Hello. I am Terry.

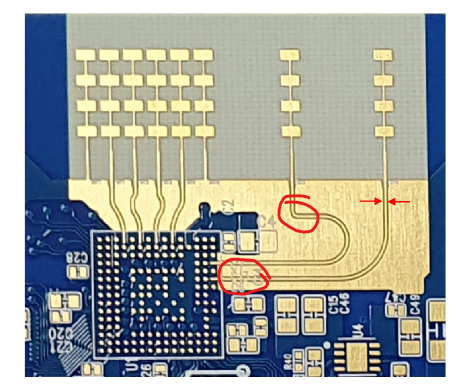

I designed a PCB using the IWR1642 chip.

When designing the PCB, I used the "Rogers4835 Low pro" product.

However, I bought Rogers 4835 Low pro, but H/H instead of 1/H. Because 1/H was very difficult to get.

And I purchased ITEQ180A 28mil core 1/1 products, IT 180A Prepreg 1080 and Iteq 180A 4mil core 1/H.

And although the PCB was manufactured, it was processed with gold plating because it was not possible to do immersion silver plating process.

After that, I downloaded the People count program to the IWR1642 and verified the performance, but it resulted in poor cloud points than the IWR1642 Boost board.

I think that there is three different factors in our PCB compared with 1642 Boost.

1. NOT immersion silver plating (used gold)

2. NOT I/H (used H/H)

3. a litter bit different Via placement, but it is within the error that TI offered (0.1~0.3mm), see attached files

what is the main factor affecting the poor performance of our board? any futher considerations that I don't know?

please let me know...