Other Parts Discussed in Thread: HDC2080

Matt,

It appears we had some information about the critical assembly mentioned in the document.

But we do not know where is the point of error as of now.

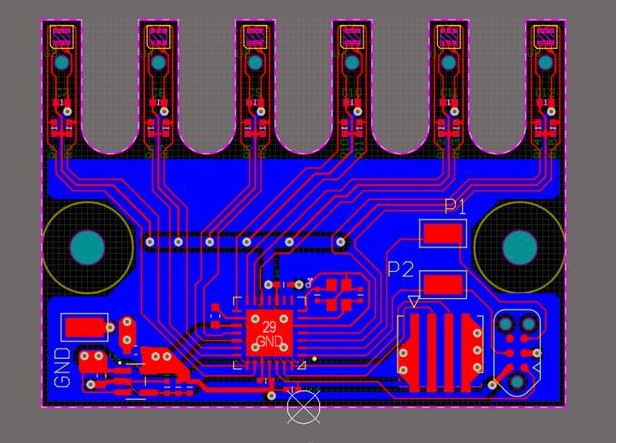

Actually we designed a PCB with 6 HDC2010 sensors to characterize the variation. Fig (1)

Also the few boards we populated was possibility units from different batches of HDC2010.

Attached are the initial scatter plots - we see (hugely) non compliant measured values Fig. (2)

Can this amount of drift be expected from assembly mishap in your experience?

Also - What would you suggest as next step to solve this issue?

Confirm assembly procedures are done well once again ? (we are prepping to re-assembly another set)

Also Is there an evaluation board/kit which we can use to retest & characterize sensor to sensor variation ? May be buy few eval boards and retest?

Please let me know your thoughts.

Prasad

Fig(1) PCB we have used, 3 such PCBs left in free air and such that all devices measure humidity at almost the same instant.

Fig(2): Sensor to sensor variation scatter plots