Hello TI Team,

I am working with TDC1000 where my goal is to measure ToF using Piezo ceramic transducer 1MHz. I am following snaa270.pdf application report (Using Ultrasonic Sensing to Monitor Level in Tanks) to test that my circuit and sensor is working properly, but no matter how far is my object from the transducer ToF is not changing. That it would be more clear that's what i did:

1) Configured registers for TDC1000 using SPI protocol. Register values can be seen below. (NOTE: I was not using TI GUI. Values was uploaded manually)

CONFIG_0

RAW: 0x44

TX_FREQ_DIV: 8

NUM_TX: 4

CONFIG_1

RAW: 0x41

NUM_AVG: 1

NUM_RX: 1

CONFIG_2

RAW: 0x0

VCOM_SEL: INT

MEAS_MODE: TOF

DAMPING: OFF

CH_SWP: OFF

EXT_CHSEL: OFF

CH_SEL: 1

TOF_MEAS_MODE: 0

CONFIG_3

RAW: 0xC

TEMP_MODE: REF, RTD1, RTD2

TEMP_RTD_SEL: PT1000

TEMP_CLK_DIV: 8

BLANKING: ON

ECHO_QUAL_THLD: -220 mV

CONFIG_4

RAW: 0x5F

RECEIVE_MODE: MULTI ECHO

TRIG_EDGE_POLARITY: RISING

TX_PH_SHIFT_POS: 31

