Part Number: TDC1000-TDC7200EVM

Hello,

I have problem with getting result obtained in "UltrasonicSensingfor WaterFlowMetersand HeatMeters" (Application Report SNIA020).

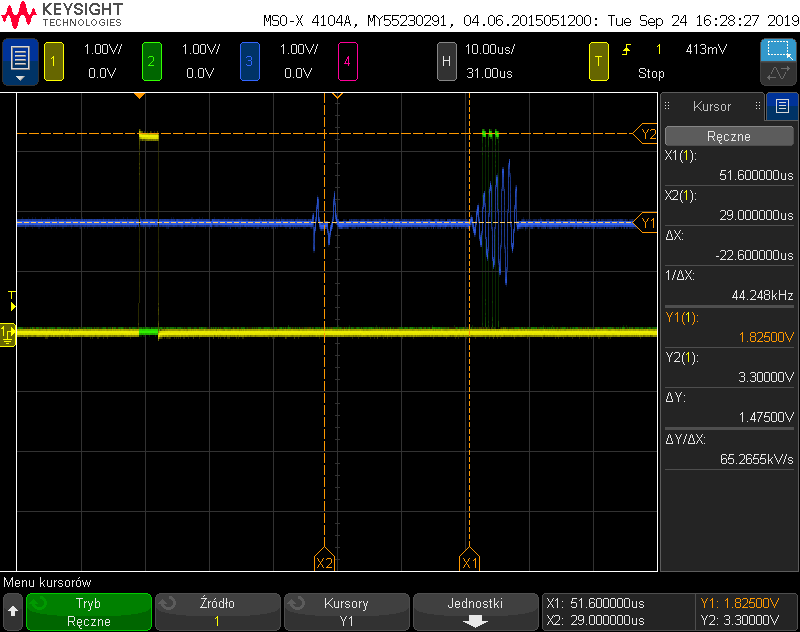

I use transducers US0019 (by audiowell with Resonant impedance ≤220Ω; frequency 980±30KHz; Static capacitance 550±20%pF), TDC1000, TDC7200 and switching circuit

