Other Parts Discussed in Thread: MMWAVEICBOOST, UNIFLASH

Dear experts,

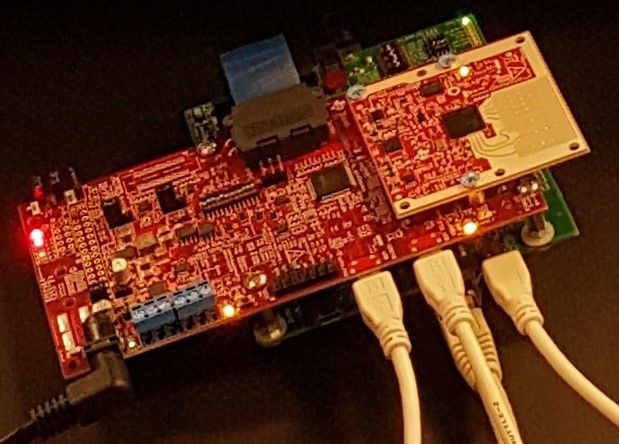

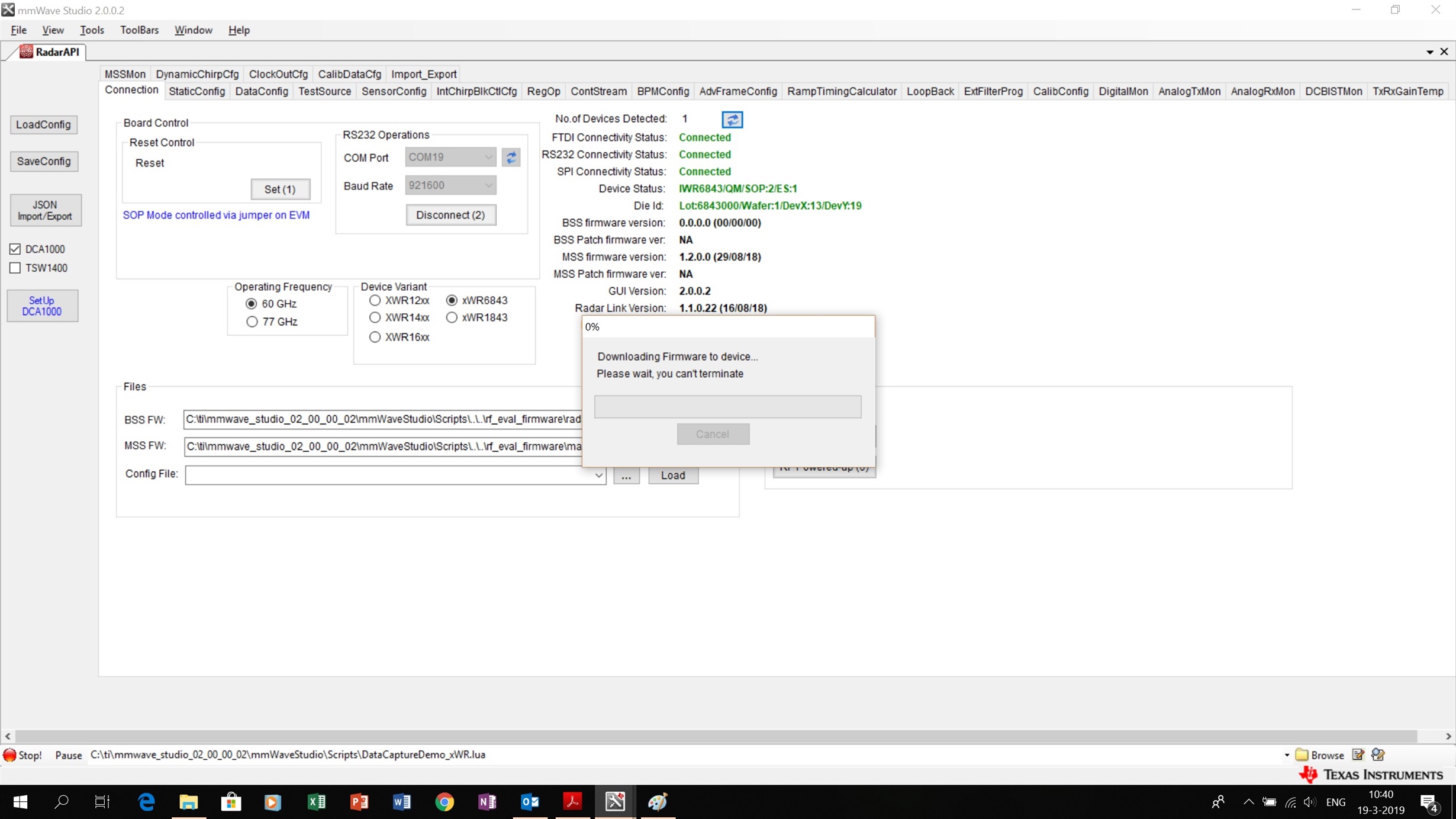

is it safe to connect heat-sinks on the antenna module and the carrier board? The manual (swru546a) recommends to do so, and I did, and the antenna module stopped working on a second day of experiments. The "power good" LED turned off, the radar chip became very hot and died, probably due to electrostatic discharge when I was touching the heatsink. The carrier board remained operational. Now I want to minimize risks setting up a new module. Thanks.

Best regards, Timofey