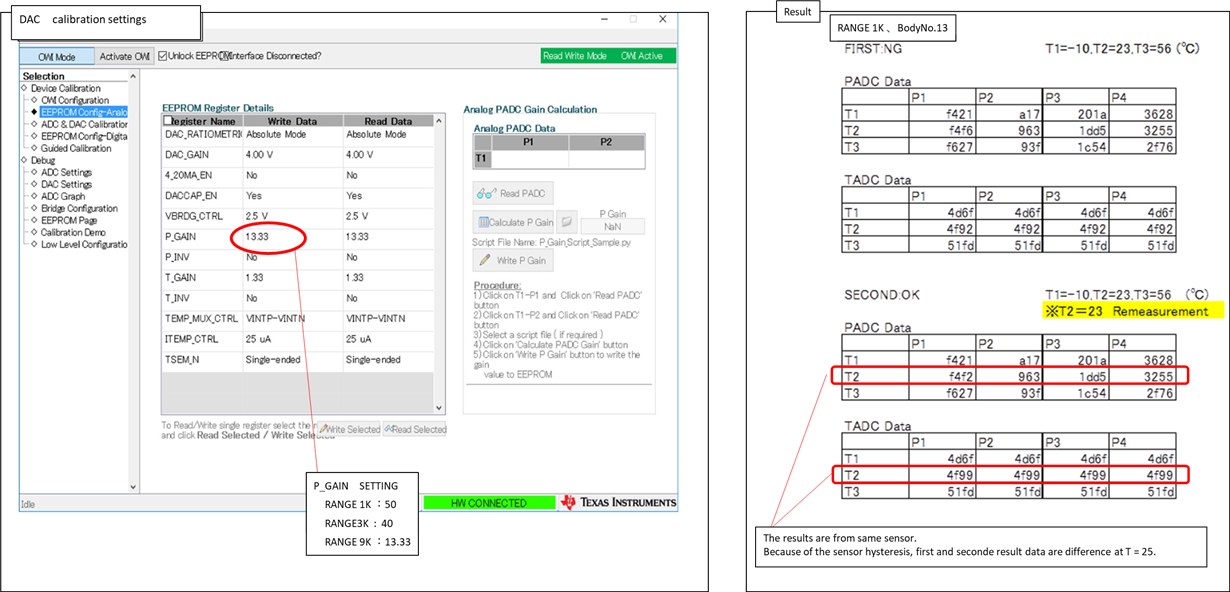

We use PGA300 EVM-034 GUI for getting Internal certification.However, we often didn’t get temperature compensation coefficients that use for pressure compensations. If some conditions that need for calculating temperature compensation coefficients exist, please tell us these criteria.

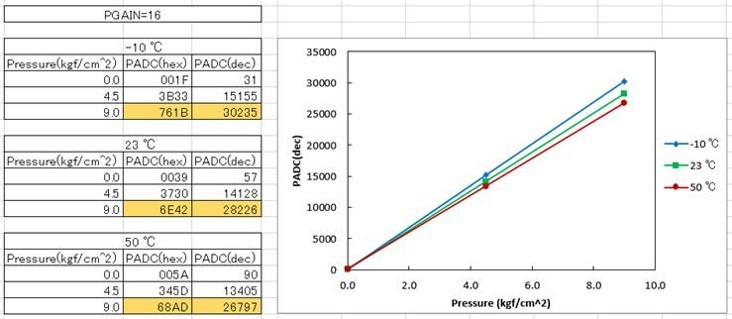

Measurement conditions

1) 4 pressure points and 3 temperature points

2) Keep each temperature in 3 – 4 hours using by temperature chamber

(Temperature: -10℃, 23℃, and 50℃)

3) Pressure ranges: 1, 3, and 9 [kgf/cm^2]