TOF_1

RAW: 0x40

PGA_GAIN: 6 dB

PGA_CTRL: ON

LNA_CTRL: ON

LNA_FB: CAPACITIVE

TIMING_REG[9:8]: 0

TOF_0

RAW: 0x1E

TIMING_REG[9:0]: 30

ERROR_FLAGS

RAW: 0x0

ERR_SIG_WEAK: 0

ERR_NO_SIG: 0

ERR_SIG_HIGH: 0

TIMEOUT

RAW: 0x23

FORCE_SHORT_TOF: OFF

SHORT_TOF_BLANK_PERIOD: 128 x T0 -> 1600.00 us

ECHO_TIMEOUT: ON

TOF_TIMEOUT_CTRL: 1024 x T0 -> 12800.00 us

CLOCK_RATE

RAW: 0x1

CLOCKIN_DIV: 1

AUTOZERO_PERIOD: 128 x T0 -> 1600.00 us

TOF Control: Standard TOF

with blanking

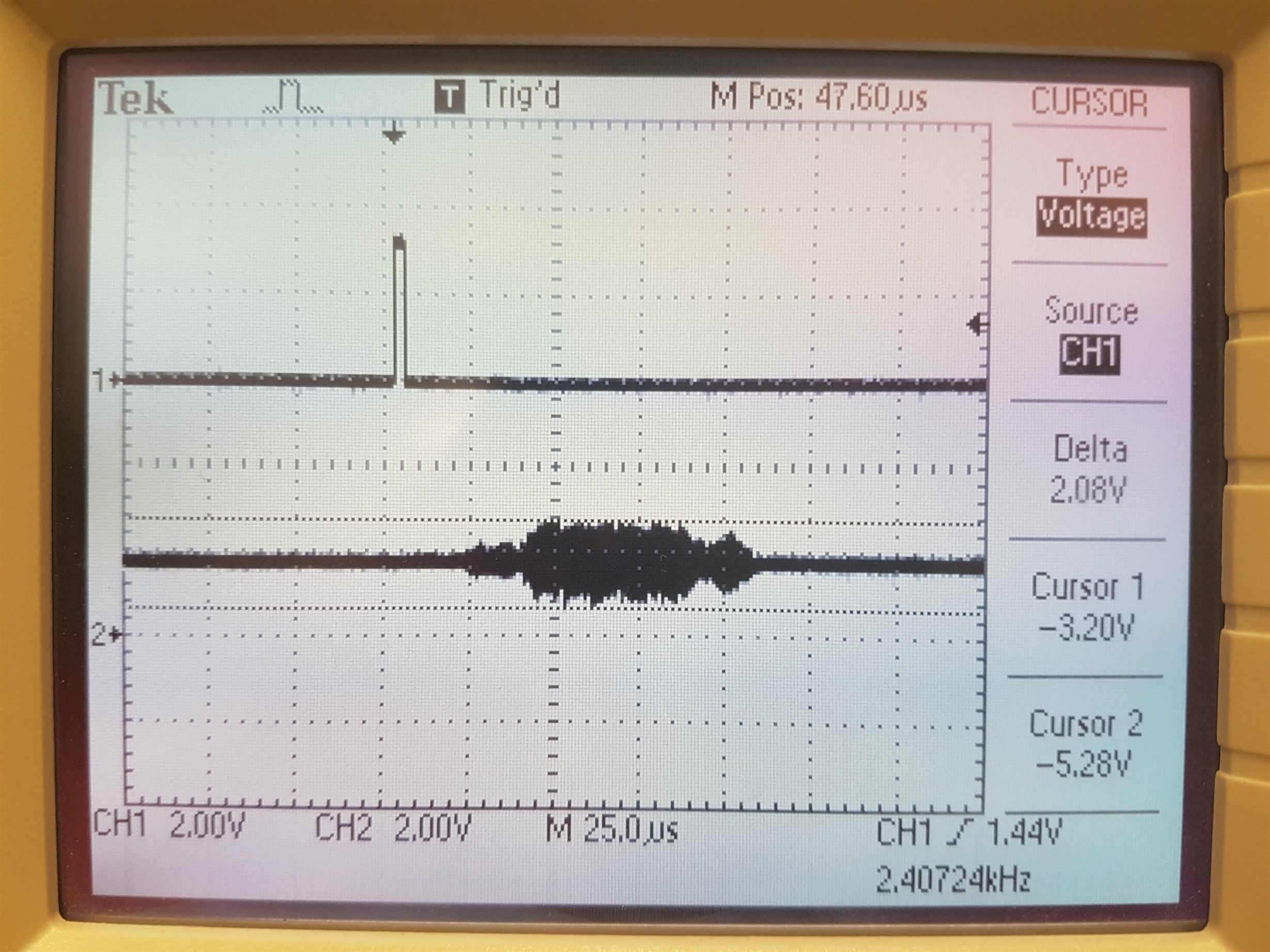

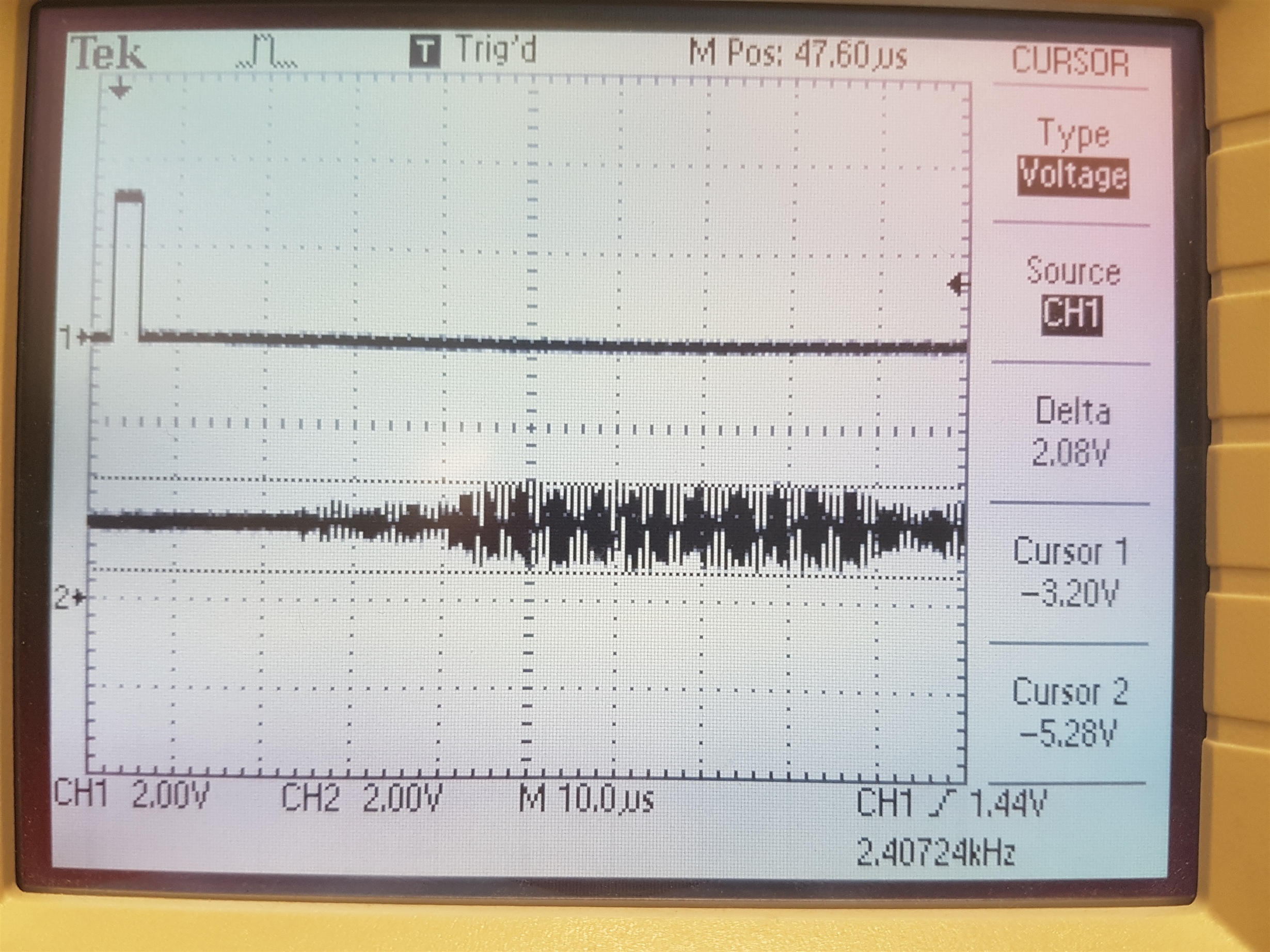

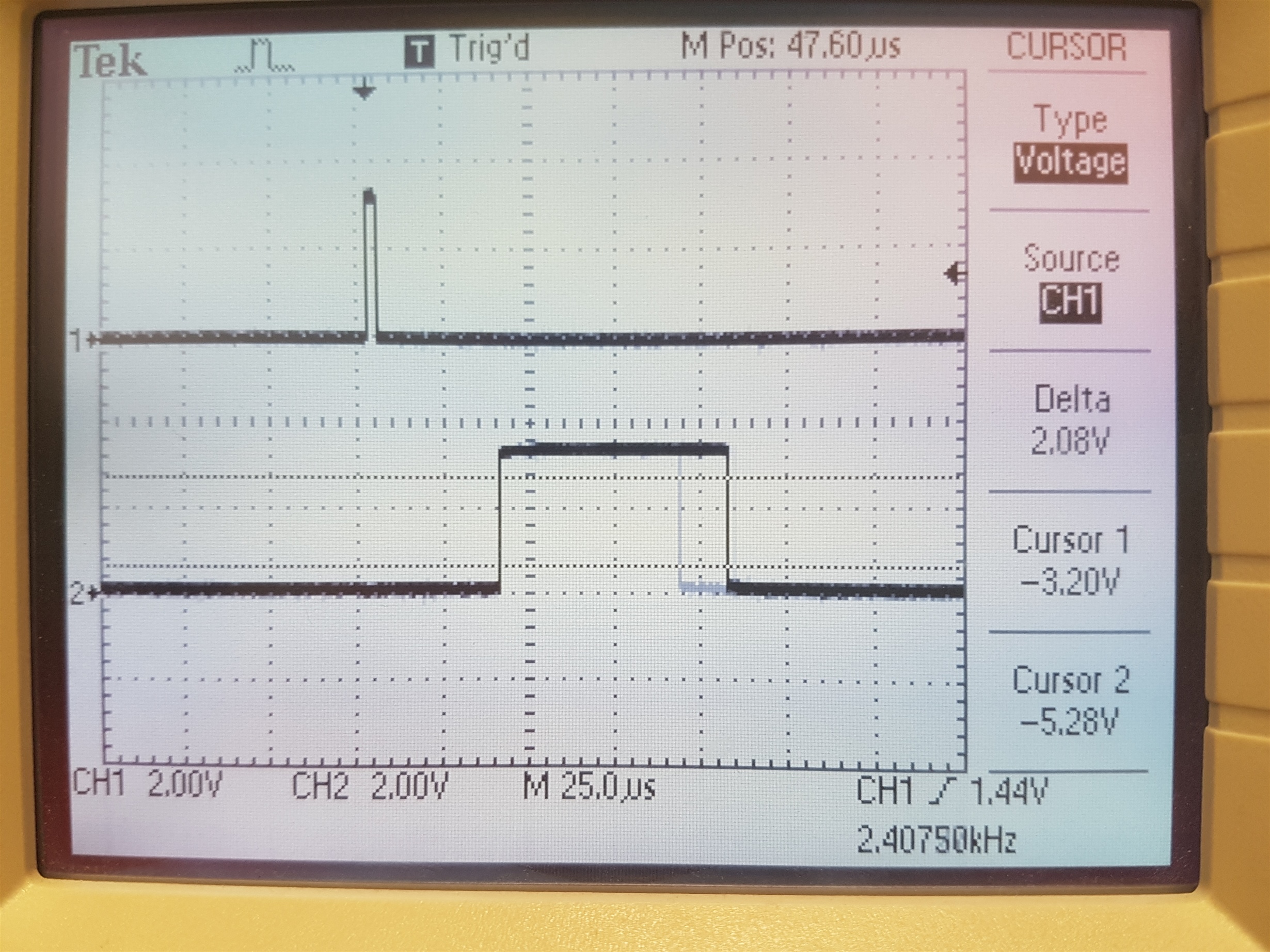

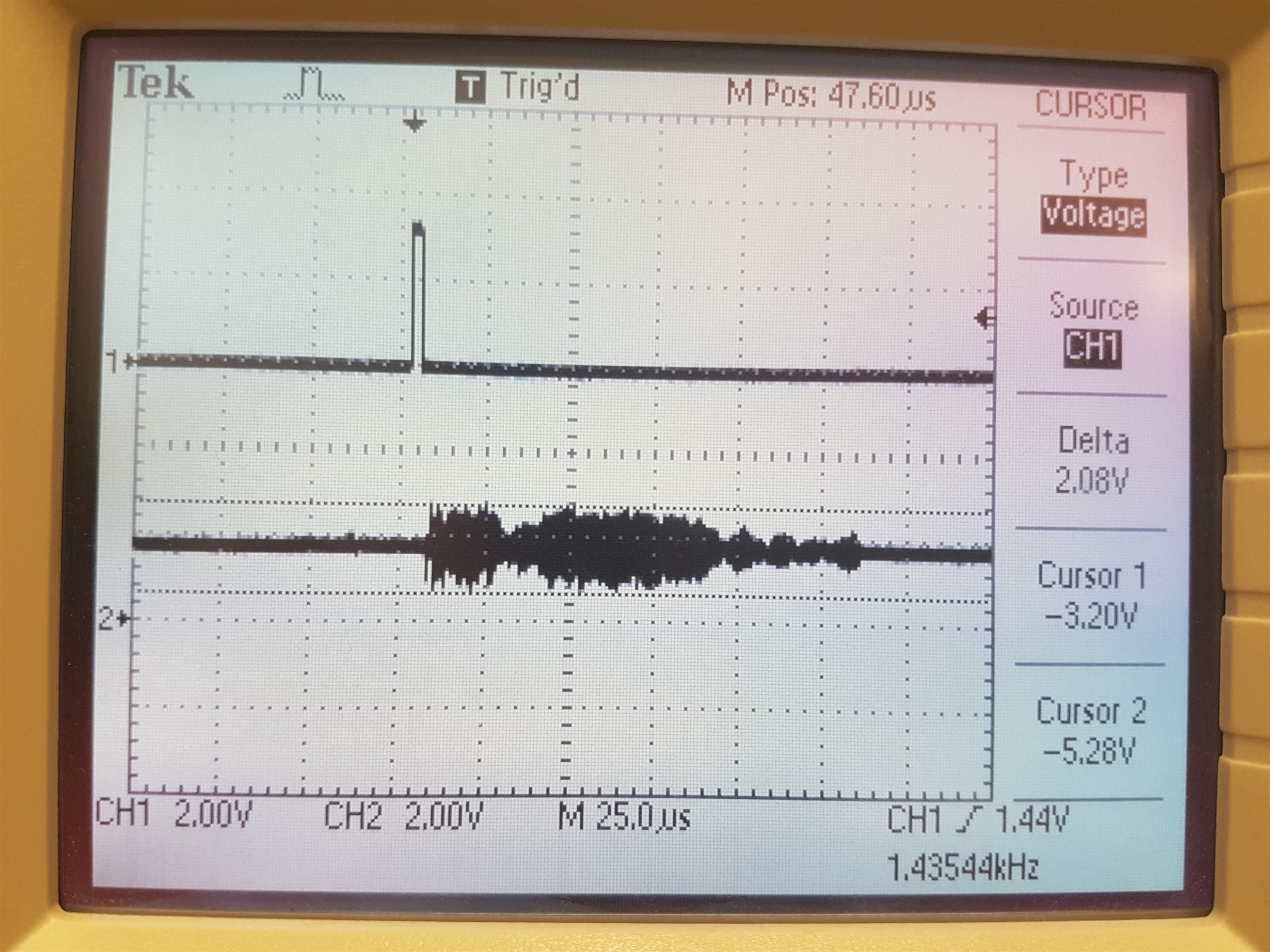

