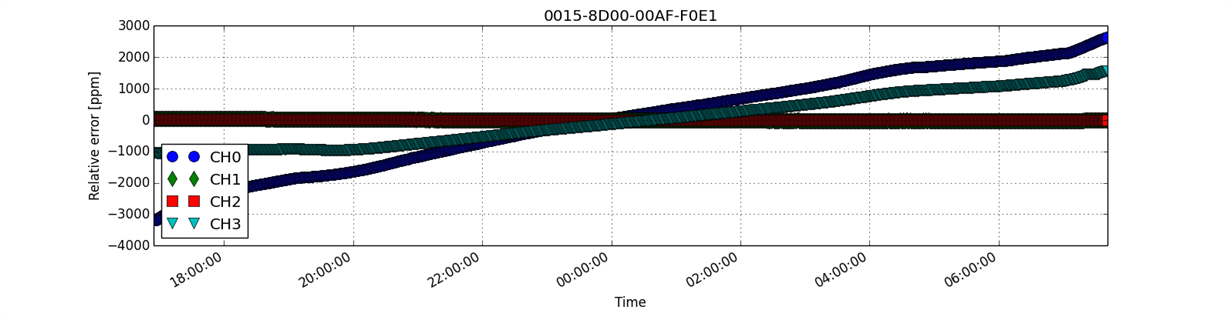

- If the second way I am going is correct: when I measure an actual weight, it is not working properly. First it stabilizes to a point then keeps adding up/decreasing down in every one/two measuring cycle in case I put a weight or take up a weight, respectively(ex: I put 100grms after a few cycles it reaches to say 110grms then keeps adding up by 1grm in every one/two cycle. And when I take 50grms of it up, it stabilizes around say 55grms and then starts decreasing down by 1grm in every one/two cycles). However when CHx_IDRIVE[15:11]=b01111 (strange waveforms in coils output), with the same coding, after stabilization, it just fluctuates around a certain point. What can be the problem? Is it LDC related?

(4 coils are used in continues mode and Data is read using DRDY bit).

Thanks in advance

Michael