Other Parts Discussed in Thread: FDC2114, FDC1004

Hi,

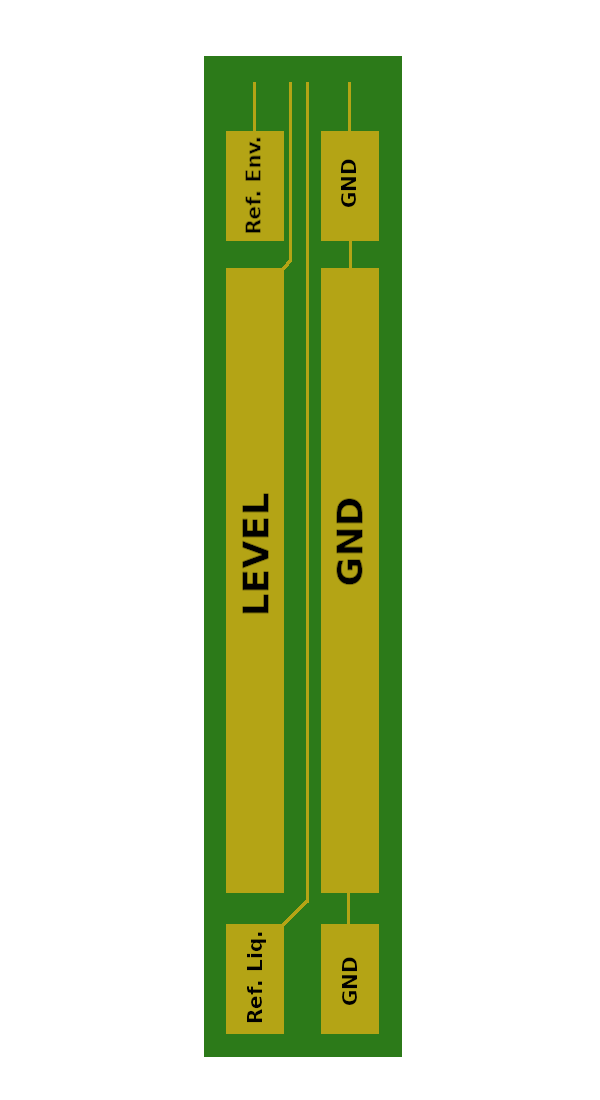

We are prototyping capacitive measurements for level measuring on a cylindrical container with a diameter of approximately 30 cm. The sensor electrodes are about 50 cm long. We have seen some promising results with single-ended measurements using copper tape. Ideally we would use differential measurements in order to filter out as much outside disturbance as possible. However, when testing differential measurements, we run into problems.

The simplest differential setup uses two electrodes, one connected to CIN1 and the other to SHLD2, and the measurement is defined as CHA = CIN1 and CHB = CIN4 (which is floating but in-phase with SHLD2, if I have understood this correctly).

The differential measurement immediately goes into saturation. Adding a large negative offset capacitance seemingly moves the measurement out of saturation again (to about 14 pF), but the measurement just stays at the same exact level and does not vary at all, so it still seems to be locked/saturated somehow. What is happening here?

Also: The FDC1004EVM has two pins for SHLD1 and two pins for SHLD2. Is it just the same which of the two pins (for the same shield) I use, or are they wired differently somehow?