Other Parts Discussed in Thread: , LMT70

Greetings Everyone,

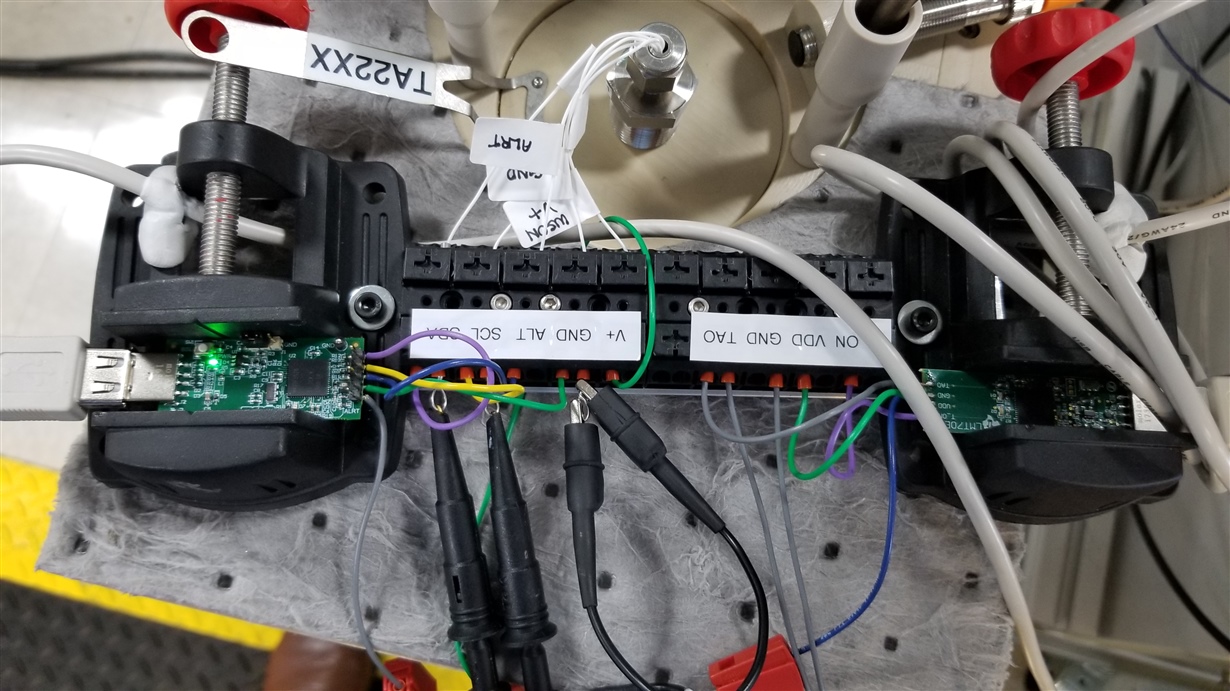

We're evaluating the TMP117's accuracy in our thermal baths using the TMP117EVM. We're encountering a device disconnection/ connection time out from the TMP117 itself towards the EVM and or the GUI software. Out test samples have your TMP117 (both WSON and BGA packages) mounted on a flexible film which is then glued inside a stainless steel probe, welded shut. The tip of this said probes were submerged in thermal baths (distilled water).

At 23°C, the device functions as intended.

At 60°C, we can get intermittent disconnections, but we cannot reproduce the problem reliably.

At 90°C, the TMP117 disconnects from the EVM/ GUI software almost instantly (within 4 seconds) across all 10 sensors we have built. We can delay the disconnection by increasing the conversion averaging and conversion cycle, but the most we can get is 16 seconds before it inevitably disconnects as well.

Worst of all, even at its one-shot (shutdown) mode, the sensor would still disconnect. I'm assuming that the "Hardware not Connected" message shown on the lower left corner of the GUI whenever the problem occurs indicates a disconnection of the TMP sensor, not the EVM.

We're seriously hoping that this is a software issue and not the TMP117 itself. We're using the GUI software version 1.2.1 for the TMP117EVM. We did not see any mention of thermal shutdowns on the datasheet (just SHE effects). If this is indeed a thermal shutdown at 60/ 90°C then this sensor would be of no use to us.

Any help is appreciated!

/Ches