Other Parts Discussed in Thread: LDC1614EVM

Hi,

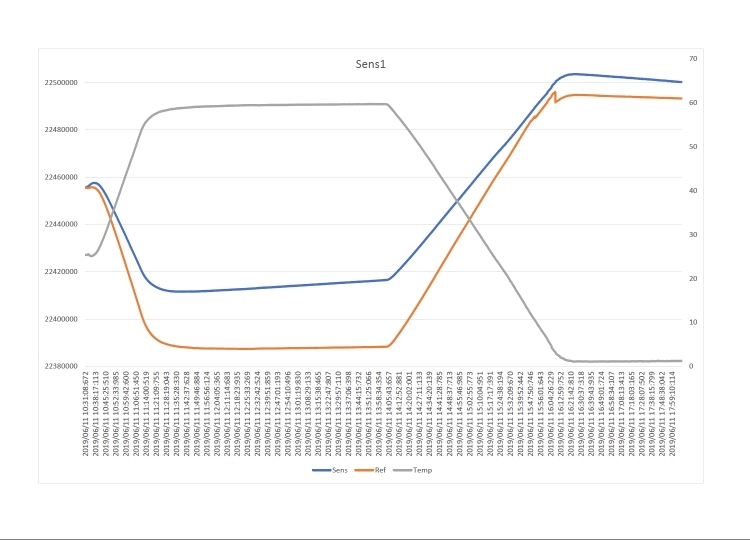

I am using LDC1612 to measure distance of a metal object (shape to be defined) near from one to three millimeters to the coil sensor and I have problems with temperature variation.

A second coil has been provided as a "reference" for compensation of temperature variations. The "main" and "reference" coils have the same designe of LDC1614EVM sensors: 13.9mm, 19 turns/layer, 2 layer, 0.15mm trace width and 0.15mm trace spacing.

The heating tests in a climatic chamber from 0 to 60 ° C on different sensors have given different results with significant differences both as a variation of the "main" channel with respect to the "reference" channel, and between sensor and sensor. The relationship between the "main" channel and the "reference" channel is different for each sensor.

For the test we glued a 1mm plastic spacer and a metal washer (diameter 14mm) on both the "master" and "reference" coils.

Do you have any suggestions or indications for the application and in particular for the best solution to compensate for temperature variations?

thank you

Best Regards,

Samuele