Hello Hall sensor gurus!

I have this question (and observations) from my customer:

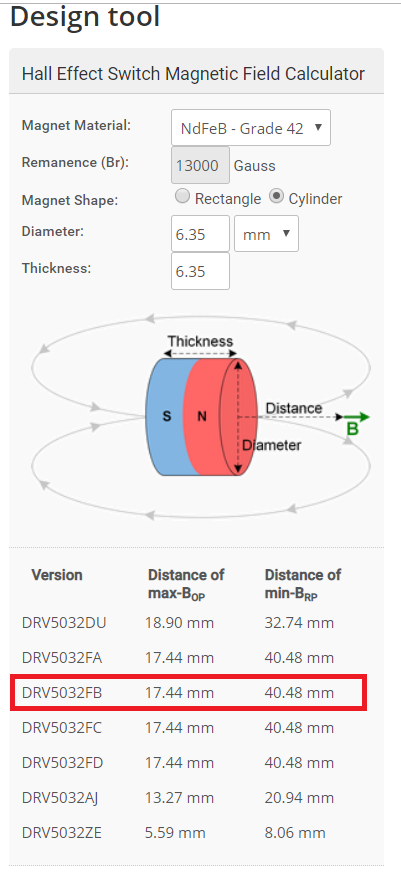

Using DVR5032FB

Using NdFeB Grade 42 Cylinder 6.35mm x 6.35mm (0.25” x 0.25”)

Here is what the design tool says I will get in performance.

Converting this to inches, that’s 0.72” for Bop and 1.59” for Brp

OK, I have a prototype working, and here is what I am getting empirically:

Bop = 0.85”

Brp = 1.05”

Question: The tool tells me I will have hysteresis in the range of 1.22” but I am only seeing hysteresis of 0.2”

That is a huge difference. Can you explain to me why I need to make sure Brp is so far away?

In my design, if I have to go 1.22” away from trigger point to make sure the IC shuts off, it doesn’t work for me.

I need help with this. Please advise.

-------------------------------------------

I did a quick calculation using equation 2, page 16 from the datasheet, and it looks like the customer values line up very nicely with the Typical BOP and BRP values. So, it looks like the measurement was done properly...

Please comment on the Web tool values more and address the customer concerns about the maximum hysteresis value they can expect.

Thanks!