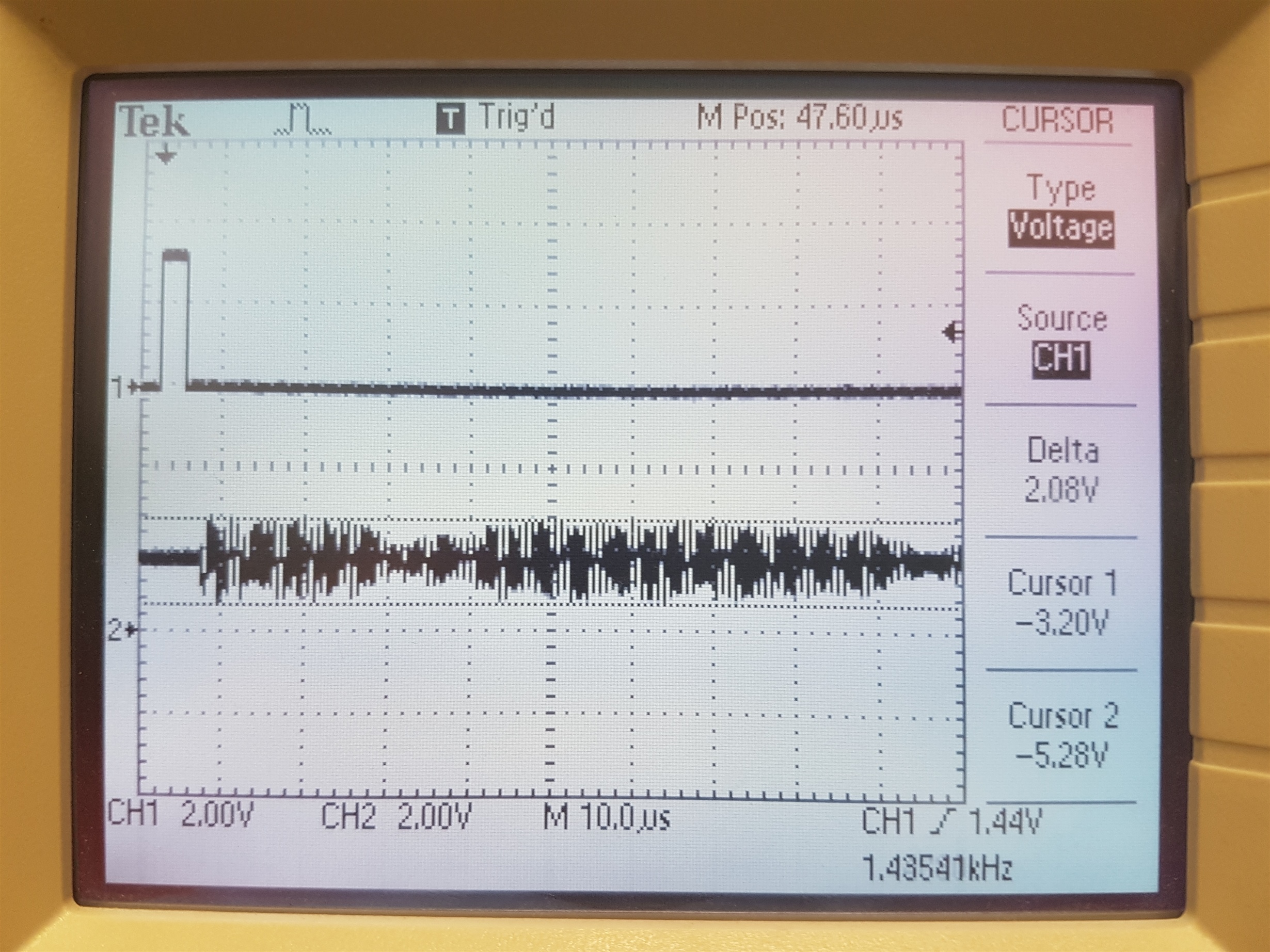

2) Measured Start, Stop & Compin with osciliscope.

CH1 START CH2 COMPIN

CH1 START CH2 STOP

CH1 STOP CH2 COMPIN

3) Tried to move object closer to the transducer and further graphs stays the same.

4) Continued with snaa270.pdf and changed register values of TDC1000.

