Other Parts Discussed in Thread: FDC2214,

Dear TI

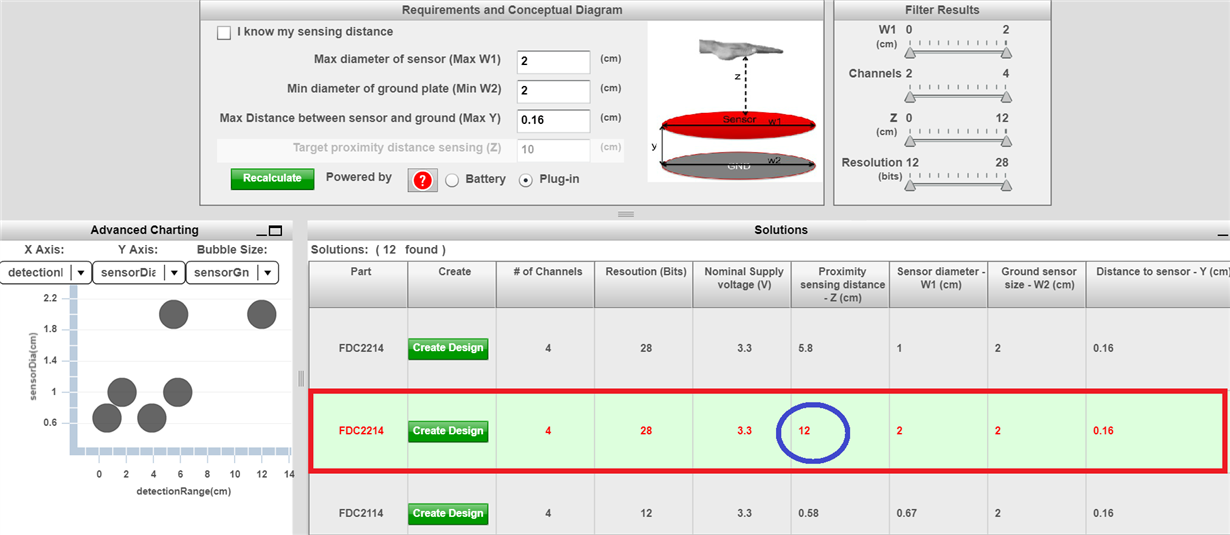

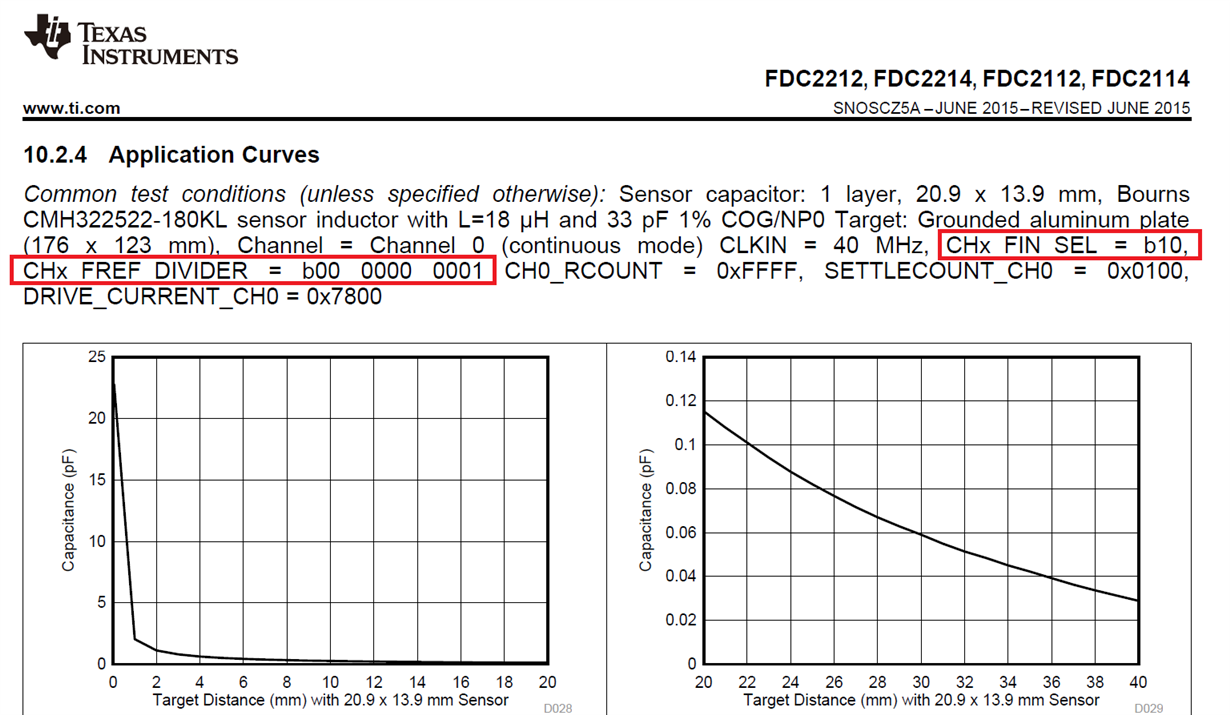

I used a webench designer tool to calculate the sensor diameter and its proximity sensing range. The results in the figure below.

