Dear Bala and Clancy

1. As you said, using another channel as a reference to rid the temperature drift. In our design, space is limited.

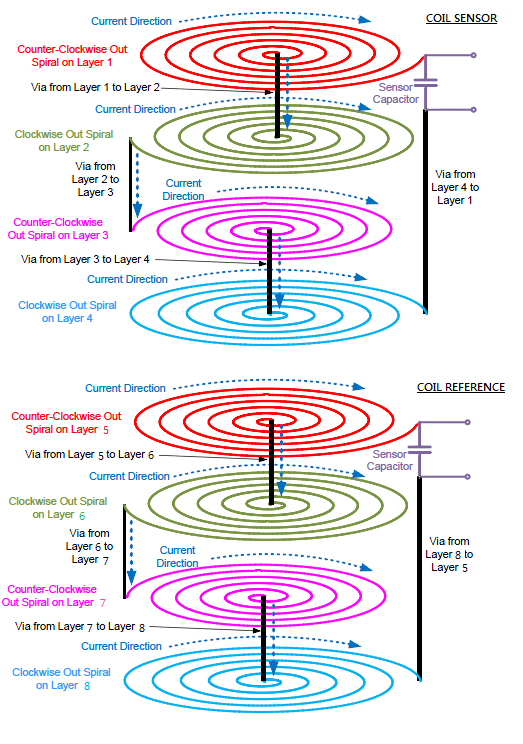

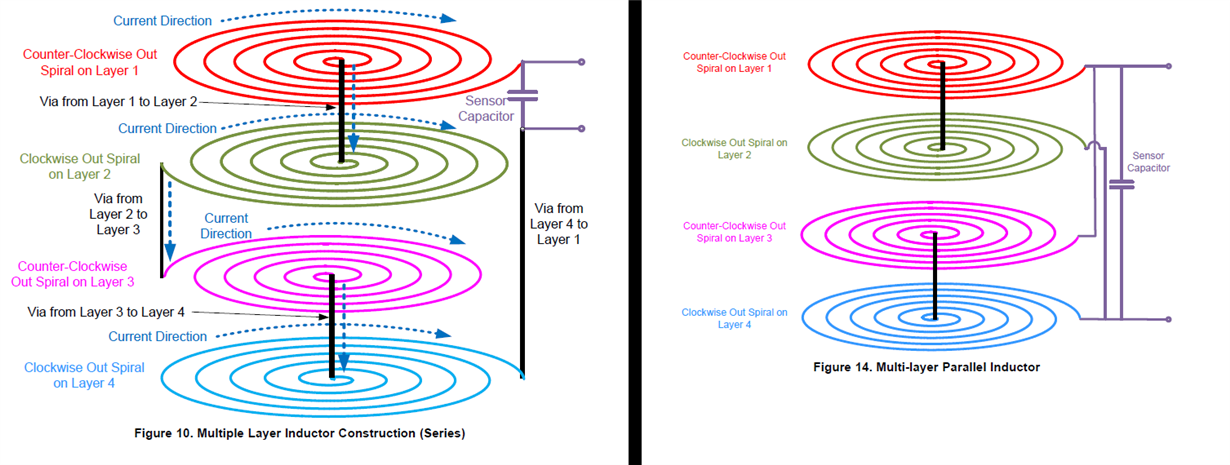

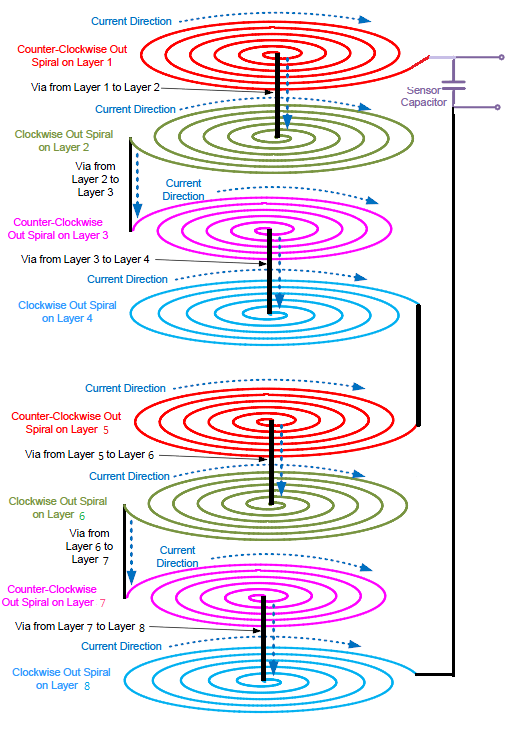

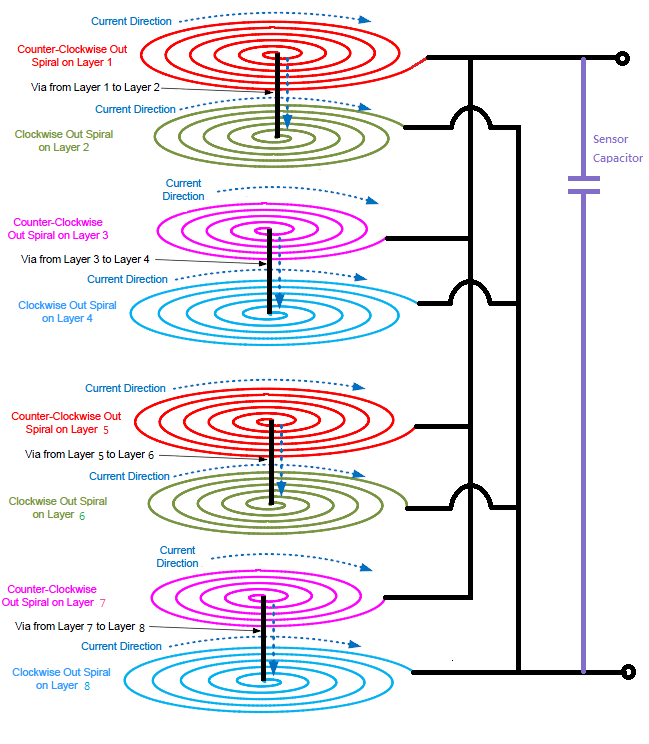

Is it possible to design a coil (a sensor coil and reference coil) in 1 PCB (stacked form) for 2 channels? 1 to 4 layers is for coil sensor and 5 to 8 is for reference coil.

If possible what is the required layer gap between layer 4 and layer 5.

Please see figure below.

