Part Number: LMT70

Other Parts Discussed in Thread: TMP117

Hello,

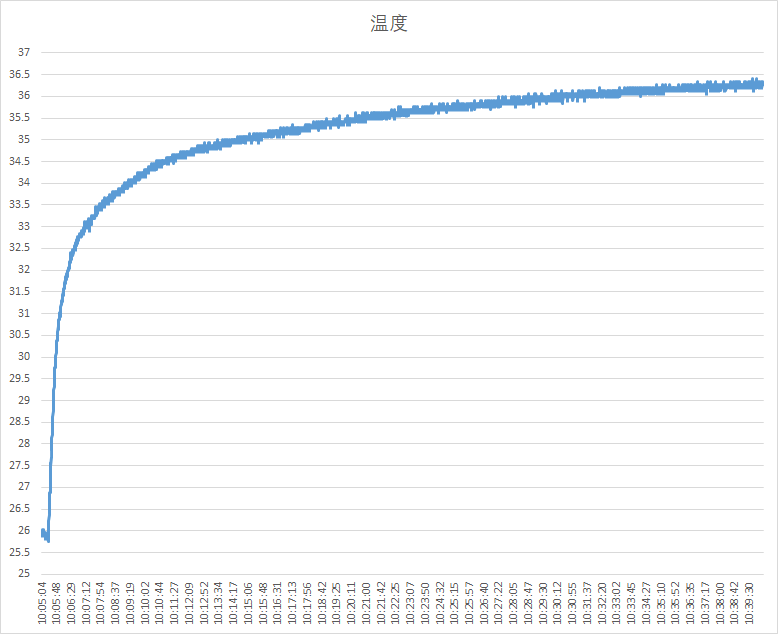

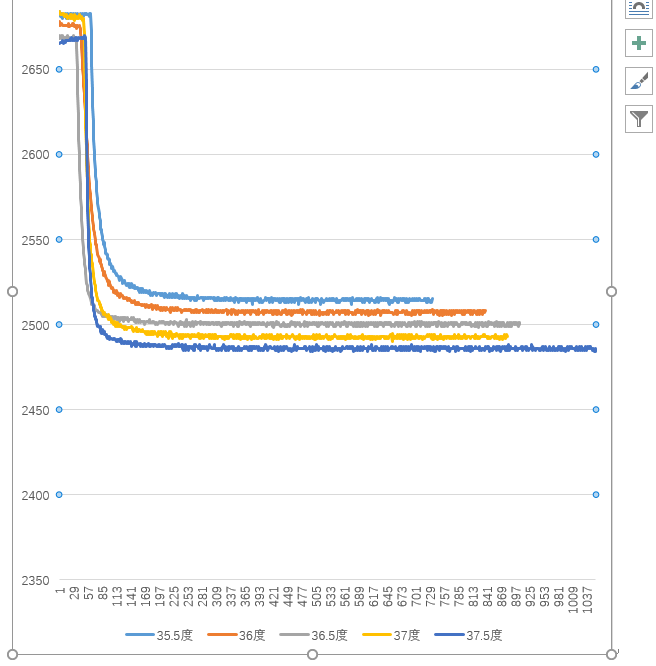

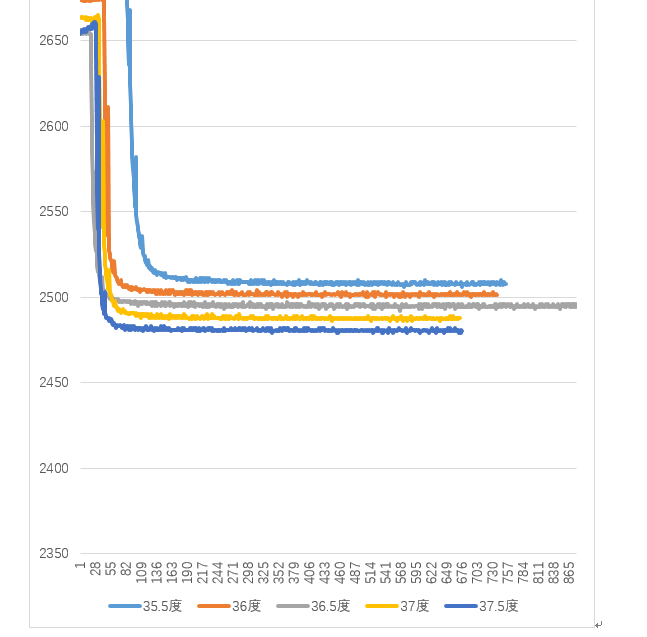

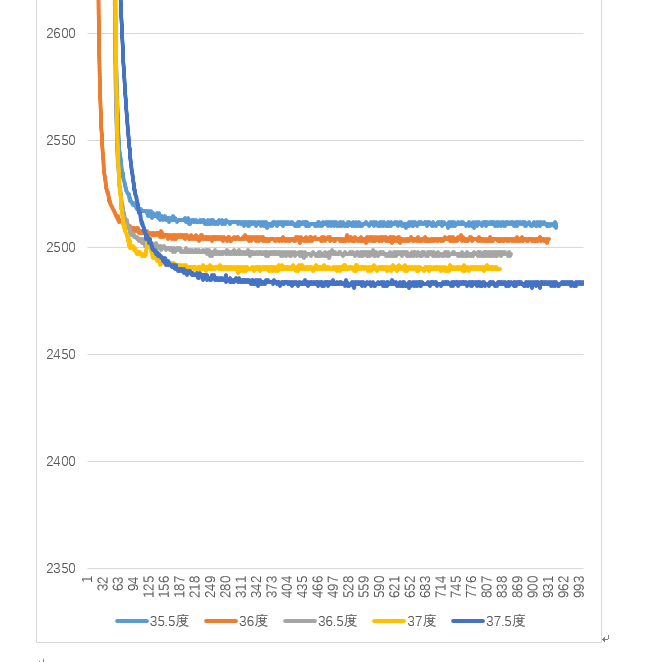

Our customer use LMT70 to measure Skin temperature, but he found that the response time changes slower before after about 33 degree, the whole time need about half an hour to get stable, so he'd like to confirm if it need so long time? Or if we need below 300ns to get stable, how to resolve it ?

Best regards

Kailyn