Other Parts Discussed in Thread: OPT3101,

Hello,

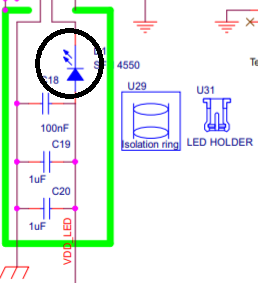

I am trying to test my fabricated VCSEL and photodiode as a function of time-of-flight. Are these parts also possible to connect to the product? Is there any power or current restriction?

And also can I add external laser driver circuit to further speed up the laser pulse? Thanks!

Best,

Ted