Dear Specialists,

My customer is designed and evaluating HDC1080 circuit.

The humidity is higher over 20% than reference humidity meter(Sato Keiryoki Mfg. Co., Ltd SK-110 type1).

They are appeared more than 10% of the total 100pcs.

Temperature value corresponds closely.

What reasons are considered.

Is an additional calibration needed?

Could you please confirm program flow listed below.

---question 1 <programing condition> Is there any problem or not?

(1) Configuration Resister Description(0x02)

(2) wait for over 20msec

(3) address pointer set 0x00

(4) wait for over 20msec

(5) read temperature data

(6) wait for 20msec

(7) address pointer set 0x01

(8) wait for 20msec

(9) read humidity data

---question 2

When data=0x020, data output 14bit

It also output lower 8bit in spite of not 0x00. Is it correct?

Or does it has to be ignored by host CPU?

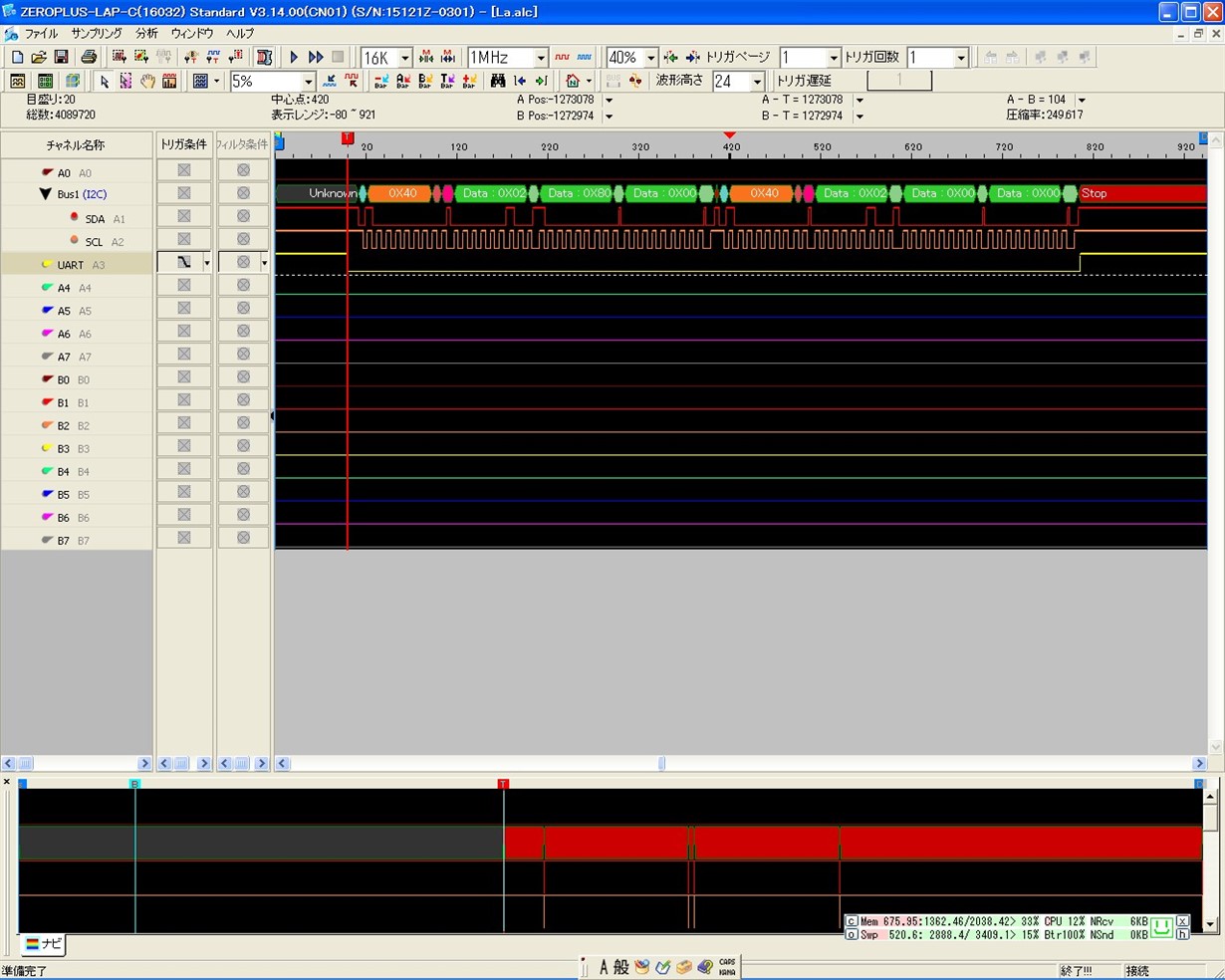

---question3

Could you please see attached image.

It is initial setting of I2C data.

It can be seen 2 times command writing and ACK response.

Is there any problem?

---

I appreciate your great help in advance.

Best regards,

Shinichi