Part Number: TDC1000-TDC7200EVM

Challenge

Measure level from top of a glass bulb, metal sight gauge, or plastic reservoir. The glass is ~5 mm thick, the metal is ~1 cm thick with some depth variance (see "mounted sensors" photos below), and the plastic is ~2 mm thick. The sensor cannot be exposed to the liquid i.e. on the inside of the container.

Problem

While I have successfully set up the TDC1000-TDC7200EVM with an oscilloscope to measure level from the bottom of a glass cylinder, I cannot get any echo signal to register when I try measuring through air from the top of the "tank".

Attempts to solve problem

Transducers used:

- 10 mm 215 KHz SMD10T2R111WL

- 15 mm 1 MHz SMD15T21R111WL

- Gas flow 200 KHz SMFM20F200HG

Mounted sensors:

I have followed the Using Ultrasonic Sensing to Monitor Level in Tanks document and mounted the 10 mm and 15 mm piezo transducers on the top of each "tank" with the proper adhesive.

I have read through (and tried to replicate as best I can) Matthew's post regarding short distance measurements through air. Unfortunately, I have been unable to tweak the register setting to replicate any sort of echo--I'm assuming because I don't have the GASEVM.

Setup with transducer #3:

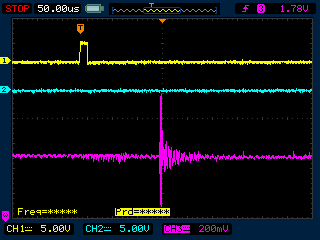

Instead, I get an output that looks like this:

Any help, suggestions, or direction would be greatly appreciated. Thank you.