Hi,

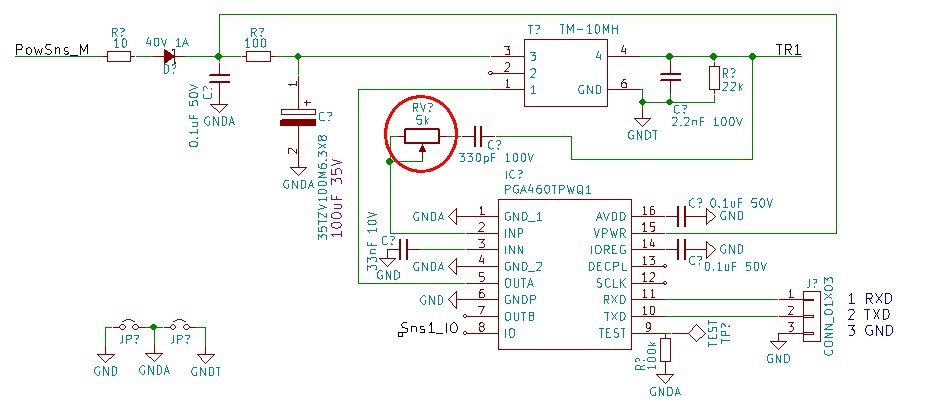

I like to put a veriable resistor between transducer and PGA460 INN for fine adjustment by hand.

It is needed for covering tansducer's gain variation.

Although it needs internal impedance and gain balance info of PGA460.

As much as I see the recommended value in PGA460-Q1 doc page 107,

it tells Rinp is 3k ohm.

So it is supposed that 5k ohm variable resistor is suitable since it will make 2.5k ohm center resistance that is close to the recommendation.

Is all above suitable for sensing fine tune by hand for PGA460?

Best Regards,

Andy