Hi Kristin

If you think SUS304 is hard to make material, we consider switching to copper or aluminum.

I use excel to calculate as below, please give me some suggestions.thanks.

1. The table uses copper as the material. The recommended skin depth is 3 = 20.7 * 3 = 62.1um, which is the thickness of the conductive material copper.

Do you have a recommended distance for copper skin depth? It is same as aluminum?

I increase the material thickness, the excel formula will not change.

The percentage of current higher is better?

2. The table uses aluminum as the material. The recommended skin depth is 3 = 26.1 * 3 = 78.3um, which is the thickness of the conductive material aluminum.

The recommended skin depth for aluminum is 5 = 26.1 * 5 = 130.5um, which is the distance between the coil and the conductive material.

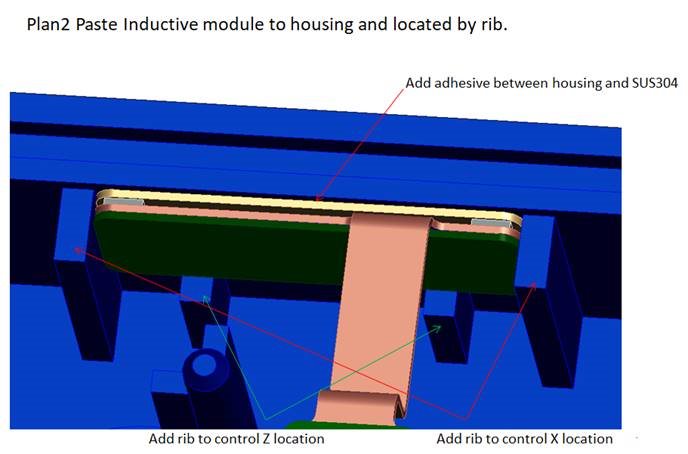

3.The following is a more detailed plan 2 picture, FYR.