CONFIG_0

RAW: 0x44

TX_FREQ_DIV: 8

NUM_TX: 4

CONFIG_1

RAW: 0x41

NUM_AVG: 1

NUM_RX: 1

CONFIG_2

RAW: 0x0

VCOM_SEL: INT

MEAS_MODE: TOF

DAMPING: OFF

CH_SWP: OFF

EXT_CHSEL: OFF

CH_SEL: 1

TOF_MEAS_MODE: 0

CONFIG_3

RAW: 0xF

TEMP_MODE: REF, RTD1, RTD2

TEMP_RTD_SEL: PT1000

TEMP_CLK_DIV: 8

BLANKING: ON

ECHO_QUAL_THLD: -1500 mV

CONFIG_4

RAW: 0x5F

RECEIVE_MODE: MULTI ECHO

TRIG_EDGE_POLARITY: RISING

TX_PH_SHIFT_POS: 31

TOF_1

RAW: 0x40

PGA_GAIN: 6 dB

PGA_CTRL: ON

LNA_CTRL: ON

LNA_FB: CAPACITIVE

TIMING_REG[9:8]: 0

TOF_0

RAW: 0x1E

TIMING_REG[9:0]: 30

ERROR_FLAGS

RAW: 0x0

ERR_SIG_WEAK: 0

ERR_NO_SIG: 0

ERR_SIG_HIGH: 0

TIMEOUT

RAW: 0x43

