Other Parts Discussed in Thread: DRV5056, DRV5057

Dear,

We are planning to use DRV5055 Sensor ,i already used the DRV5053EAQDBZR (EA: +45 mV/mT) Sensor but wasnt able to get the sensing range.

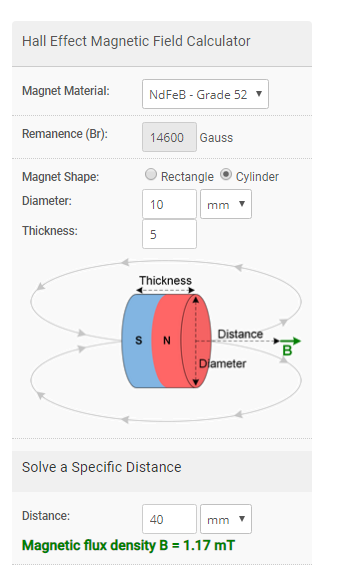

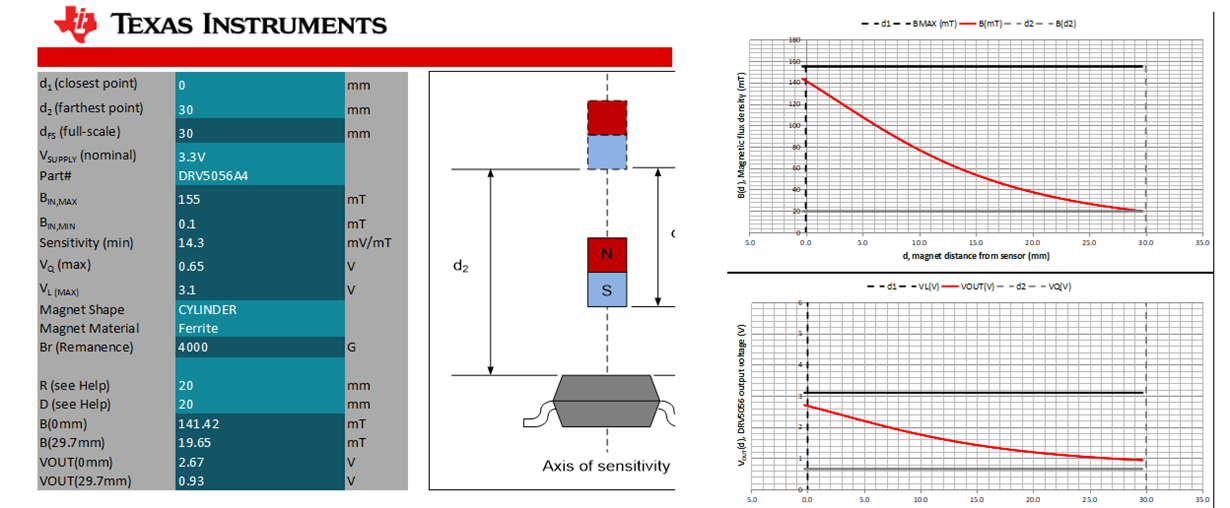

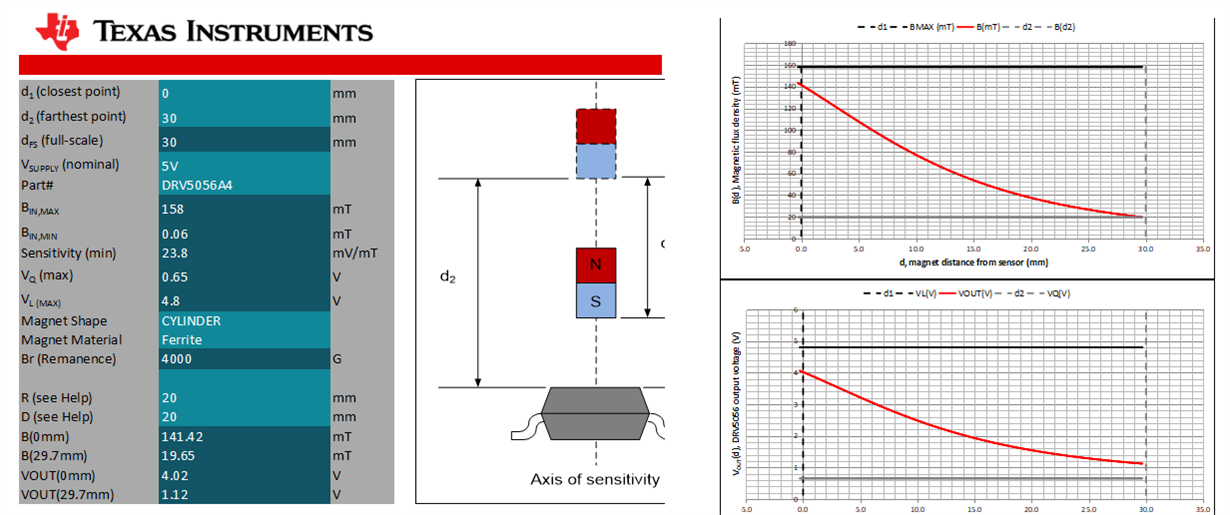

In our application we want a sensing range of 40 mm ,the magnet we are using are N52 Grade 10x5 mm (Dia x Thickness) magnet and accordingly to that i have calculated the magnetic field with the help of the Magnetic field calculator and getting a value of B=1.17 mT :

Below is my query which i would like to ask :

