Other Parts Discussed in Thread: LDC1612

Hello Everyone,

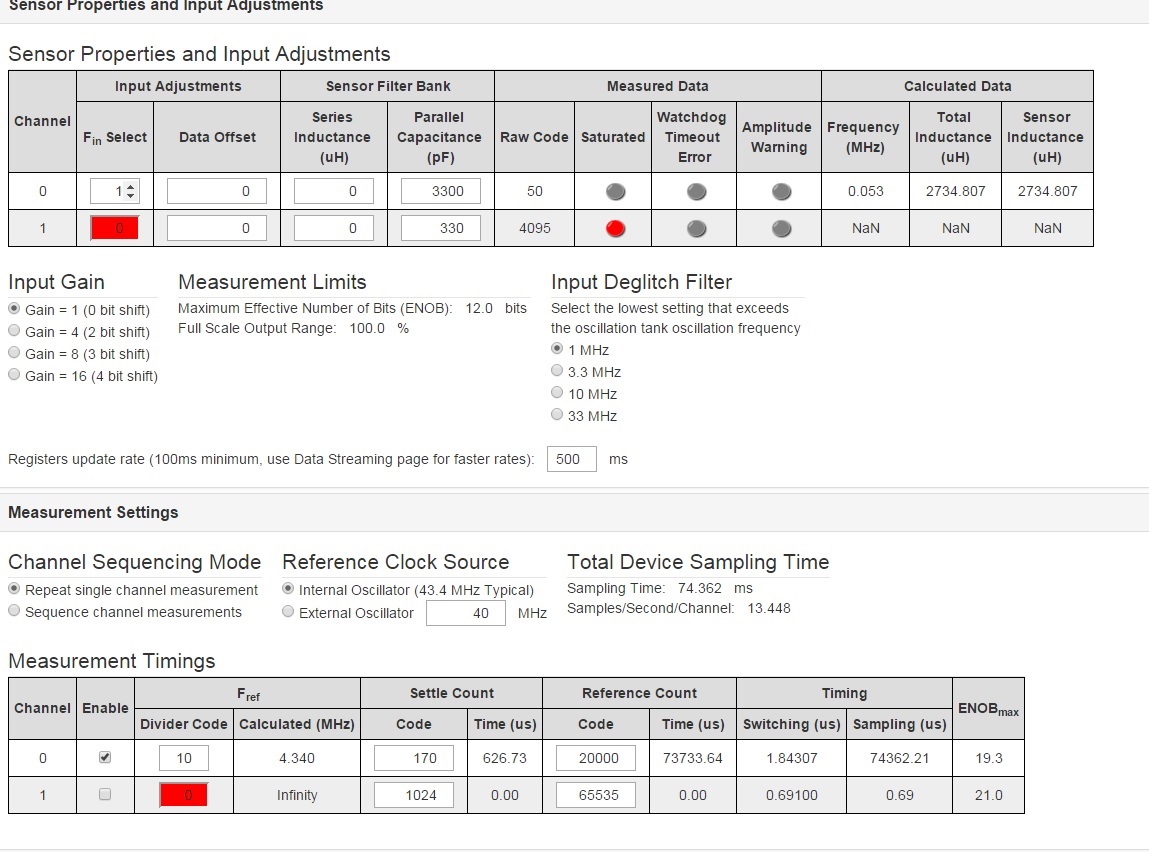

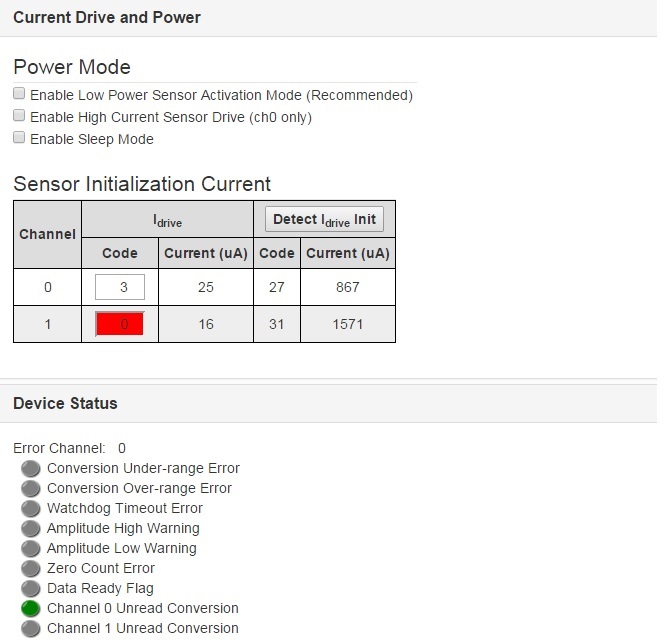

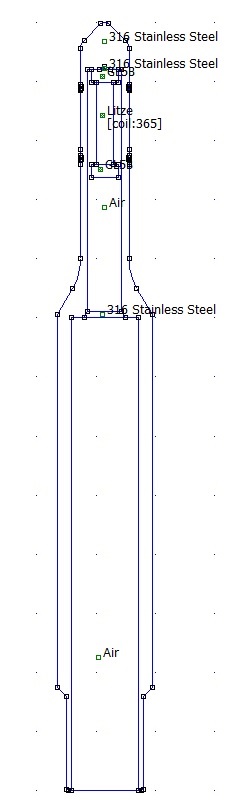

I have and inductor with L = 2,2mH and the capacitor to create the oscilation frequency is C = 3,3nF. The oscilation frequency is about 58000 KHz. I´m using the LDC1312 to get the presence of the target. When I place the target around the inductor, instead of, the frequency increase ie is decreasing. Ii this an abnormal behavior in lower frequencies? The configuration in Sensing Solutions EVM GUI is: