Dear Luck,

My customer wanted to connect the output from sensor to load of 200 mA.

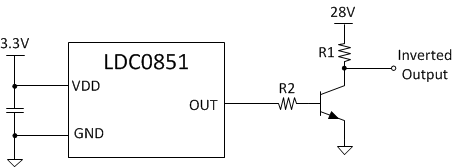

We tried the scheme as attached.

We found as we connect NPN transistor base to the LDC0851 output ,LDC0851 with PNP.pdfthe level for sensing is not flipping.

Please provide inputs how to drive load from LDC0851.

Regards

Seema Joshi