Dear TI

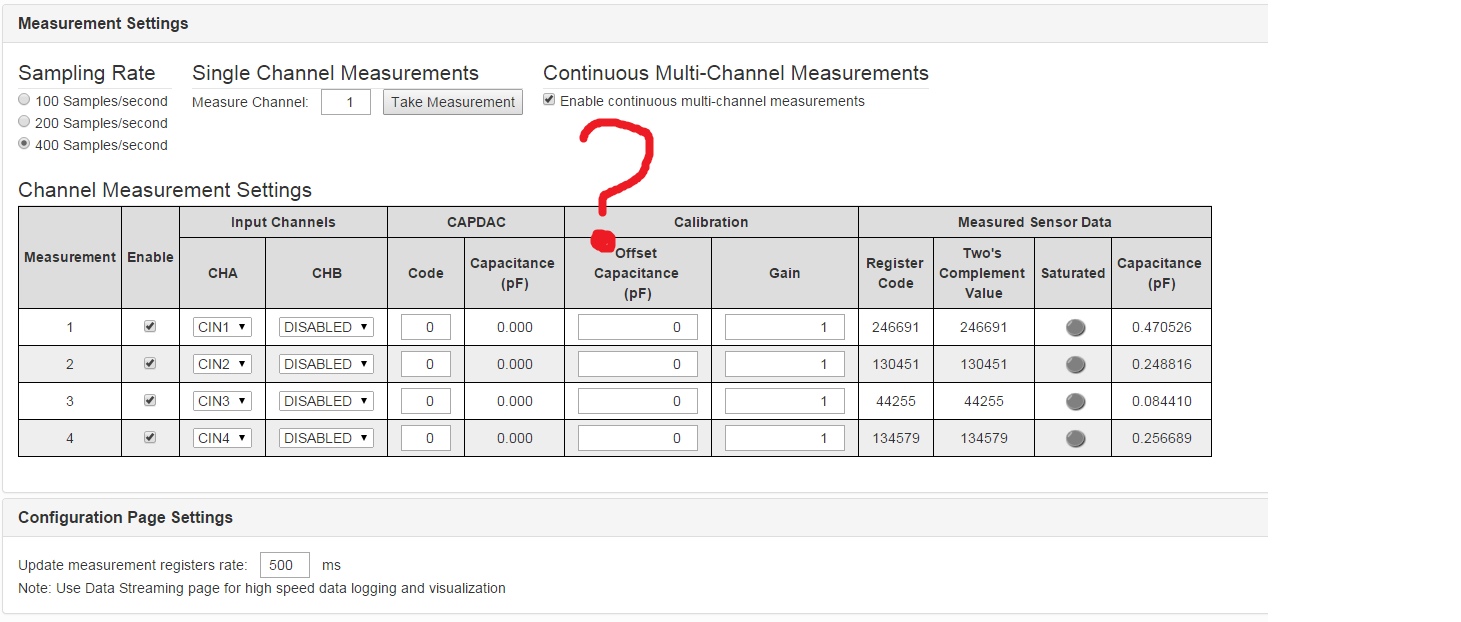

Please help me understand how to use this GUI v1.9.4 , I am stuck here. In the datasheet, it says that starting the measurement configuration i have to set the input channel in GUI and choose what type of measurement (either single-ended or differential). Does this fdc1004 evm consider as differential? If so, what to set in the Channel measurement? What these means CAPDAC, offset capacitance and gain, measured sensor data?

What does delta and standard deviation in statistics mean?

and this?