Other Parts Discussed in Thread: LDCCOILEVM, LDC1614

Hi Sir,

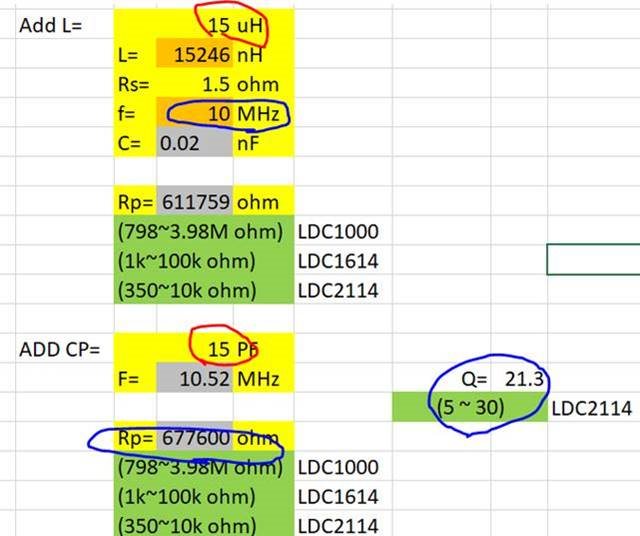

We uses LDC2114 EVM and setup: L=15uH (MLZ2012M150W), C=15pF (NPO)

These values will:

fsensor=10MHzèok

Q=21.3èok

Rp=612Kè over spec (350~10K ohm)

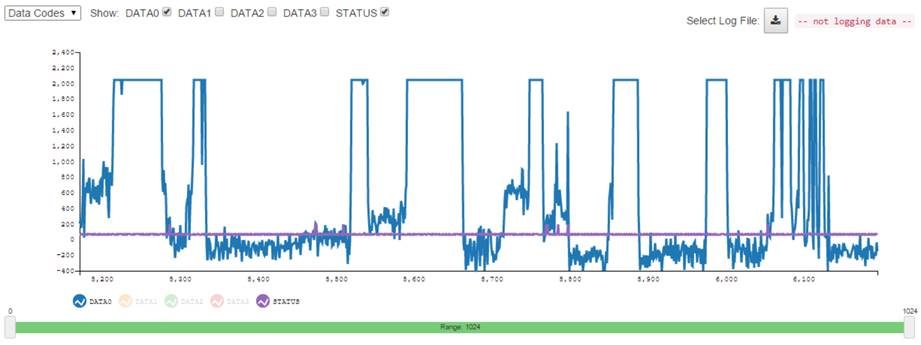

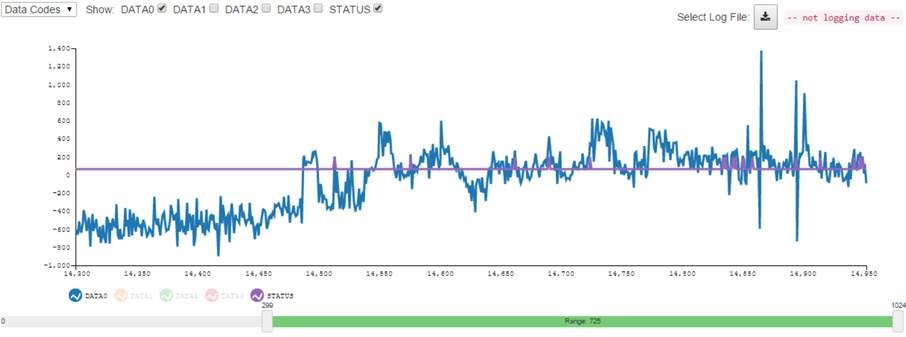

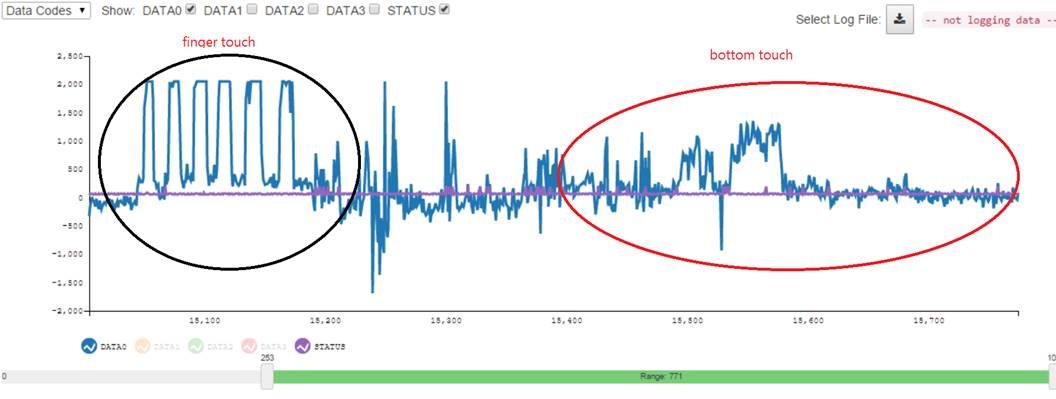

But it looks not working on EVM, would you pls advise how we can let EVM working formal?

Thanks, Ian.