Other Parts Discussed in Thread: FDC1004, TDC1011

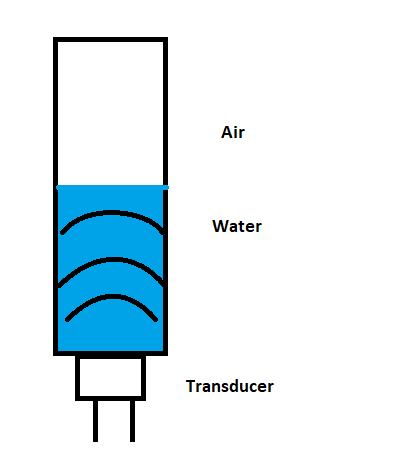

I want to measure liquid level in very small tubes - 5 mm diameter, 10 mm depth. The type of liquid can vary. I'm considering an ultrasonic approach. From what I've read, I need a bistatic transducer configuration to eliminate the dead zone. Would you know of any transducers that would work in this application?