hello, I have some questions about LDC1612 that I need to ask.

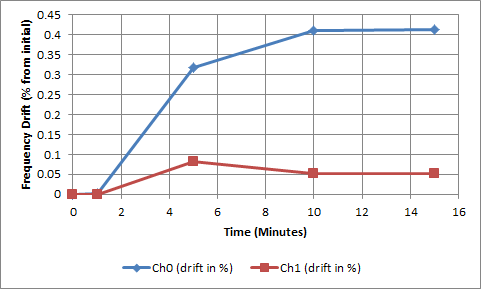

I am using ldc1612 with external inductance, read the value of the recount register after booting, this value has been in an upward state until twenty-thirty minutes before it is stabilized near a value.

why is it ?