Tool/software: TI C/C++ Compiler

Dears,

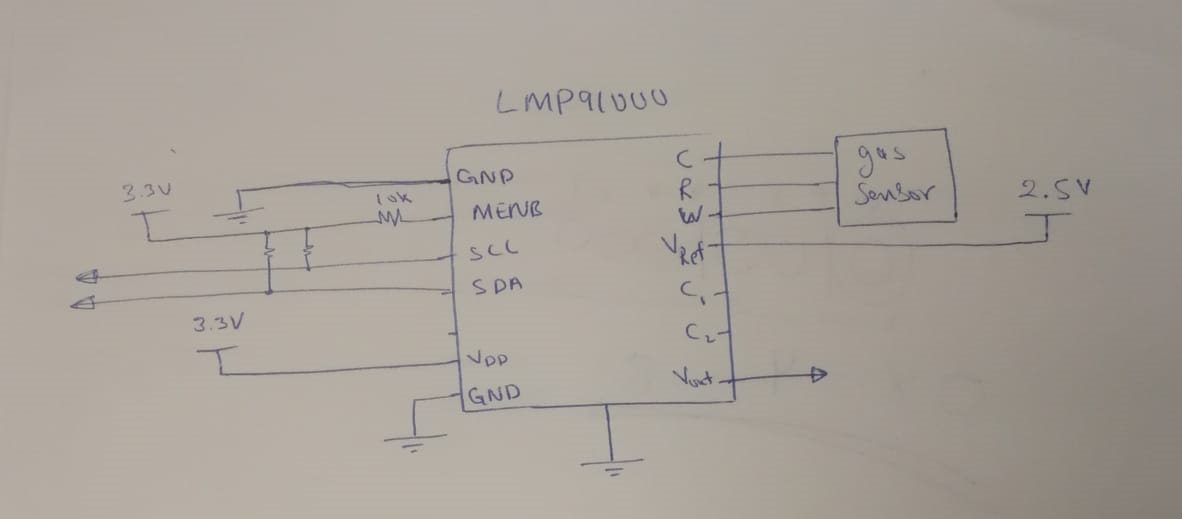

We are working in our project where we are trying to use you chip (LMP91000) to read the Oxygen concentration using Euro-Gas micro O2 sensor.

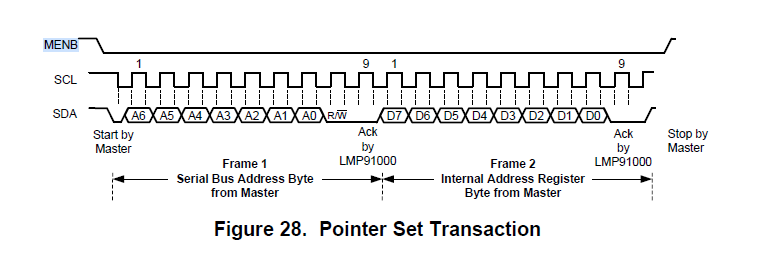

In fact, we changed the parameters to be compatible with the gas sensor but there is not change in Vout pin.

Could you please help us to understand what is wrong with setting that we did and what are the setting that are going to work with our sensor.

Please, find data sheet of the oxygen sensor that we are using.

We are looking forward to your kind help and support...

Regards,O2_SS_Micro (0-25%).pdf