Other Parts Discussed in Thread: FDC2114, FDC1004, FDC1004EVM

Dear Sir/Madam,

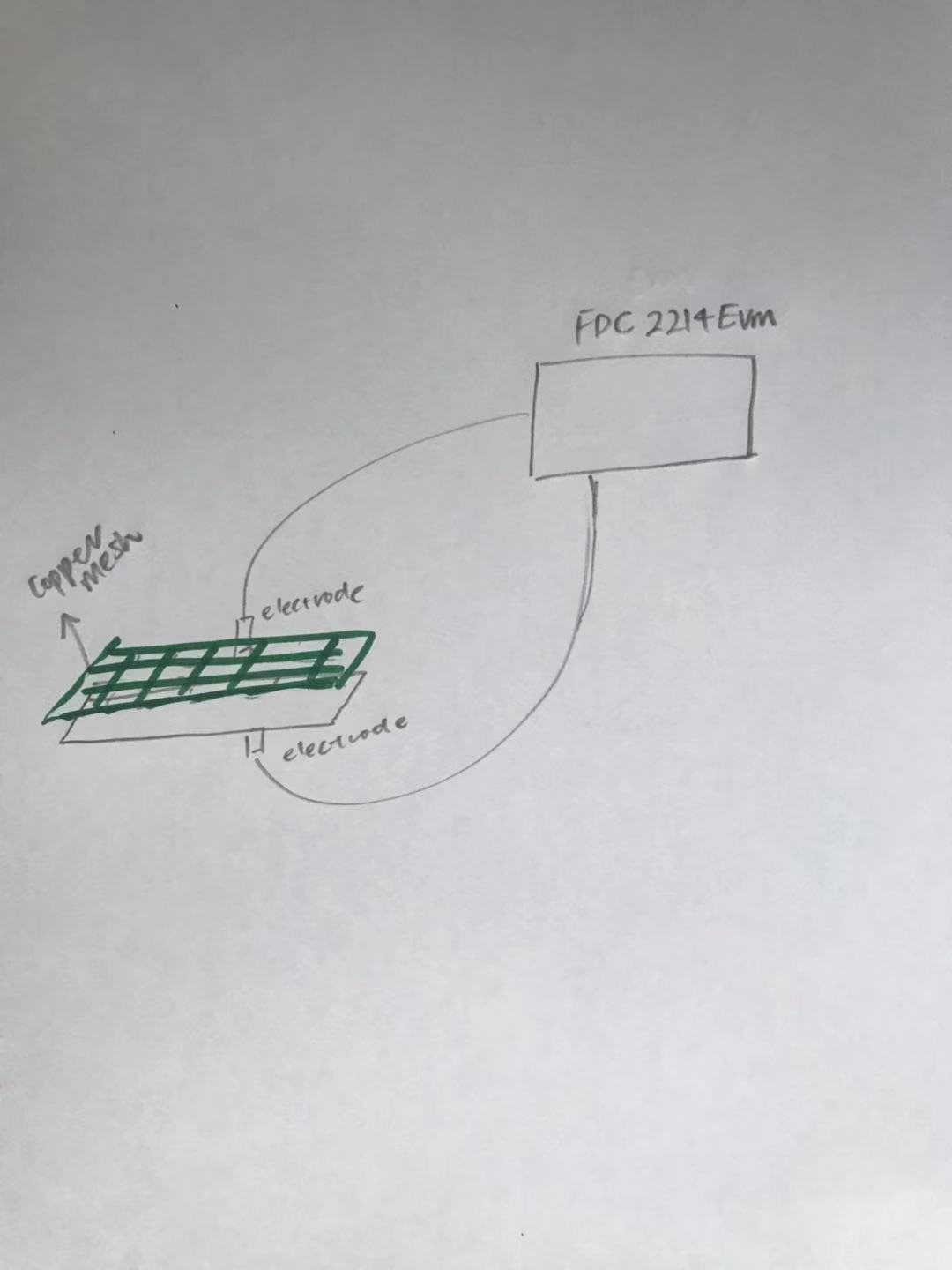

I having difficulties with understanding how to connect FDC2214EVM to my custom sensors.