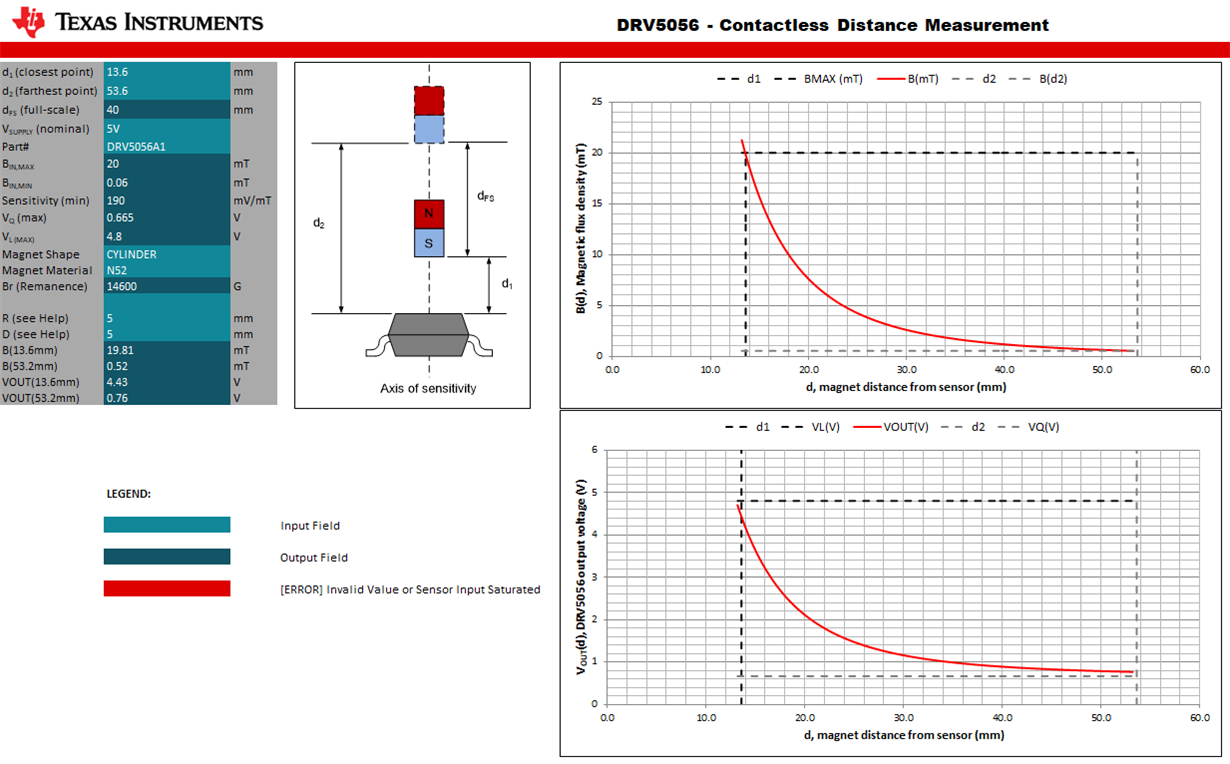

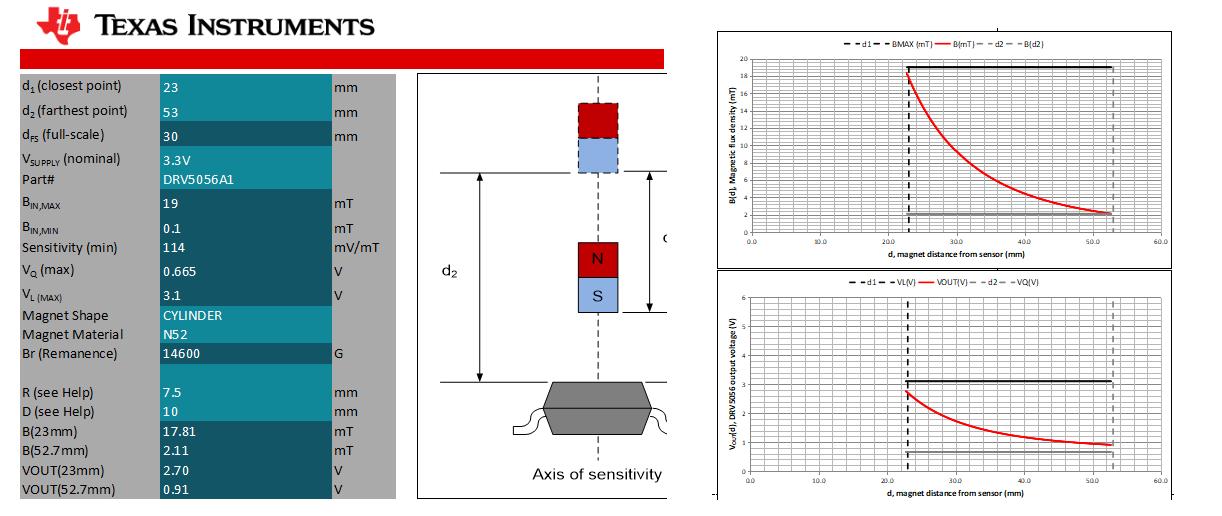

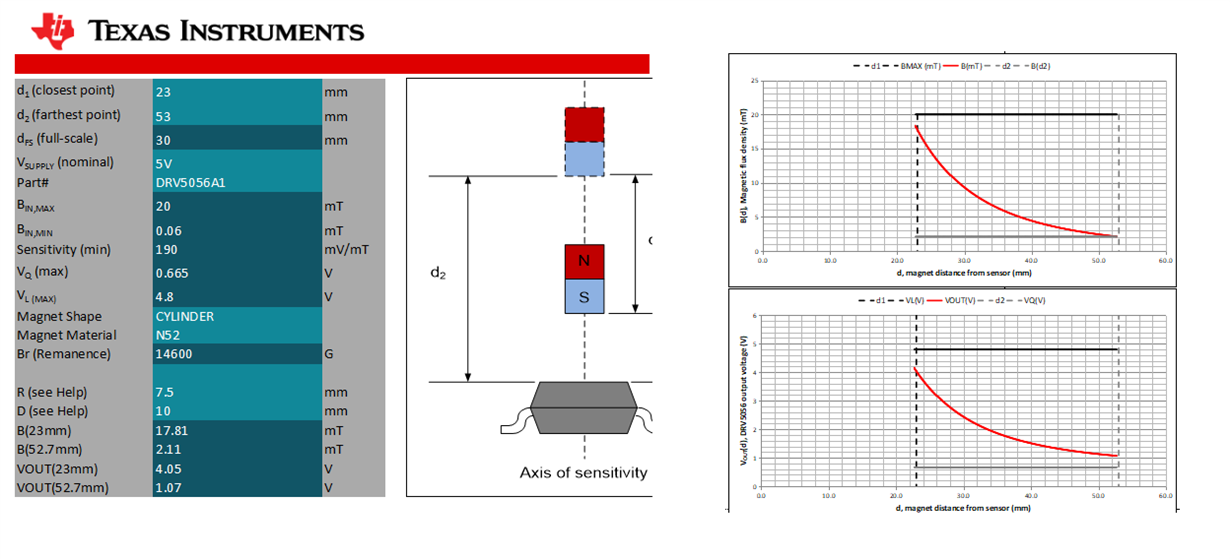

1)Will the DRV5055 Sensor sense from the 40 mm distance...?

2)For better clarity which parameter specifies sensing range of the IC ?What is the relation with the gain..?

Also please suggest any other IC which would meet our requirement,Your help would be highly appreciated..!!