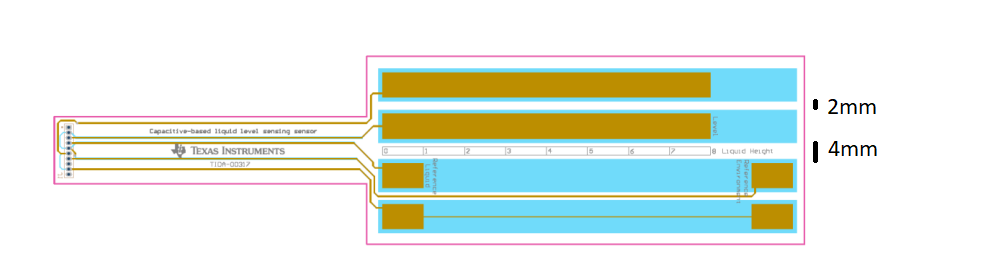

Other Parts Discussed in Thread: TIDA-00317, FDC1004

Hello;

I am trying to deisgn level sensor with fdc2212.

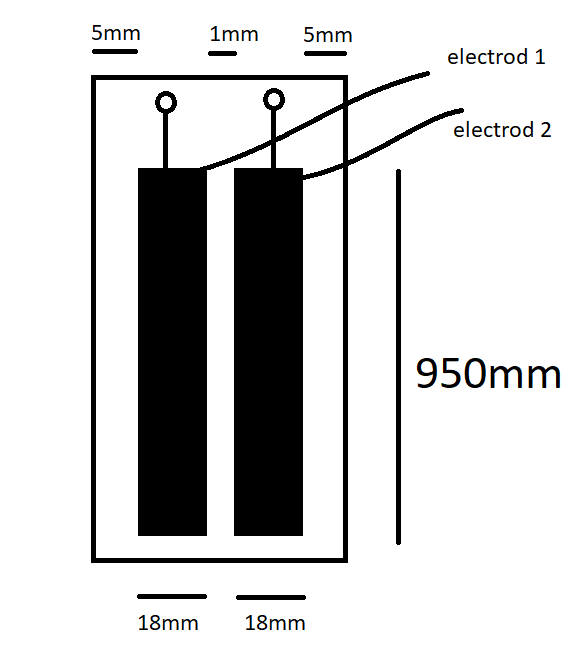

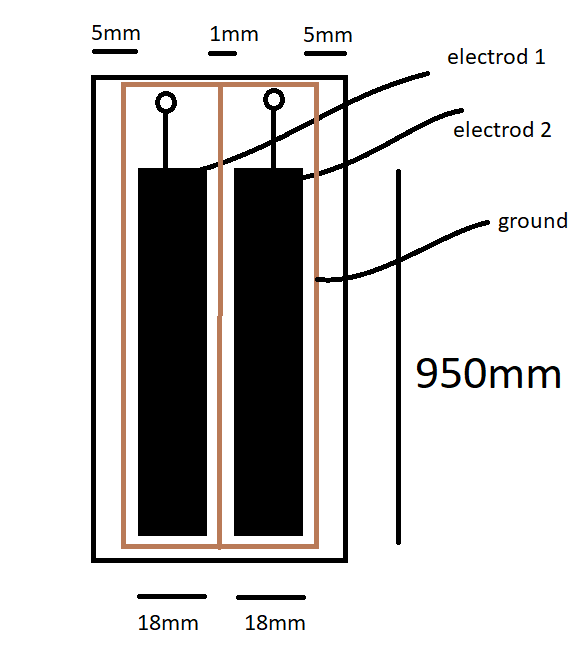

I have a FDC PCB, an PCB elecrod to use meuasre capacitive which have two cu plane and aluminium encloser. Aluminium has grounded. PCB electrod and FDC PCB is stable in Aluminium encloser.

FDC PCB also in aluminium encloser. I use single ended sensor configuration to measure capacitor of PCB electrod.

L CMH series 22uH, C 100pF NPO, RCOUNT=0XFFFF, SETTLECOUNT= 0XFFFF

PCB electrod is shown above. When I connect to IN0A to electrod 1 and IN1A to electrod 2 on auto scan conversion mode, capacitor value is 72pf and 70pF respectively.

But When I connect to IN0A to electrod 1 on single conversion mode, capacitor value is 75pf , When I connect to IN1A to electrod 2 on single conversion mode, capacitor value is 75pf.

*Electrods effect each other, How I cancel this effect?

*Is 1mm distance between electrods enough?

What is your offer for sensor design?

Best Regards.