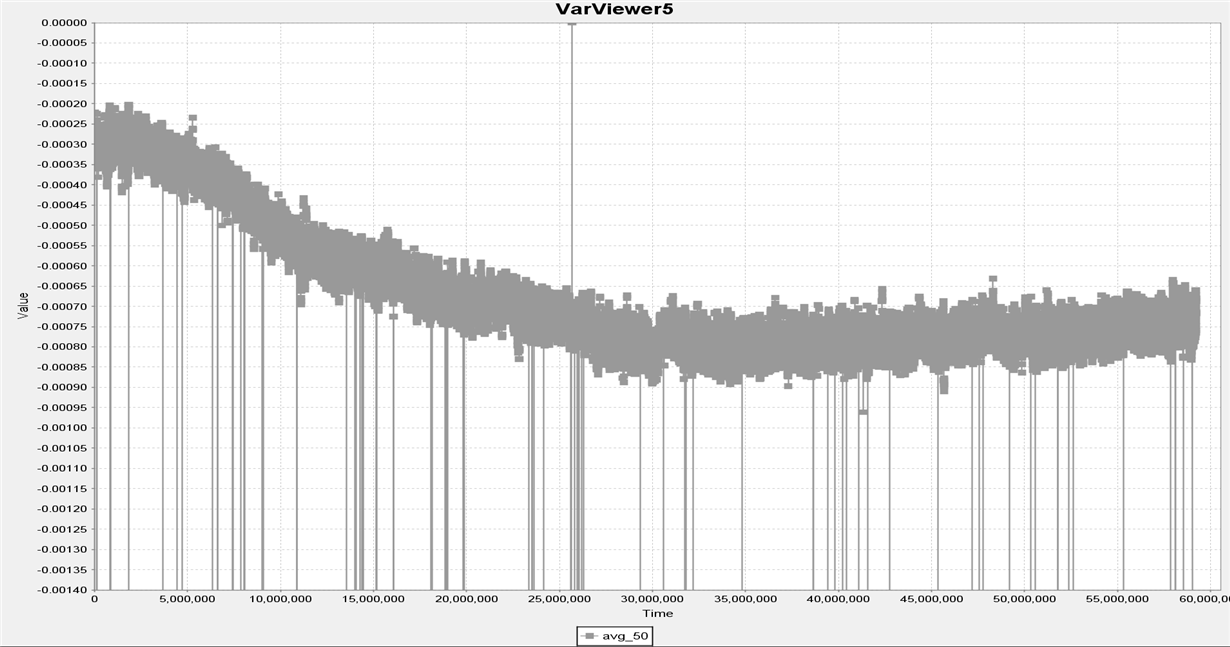

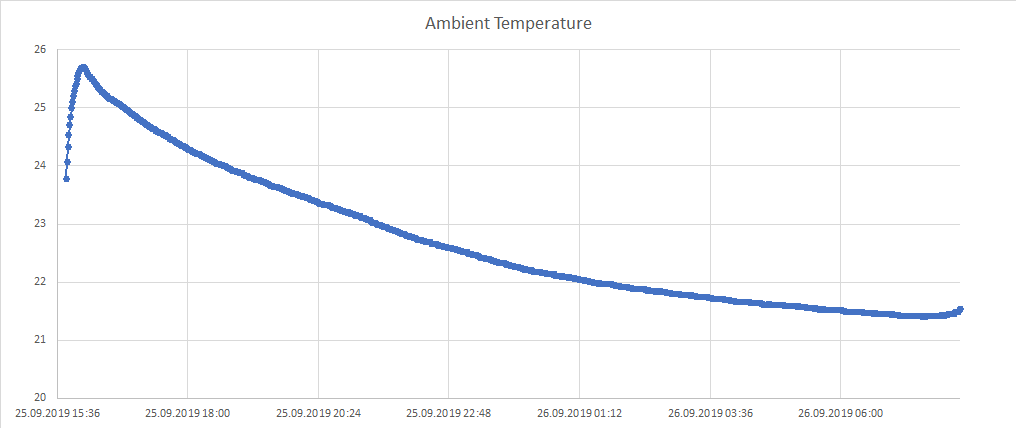

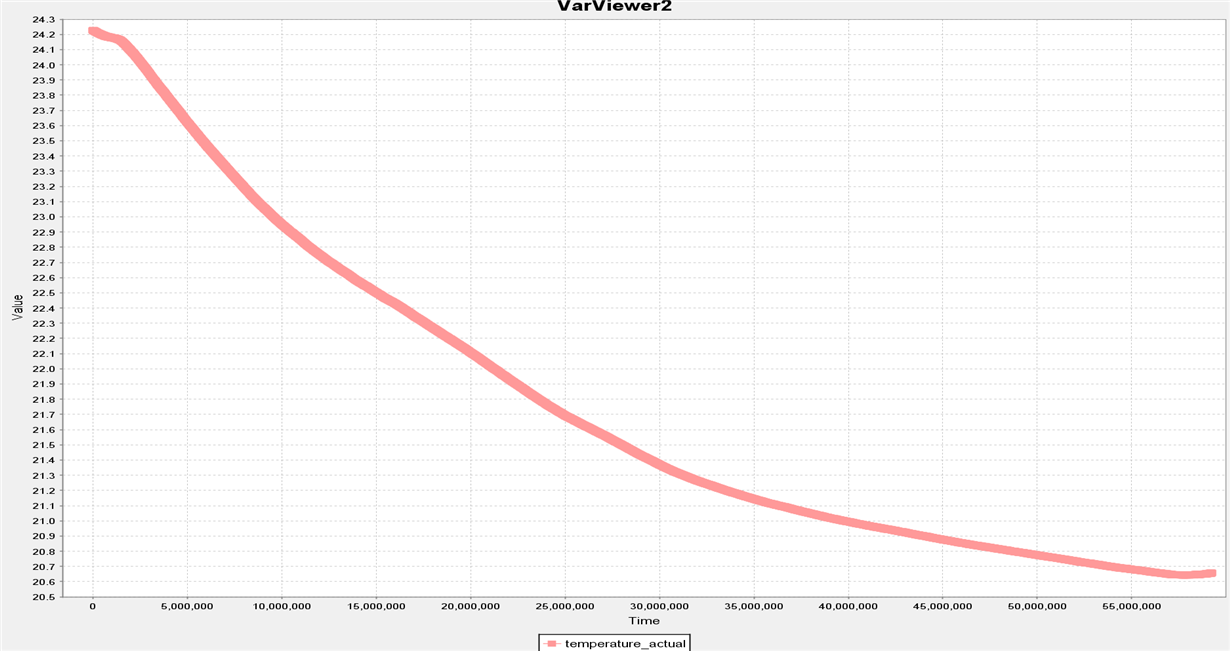

I used values from document above and made a lot of sweeps of values and my deltaTOF is still floating in range -500/+500ps in best case. No metter of temperature within minutes.

Do you have some guides of how to pick out resistors values and RX parrarel capacitor to make more preciese measurements.

Looking forward for your reply.

Best Regards,