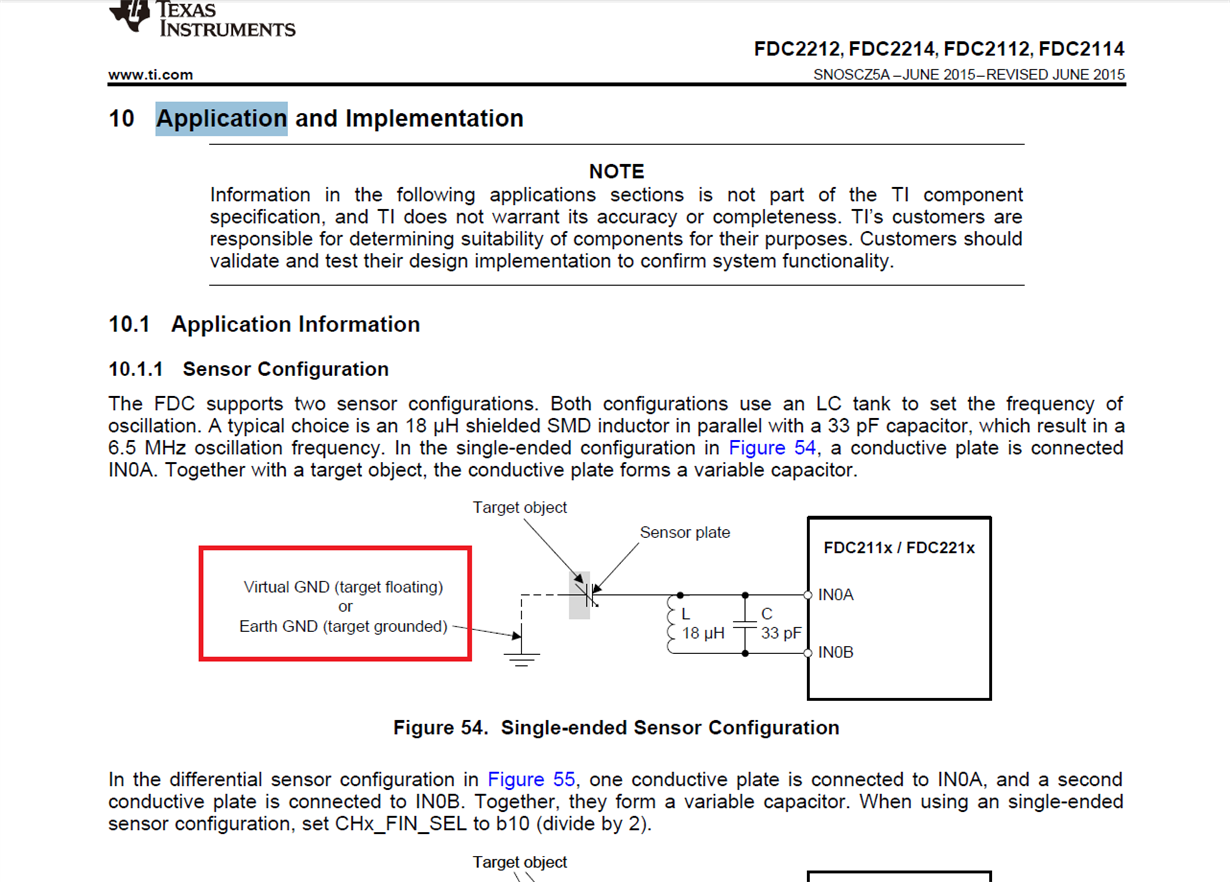

I am using a FDC2214 EVM with our own SENSOR PLATE which has a diameter of 2 cm connected to INA and GROUND PLATE with a diameter of 2 cm connected to INB of Channel 3.

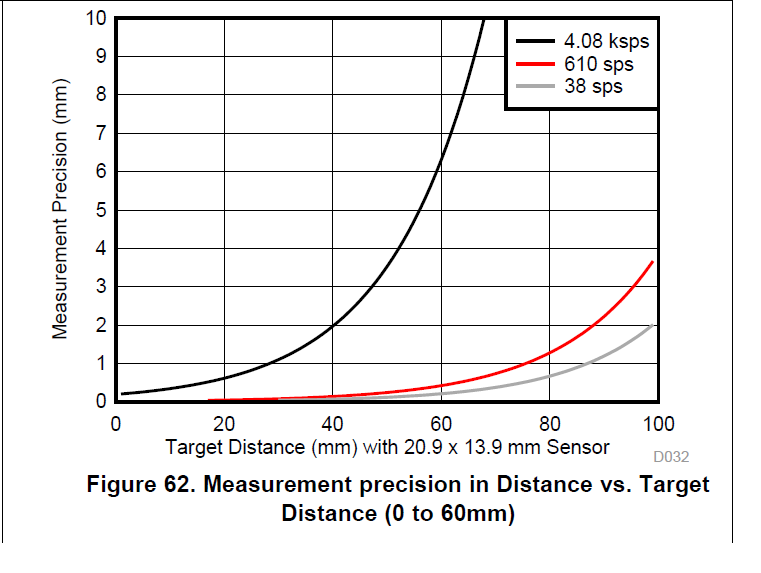

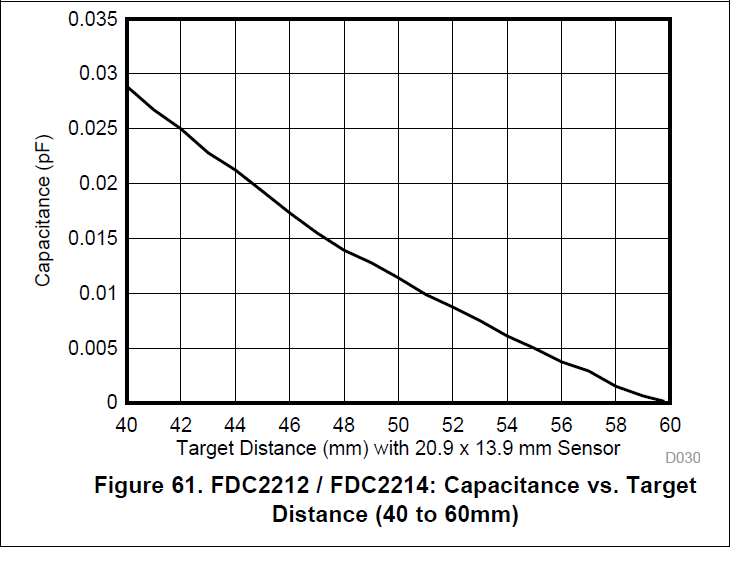

Distance between sensor and ground plate is 0.16 cm (PCB thickness), but the proximity sensing range didn't reach to 12 cm. Its only 3 cm.

Here are my questions:

1. How to get this kind of proximity sensing range by using the same sensor diameter?

2. What parameters or components have to change?

3. Does the configuration of sensor is correct ?

Waiting for your response. Thank you!

Best Regards,

Janine Lin