Other Parts Discussed in Thread: LDC1612

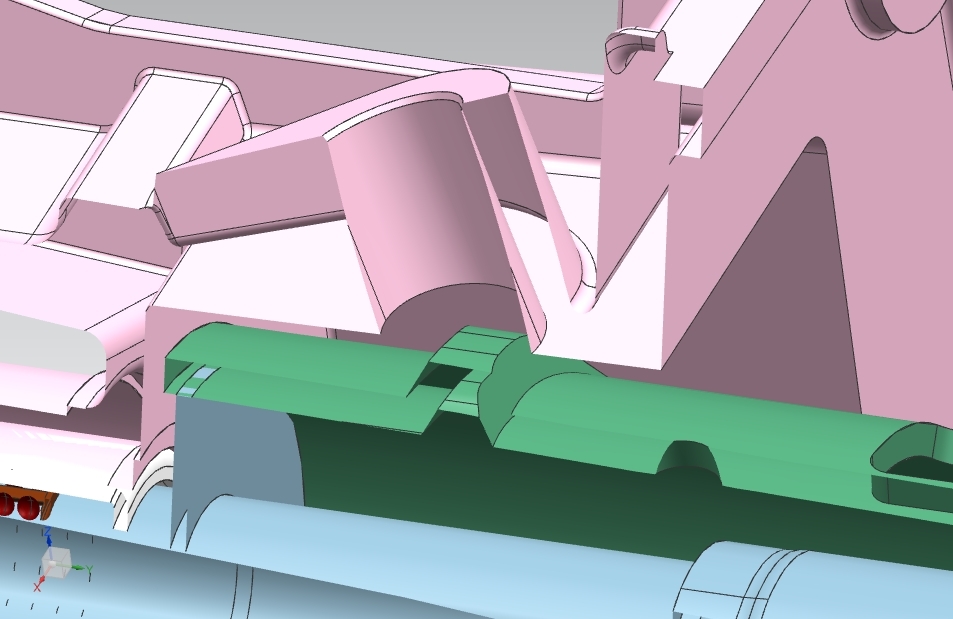

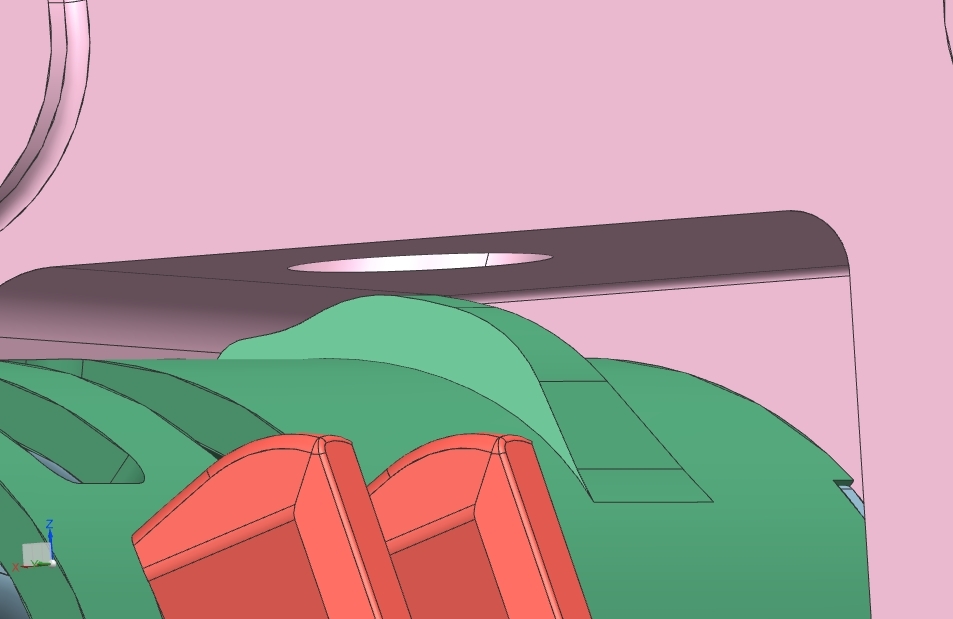

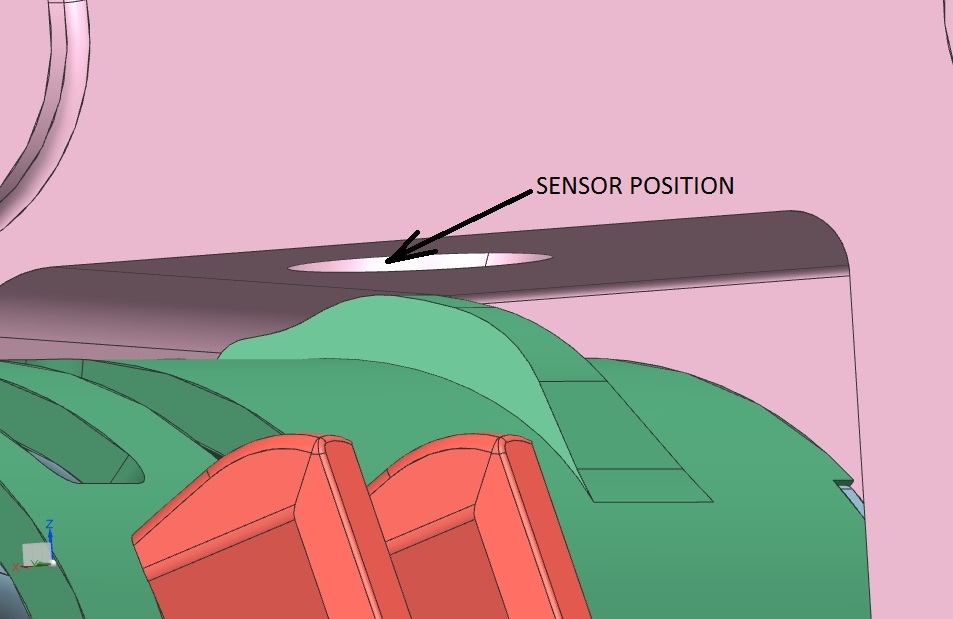

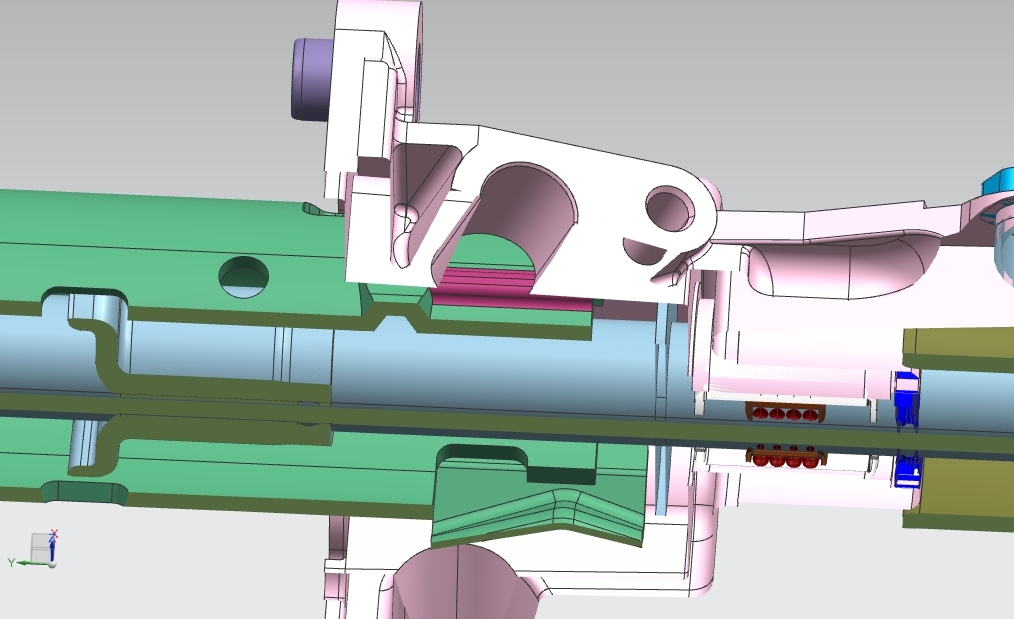

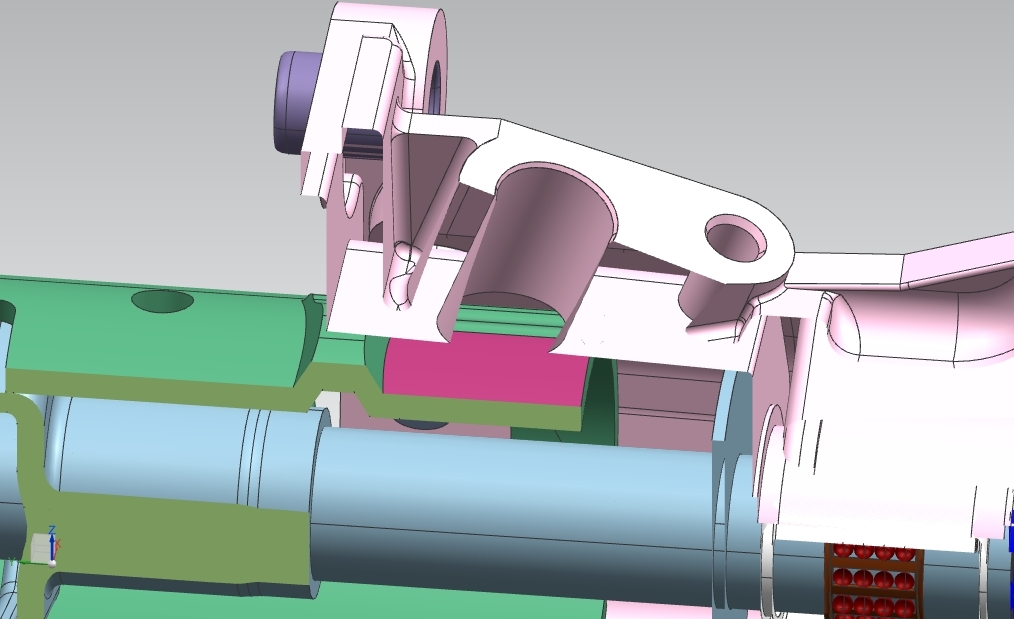

I need to sense the stainless steel target in my project, which i am doing with LDC1312. The target is is gear position sensing