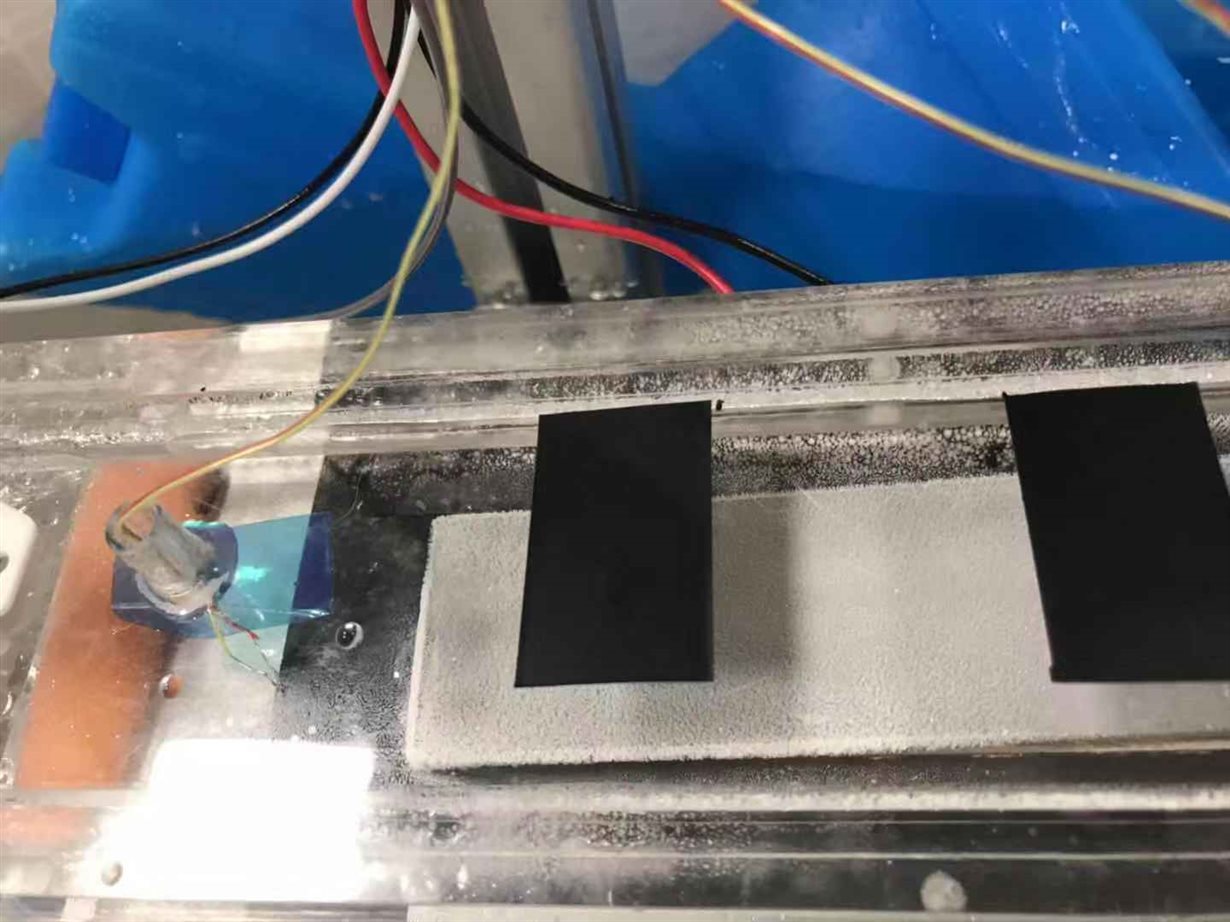

In this EVM, there are two capacitive sensors attached to it, which can be detached , do I need to attach this capacitive sensor to copper mesh? does this capacitive sensor act as an electrode in the picture shown

Then how detached captive sensor is connected to the EVM after detached, is it through the use of connection wires?

