Hello,

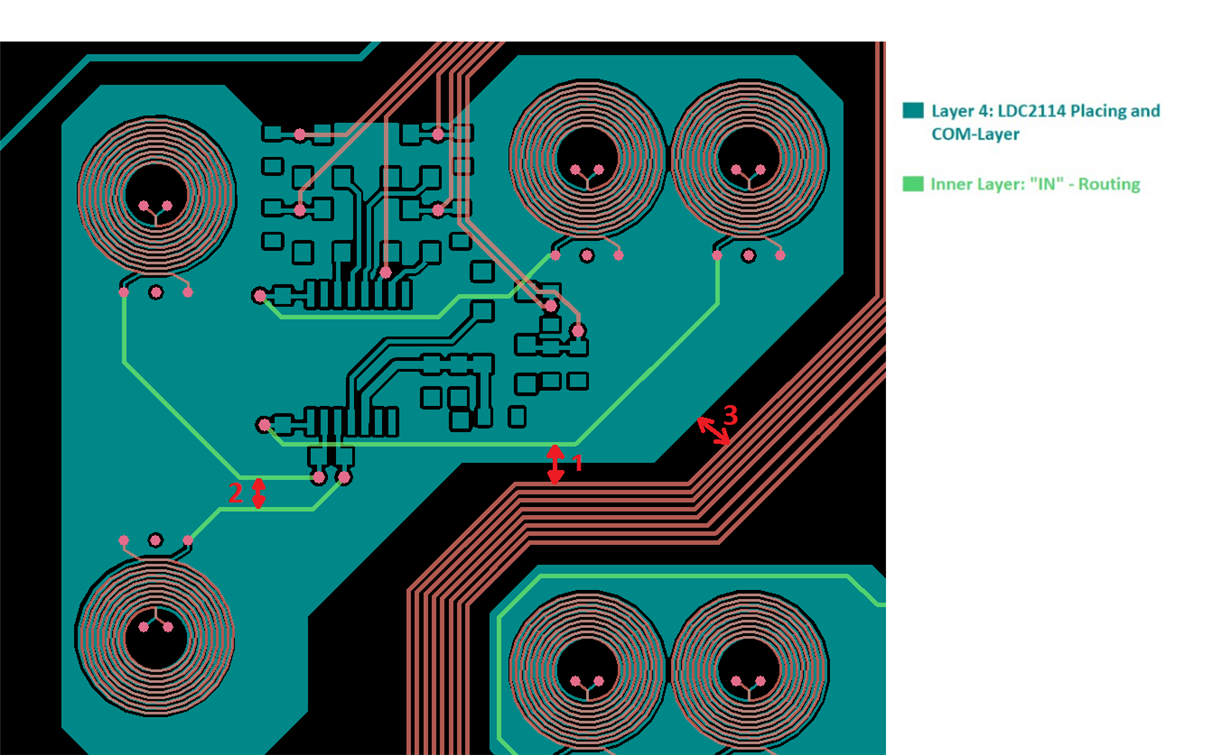

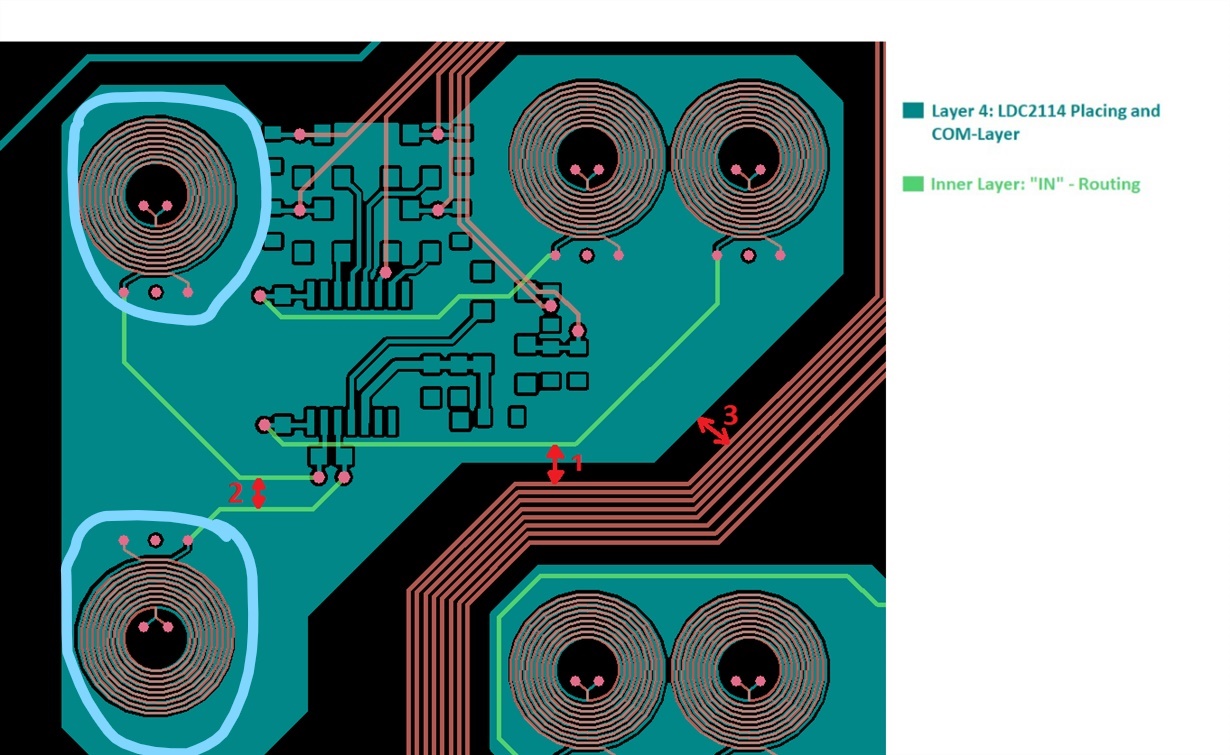

implementing LDC2114 we have some quesion about routing distances, please see the picture below:

1.) What should be the minimal distance between IN-traces and other signals (GPIO, I2C, Power etc)

2.) What should be the minimal distance between IN-traces and other IN-traces?

3.) What should be the minimal distance between COM-plane and other signals(GPIO, I2C, Power etc)

Thank you very much and kind regards,

Clemens