Other Parts Discussed in Thread: DRV5013

Dear, Sir.

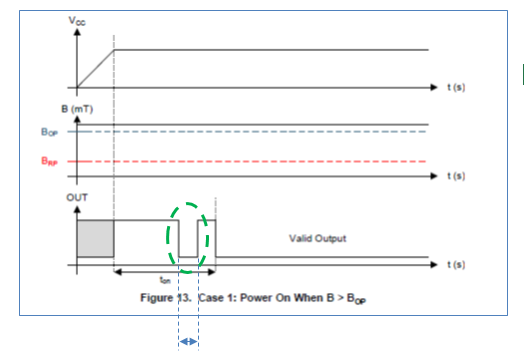

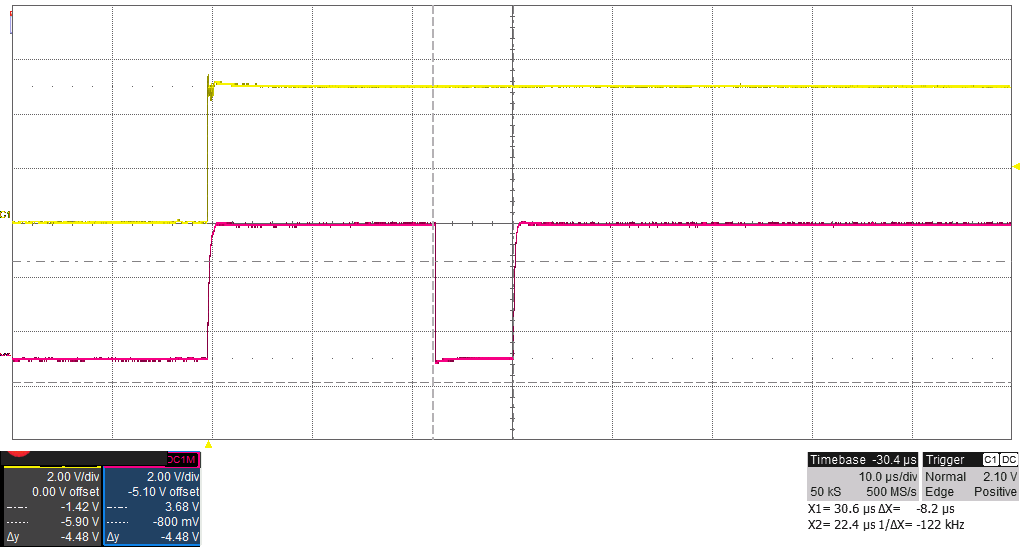

tON typical & maximum values are defined on the datasheet, page 6.

My customer is asking the duratuion of ON=Low after power-up.

Is it possible to clarify & assure about such duration?

Please give your advice.

Best Regards,

H. Sakai