Other Parts Discussed in Thread: IWR1642, AWR1243,

Hello

I am thinking about using the interference detection function of IWR1443 or IWR1642.

Please tell me the following questions.

・Can you tell me the relationship between binary data and primary / secondary data?

Is the following recognition correct?

(case1)

The conditions are described below.

DCA1000+IWR1642

Num ADC Samples = 111pt

Num Slices = 19(dec)

Time slice num Sample=10(dec)

Data Format = CP_ADC_CQ

(case2)

The conditions are described below.

DCA1000+IWR1443

Num ADC Samples = 416pt

Num Slices = 31(dec)

Time slice num Sample=26(dec)

Data Format = CP_ADC_CQ

・the time slices consist of “Primary” and “Secondary”.

Would you tell me purpose of “Secondary” time slice.

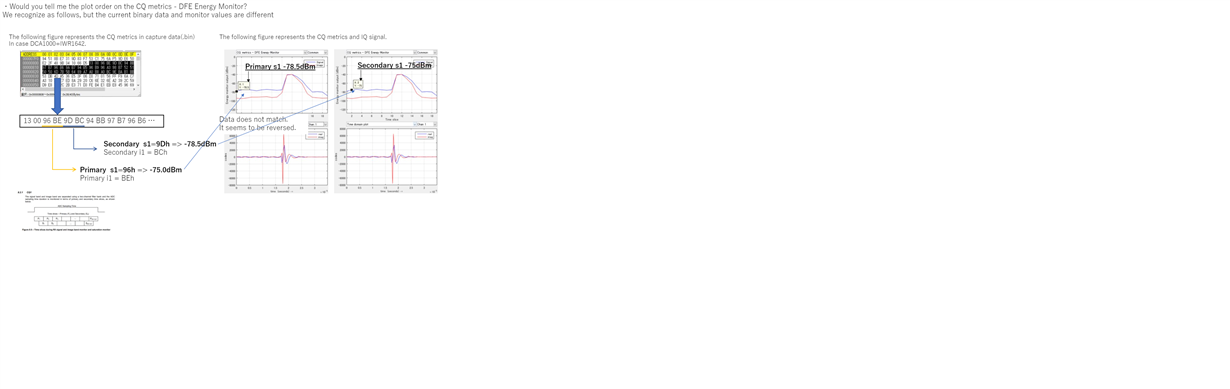

・Would you tell me the plot order on the CQ metrics - DFE Energy Monitor?

We recognize as follows, but the current binary data and monitor values are different

Regards