Other Parts Discussed in Thread: IWR1443, TIDEP-0091

Dear All,

I have IWR1443 EVM and DevPack EVM.

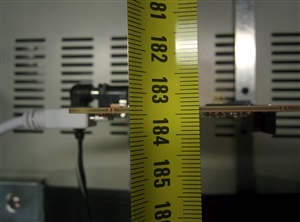

I 'm very interested in the Fluid level application of the radar and it seems that works quite well.

However, currently the information about the level is shown only by using web page https://dev.ti.com/gallery/view/4768107/mmWave_Fluid_Level_Transmitter_1_0_0/

My questions are:

1) Can I have the info about the level in mm available outside the board somewhere in a standard protocol?

2) (this questions is a little bit confused because i'm not an expert in TI devices)

Can I use some tool (I think Radar Studio is the more suitable one) for configuring the antennas, the transmitted signals, received signals, ect...?

3) This device should work in a low-power application. How can I turn it on/off or in sleep mode and send immediately the level when interrupted?

Sorry again, but I'm more familiar with microcontrollers, where everything is easy and immediate. Here, I found some difficulties.

Many thanks,

Davide