Other Parts Discussed in Thread: TUSS4470, TDC1011, PGA460, BOOSTXL-TUSS4470

Hallo,

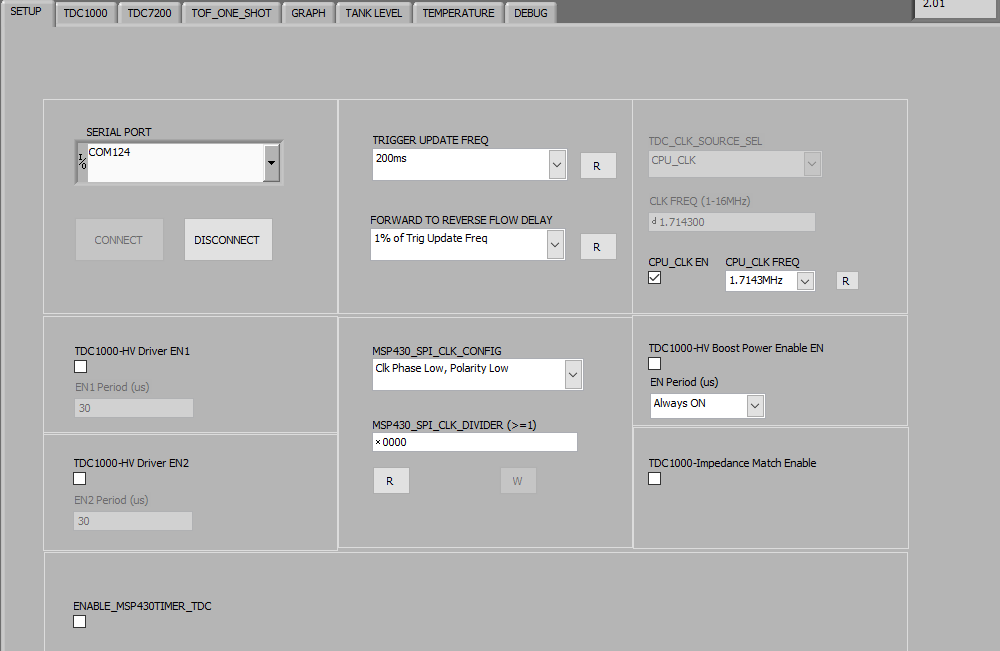

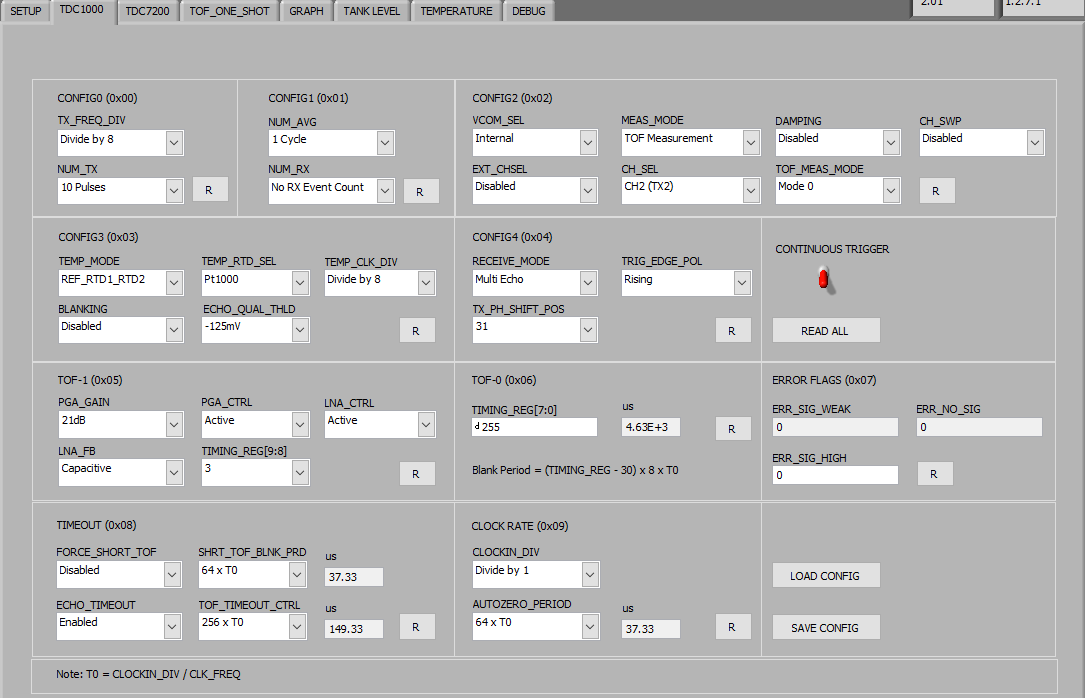

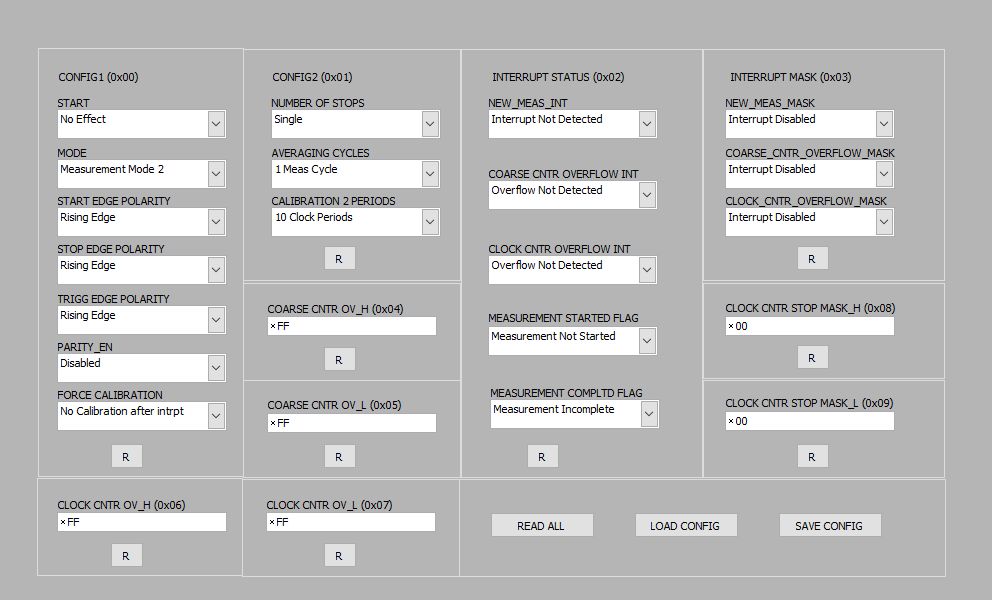

I bought the TDC1000-TDC7200EVM a while ago. Now I finaly got time to try it out. I followed every step in the "TDC1000-TDC7200EVM User’s Guide ". I got the GUI running, but after the firmware update I got no signals from the device. I maesured and there was only a start Signal. After than resetting the TDC1000 via the GUI debug tab I finaly got Signals, but they were constant. I tried mouting the transducer on a sutible container an filling it with water, but i still got the same values. That made no sense. I tried playing with the settings, but I still dit not get anny usefull data. Reinstaling everything changed nothing.

Here are the Registersettings and the result I get.

I realy hope you can help me out.

Tobias