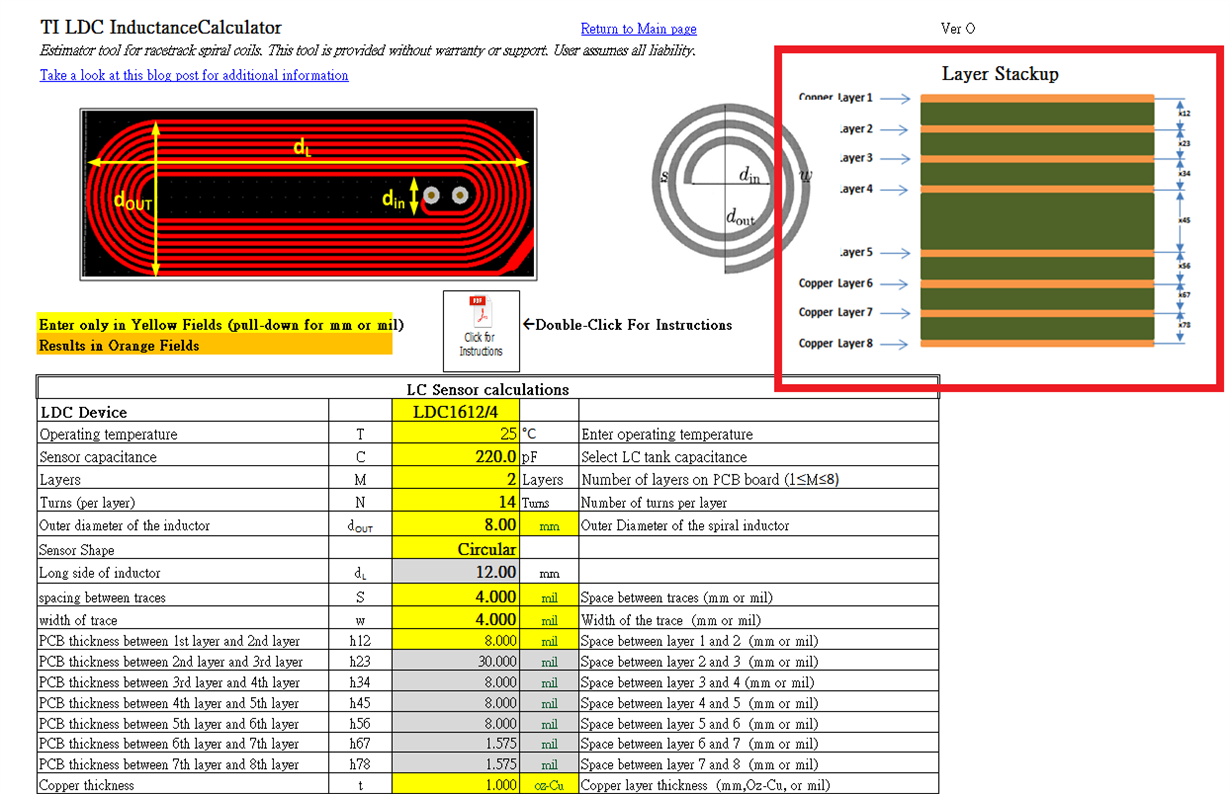

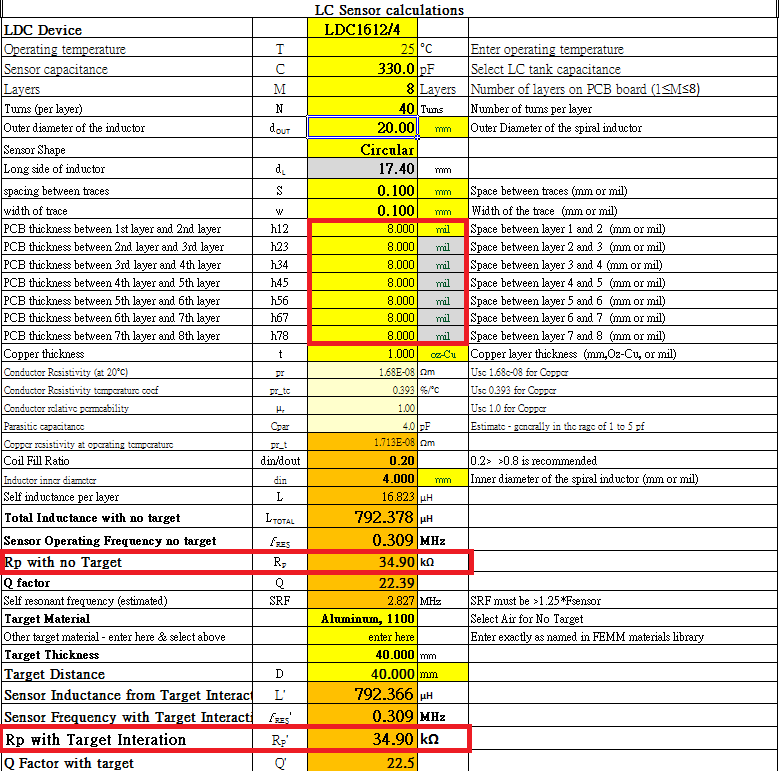

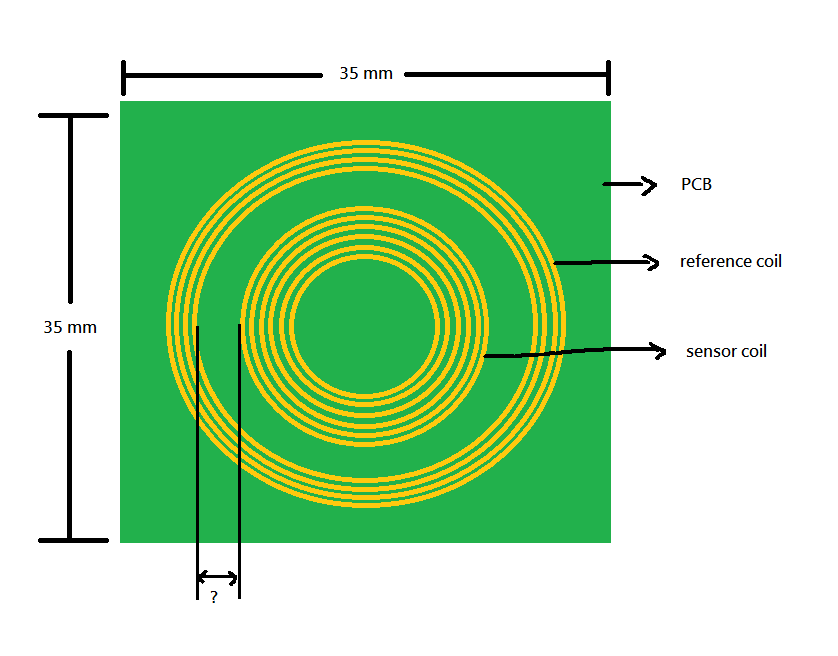

2. In designing coil, is it necessary to input the layer to layer gap value? Figure below is from LDC inductance calculator.