FORCE_SHORT_TOF: ON

SHORT_TOF_BLANK_PERIOD: 8 x T0 -> 100.00 us

ECHO_TIMEOUT: ON

TOF_TIMEOUT_CTRL: 1024 x T0 -> 12800.00 us

CLOCK_RATE

RAW: 0x1

CLOCKIN_DIV: 1

AUTOZERO_PERIOD: 128 x T0 -> 1600.00 us

TOF Control: Short TOF

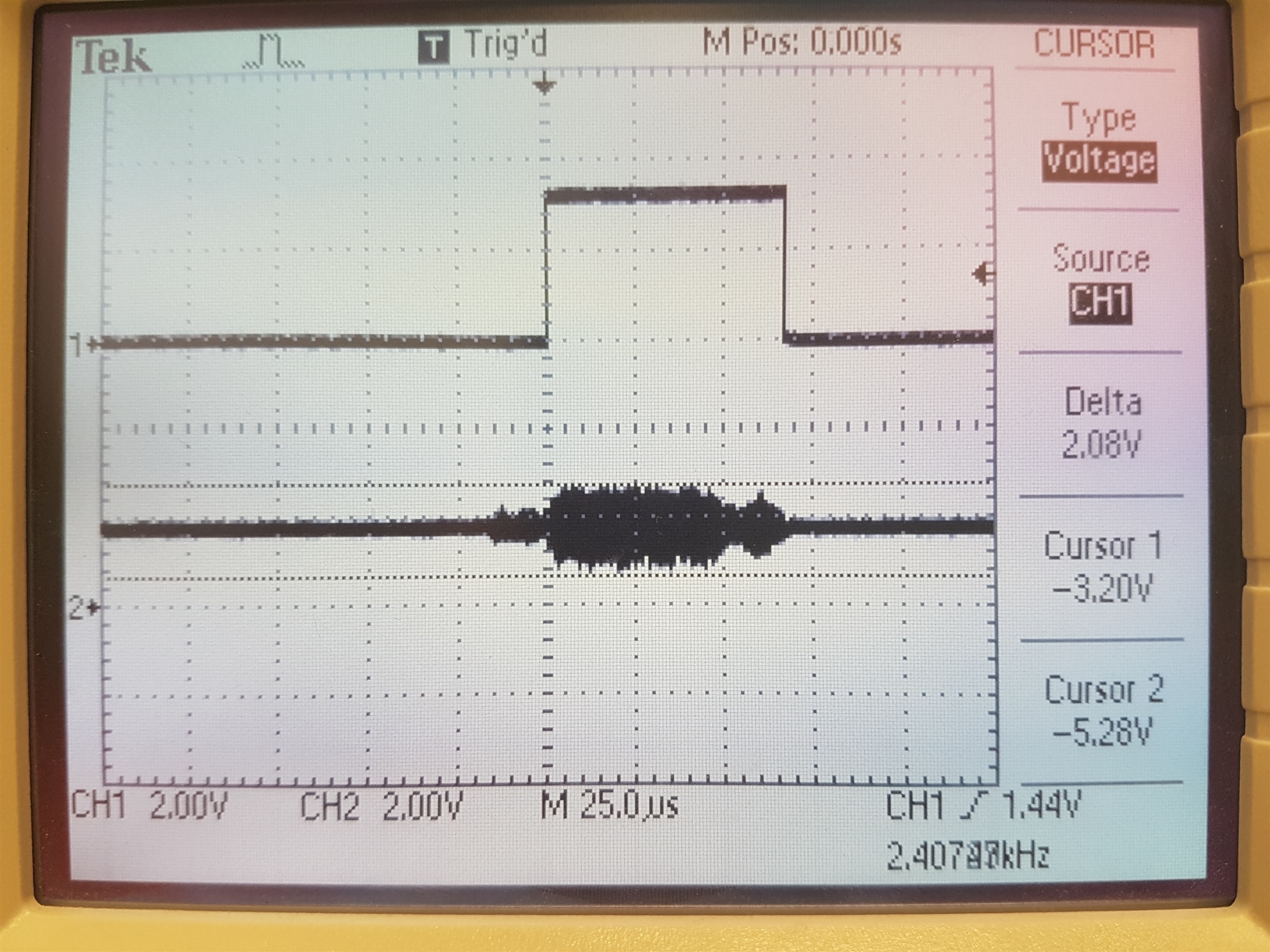

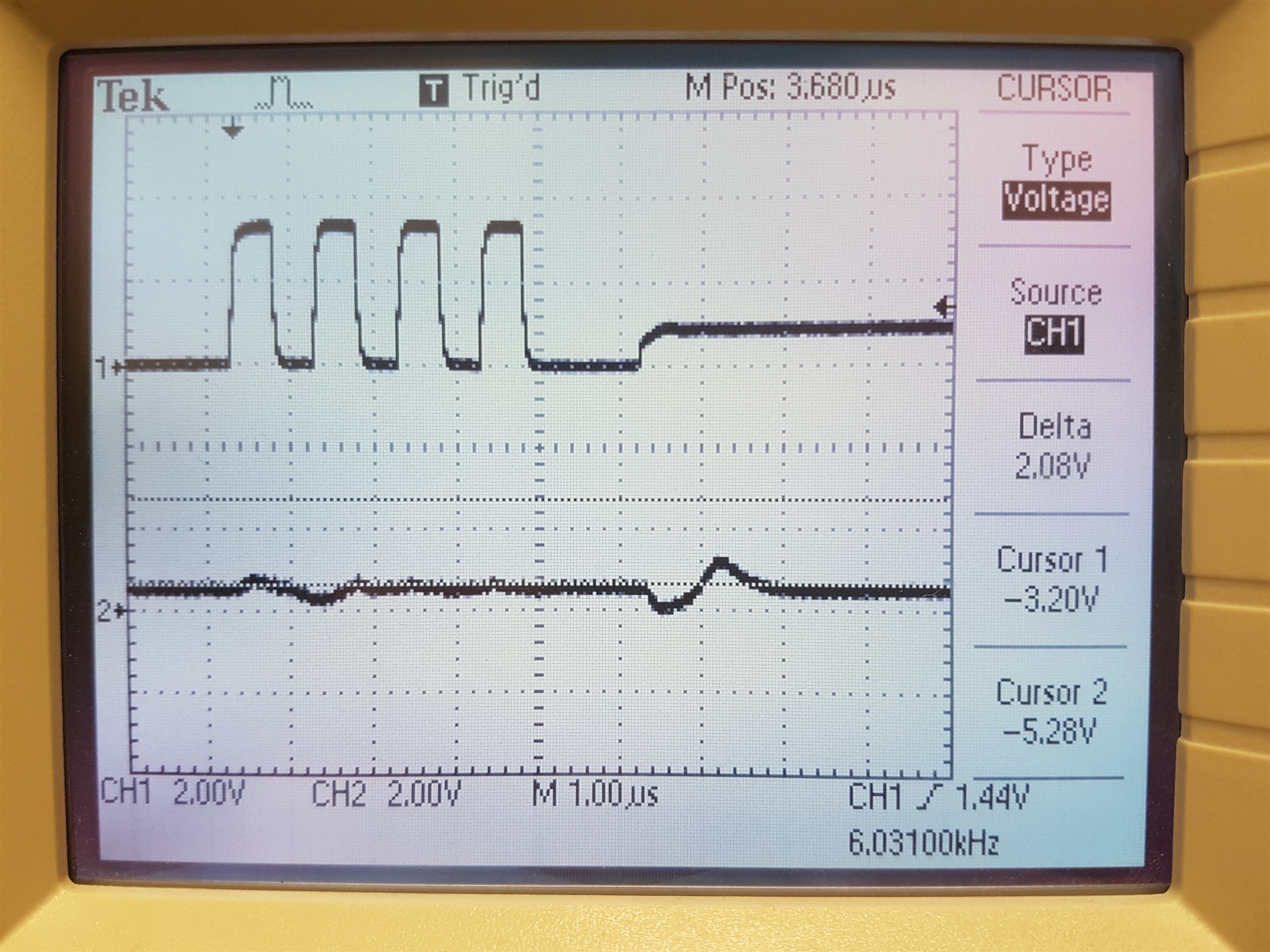

5) Measured Start and COMPIN

CH1 START CH1 COMPIN

This measurements i did just to test that my transducer and circuit is working properly before glueing transducer to the tank. So between object and transducer there is an air instead of water. I assume that ToF still should vary depending on the distance between transducer and object. Thank you.

Kind regards,

Gytis