4) Applied pressure 0%, 33%, 66%, and 100% in each pressure range

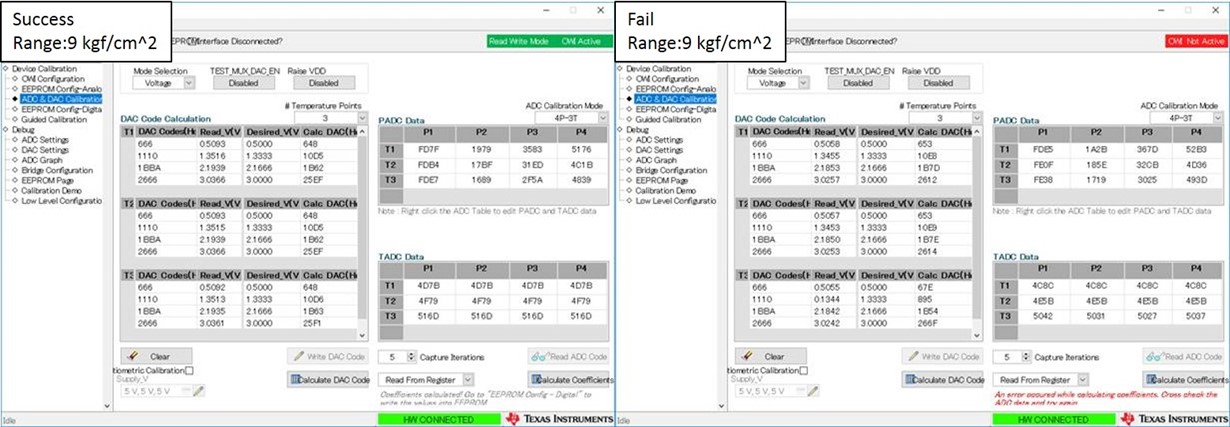

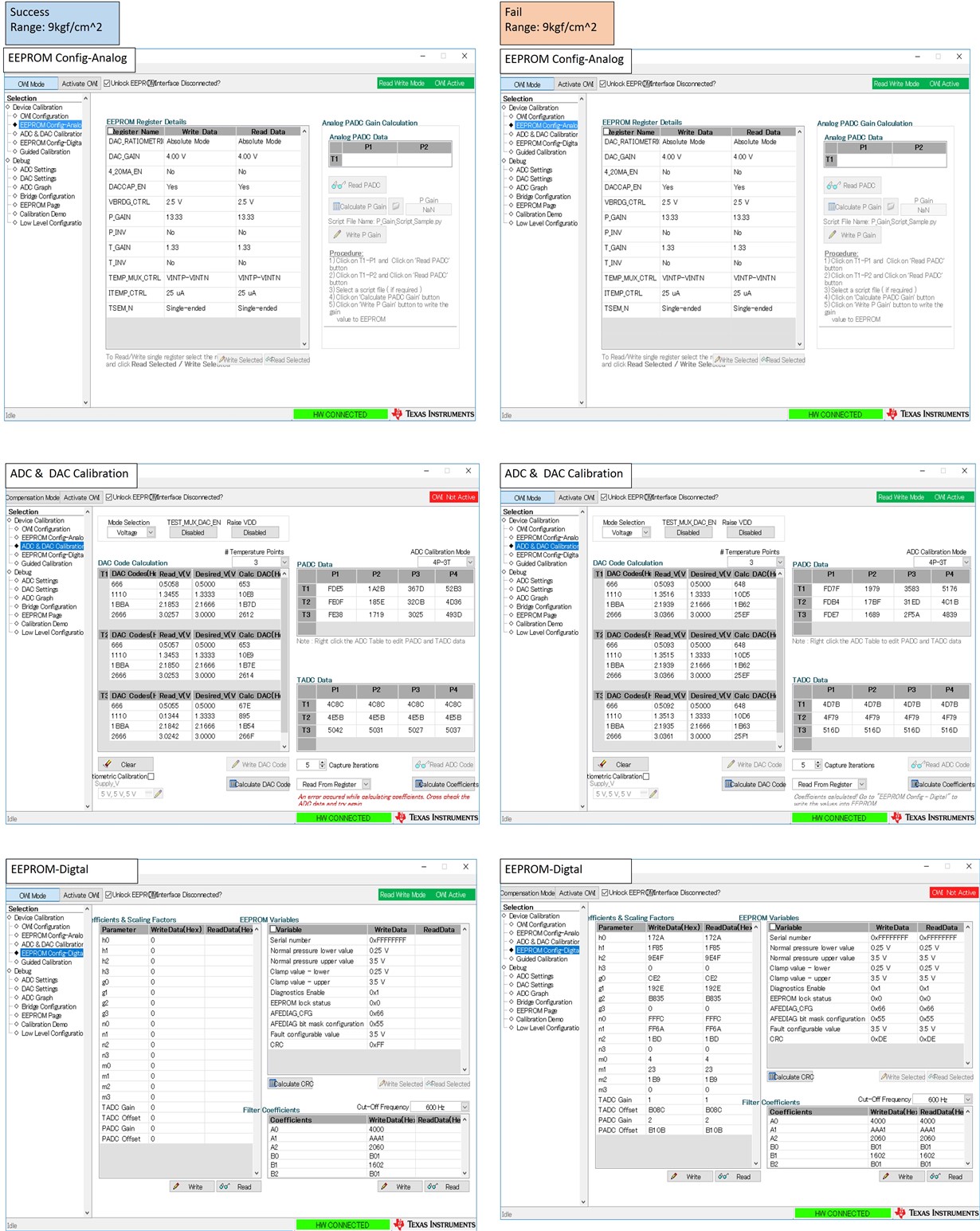

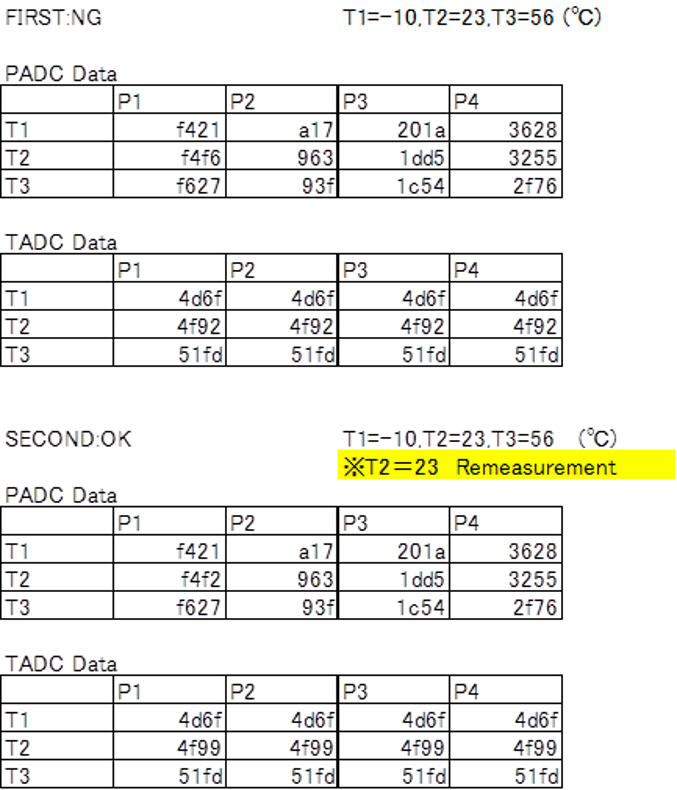

These examples are about success and fail.