What does it mean under layer stackup, each layer value "x12, x23, x34...."?

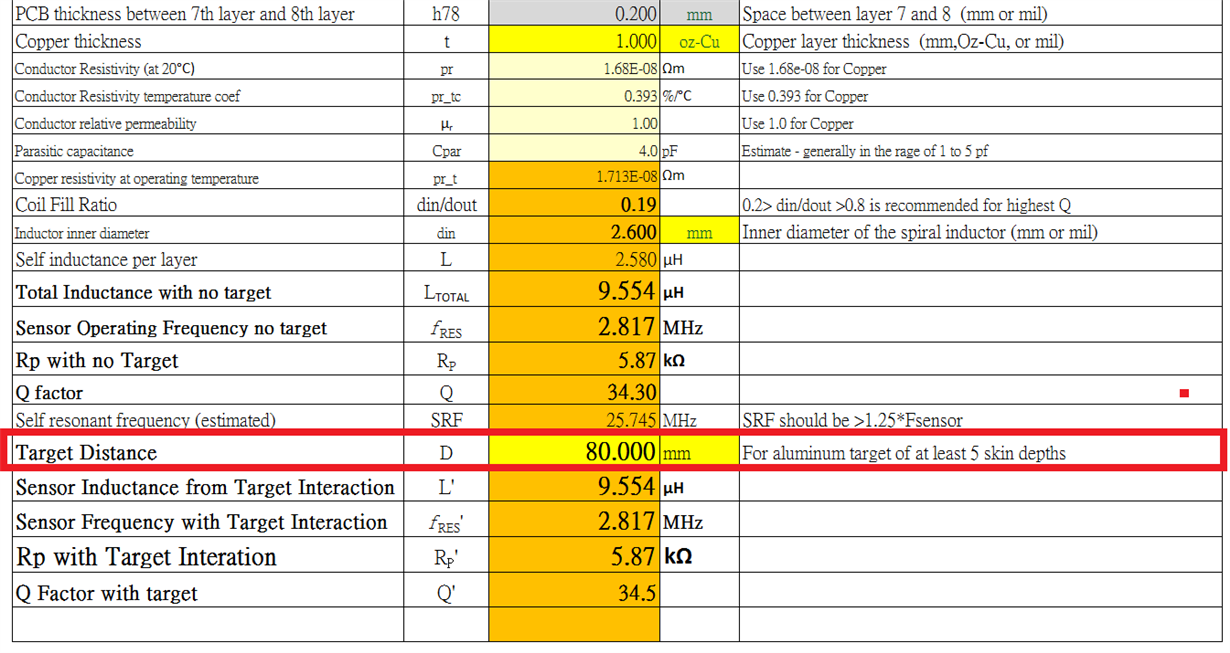

3. In LDC Inductance Calculator, is it possible to set the distance using 2 cm dimension of coil with 8 cm target distance?