Other Parts Discussed in Thread: MSP430FR2000, DRV5012

Dear all,

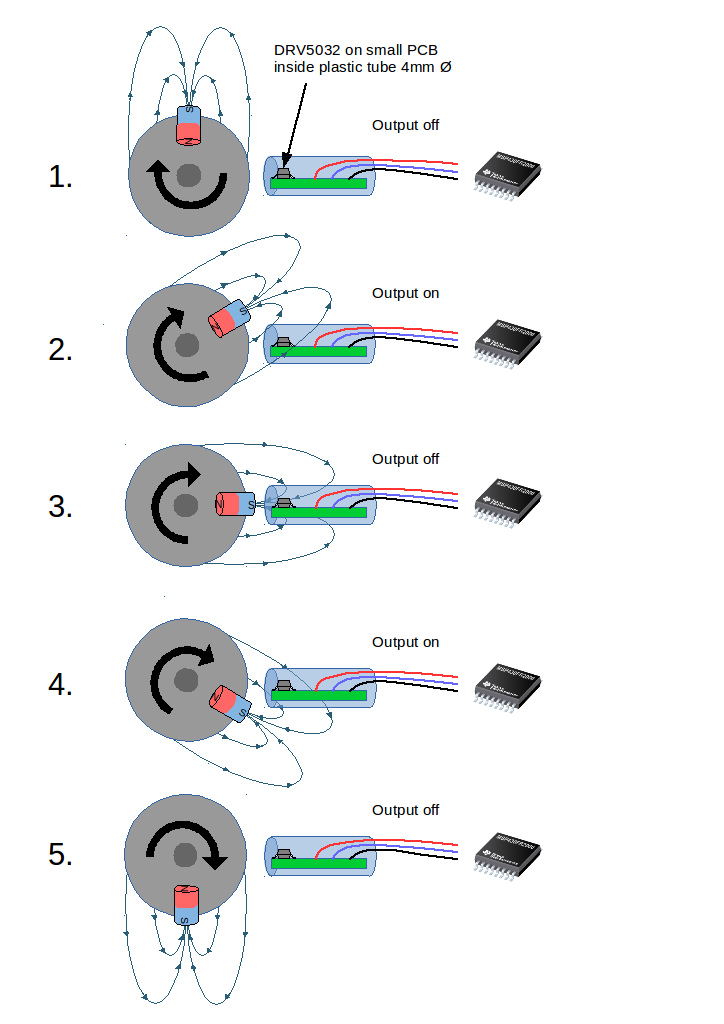

we are looking for a solution to count the number of rotations of a rotating axis (< 10Hz) using a battery powered ultra low power solution. (DRV5032 with MSP430FR2000)

On the rotating axis there is a magnetic pin which should trigger the counter. At the moment we are using a reed switch, but we are looking for a more battery saving option.

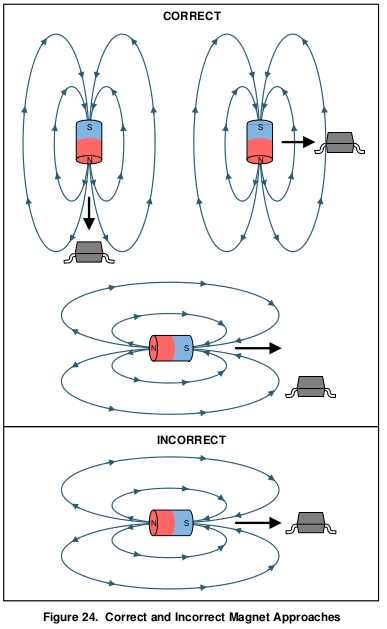

The sensor must be put into a tube or screw casing with max. 4mm diameter, which makes it difficult to arrange sensor and magnet as given in the datasheet:

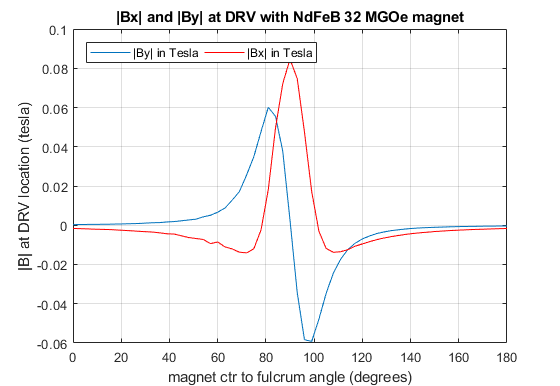

We now need to know if it is possible to to detect the rotation with the DRV5032 with the orientation as given in the below illustration:

With this approach we expect to get two counts with each rotation. Is this a possible and/or recommended way to do it? if not, are there any other suggestions?

Many thanks,

Christian