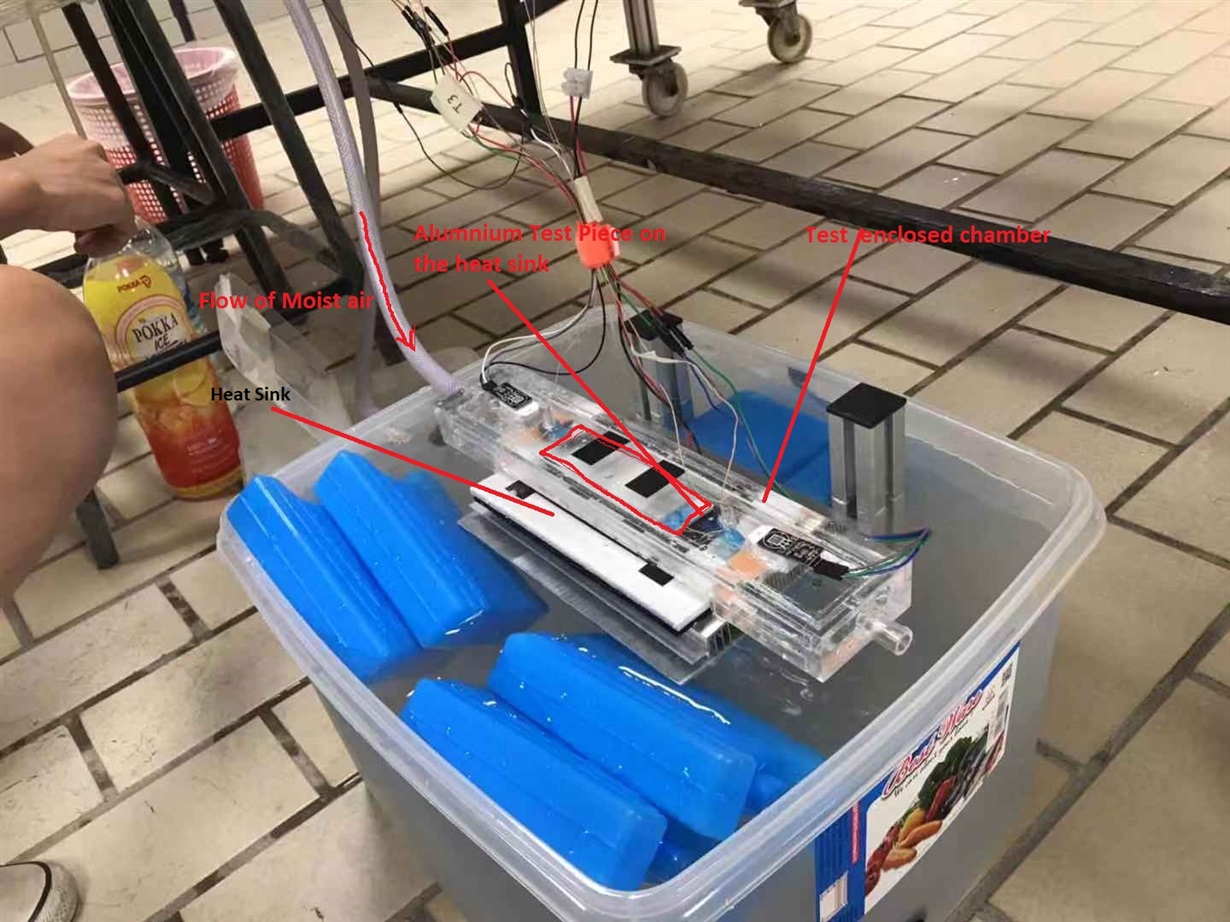

I am testing ice thickness on a flat plate in a humid environment. Kindly confirm with me whether my concept on using FDC2214EVM is correct.

Best Regards,

Qiuping