Other Parts Discussed in Thread: LMP91000

HI

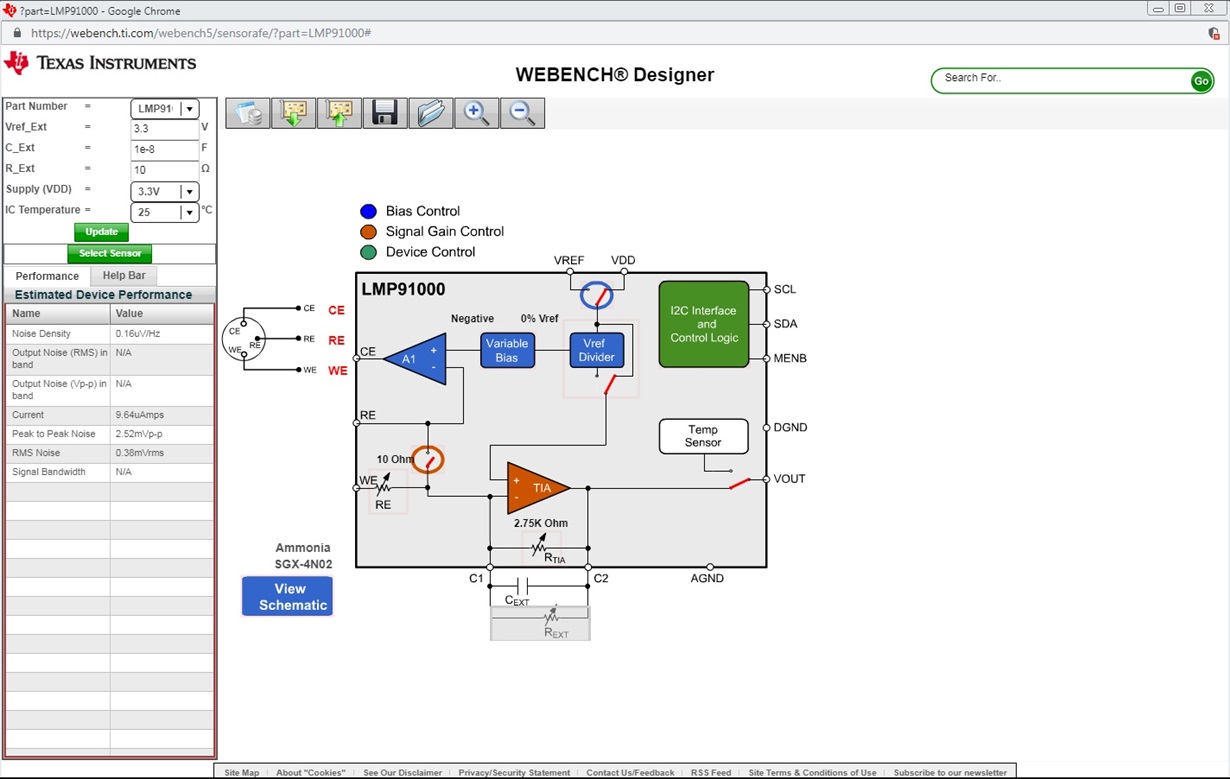

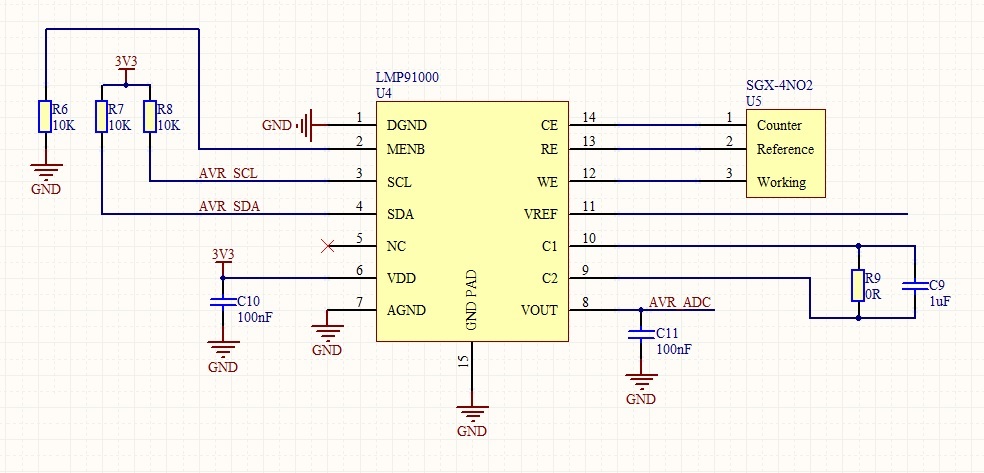

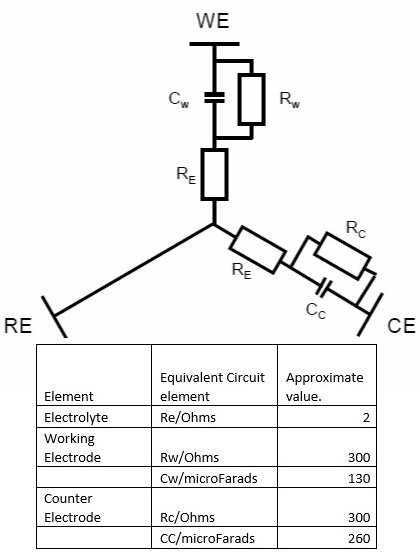

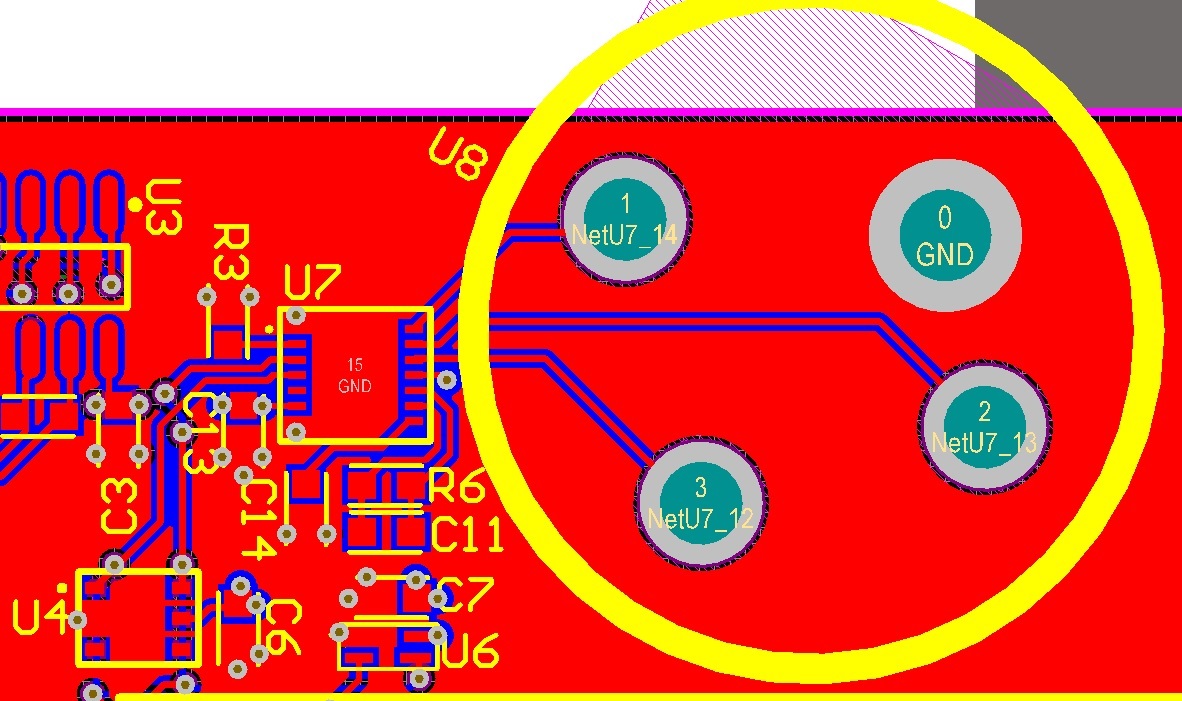

I am very interested in using either LMP91001 or LMP91002 , for the following sensor SGX-4NO2 . The pdf is attached,

Can you please advice me if these sensor device ic will be compatible with this sensor?

What is the difference between LMP91001 and LMP91002 ? or if there is any other device we could consider?

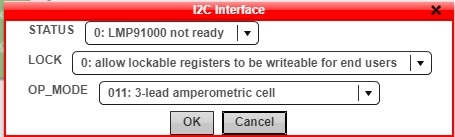

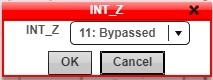

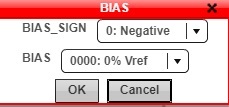

We are looking into a plug and play design for this sensor, so we do not want to spend much time experimenting around as this is not a priority sensor, so please do advice how the device must be configured.

Thank You