hi dear supporting team,

customer is using our TDC7201, and want to get confirmation on below questions, thank you very much!

-

They use it test cycling signal with 1start and 5 stop, the cycle of start is 1s, and they need continuous test the gap, and report the value every 1s, so btw each test , should they do “start new measurement setting”? from d/s, it seems needed, while when test the EVK ,we can see the GUI can continuous reporting the result without need additional clicking the panel.

-

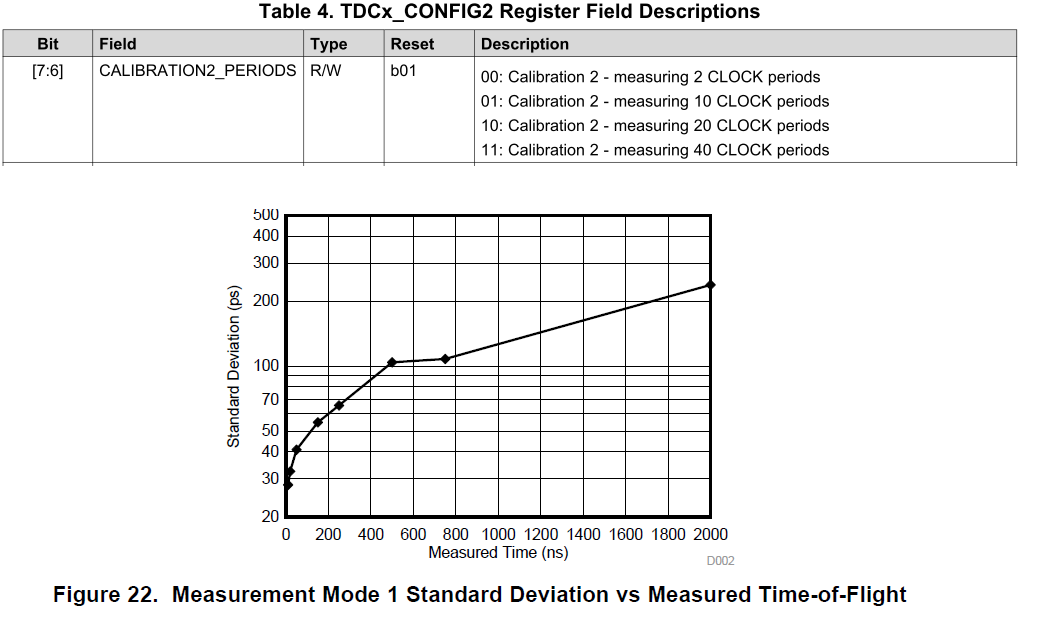

How to set the calibration2_periods to make LSB smaller? From my understanding, the bigger the better, while from fig22, when test higher then 200ns, the error will be bigger than 60ps, is it result with calibrationed or not? so it seems conflict.

3. If customer set these regs to max value, is there any consequence?

-

TDCx_COARSE_CNTR_OVF、TDCx_CLOCK_CNTR_OVF和TDCx_CLOCK_CNTR_STOP_MASK