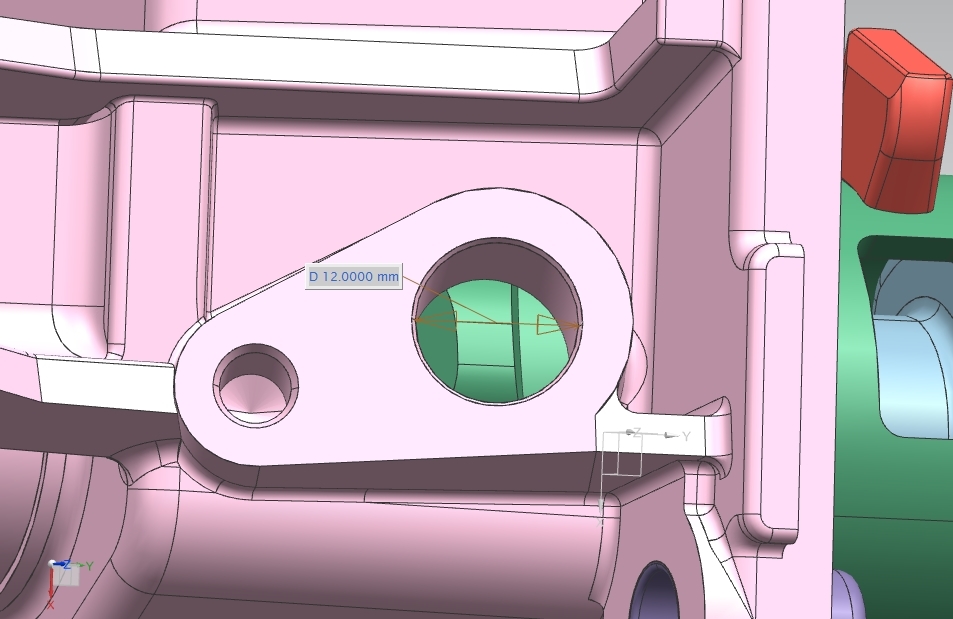

which has three gears and i need to sense three positions. There is a 12mm hole through which i need to sense the movement on

the other side as the gear moves the amount of metal in front of the hole changes which will reduce the distance between target and

the hole. I am attaching the images for reference. The whole material is of stainless steel so i want to avoid the interference caused by

material in pink and want to sense only the green colored material.

Please tell me what configuration is necessary to calculate the count in register 0x00. Also i need a difference in count when the steel

is more and when it is less.

Regards

Sarang